Intelligent door lock speed reducer with centrifugal clutch

A technology for centrifugal clutches and smart door locks, applied in clutches, automatic clutches, non-mechanical transmission-operated locks, etc., can solve the problems of complex structure, high cost, and large volume of the reducer, and achieve simple structure, reduced space size, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

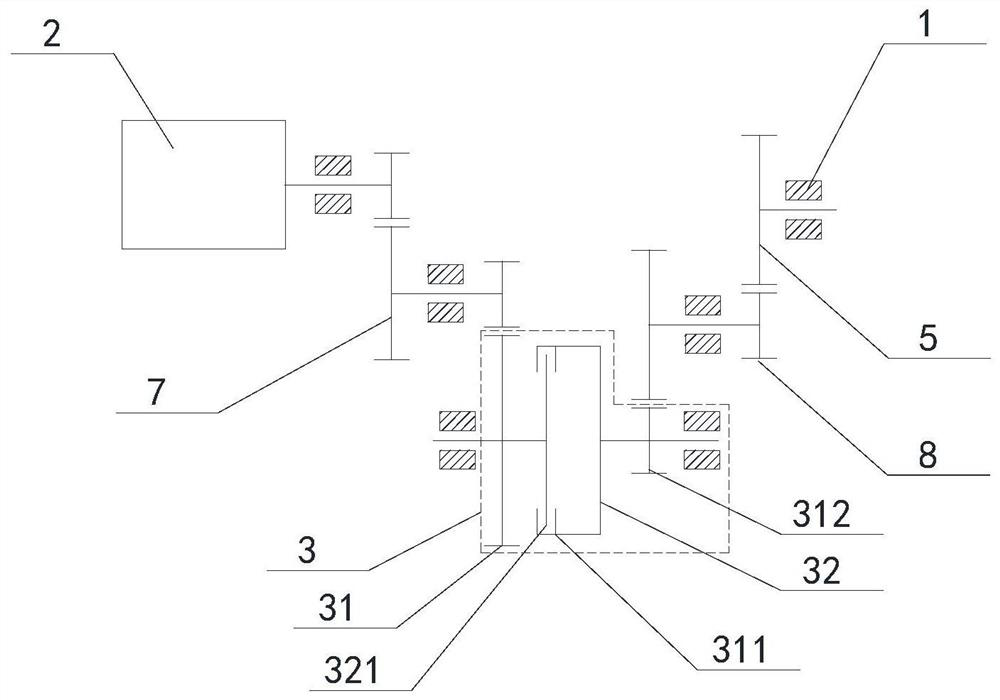

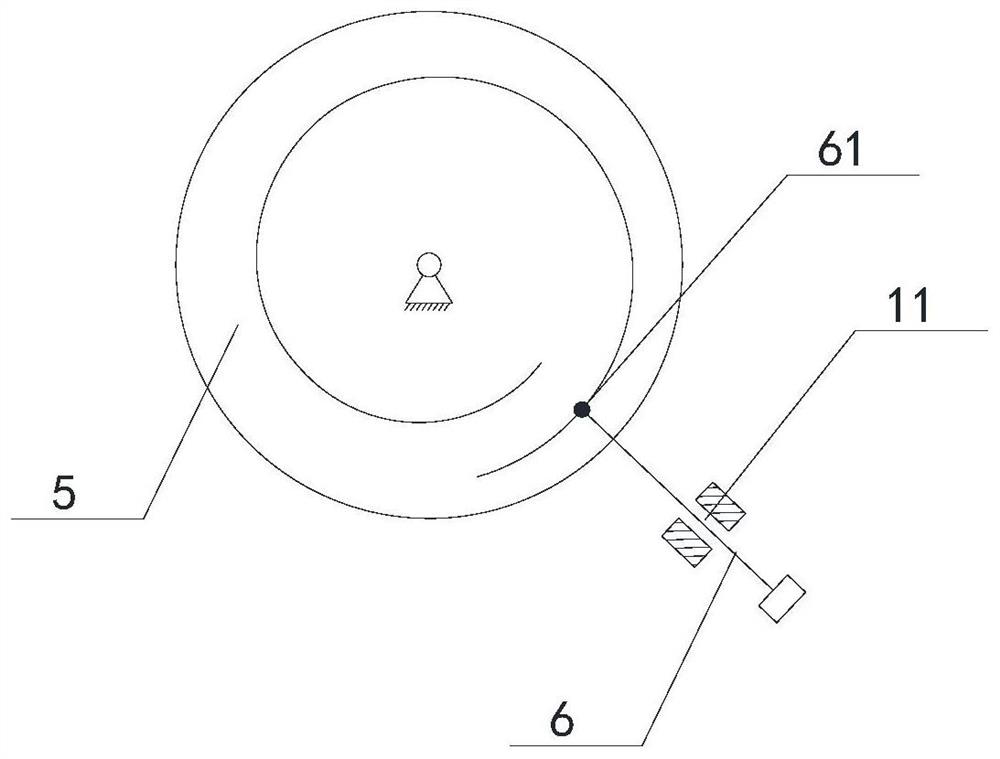

[0051] The intelligent door lock reducer with centrifugal clutch provided by the present invention includes a reducer housing 1, a drive motor 2, a centrifugal clutch 3 and a state mechanism, the state mechanism includes an output gear 5 and a slider 6, and the drive motor 2 is arranged on the reducer casing On the body 1, the driving motor 2 and the output gear 5 are connected with the centrifugal clutch 3 respectively.

[0052] The centrifugal clutch 3 includes a centrifugal driven wheel 31 and a centrifugal driving wheel 32 arranged in rotation. The centrifugal driven wheel 31 is provided with a first limiting portion 311 and a driven side gear 312 is provided on its outer surface. A centrifugal elastic component is disposed inside the centrifugal driving wheel 32 , and a second limiting portion 321 is disposed on a side of the centrifugal elastic component. The outer surface of the centrifugal driving wheel 32 is provided with a driving side gear 322, the driving side gear...

Embodiment 2

[0061] Such as Figure 5 and Figure 6 As shown, the driven side gear 31 is a cylinder with the opening downward, the driven side gear 312 is arranged on the top surface of the cylinder, the inner surface of the cylinder is provided with a limiting groove 3110, and the top surface of the cylinder is provided with an upper connection. Column 314.

[0062] The driving side gear 32 includes a bottom plate 325 and a supporting wall 326 , the side of the bottom plate 325 is provided with a driving side gear 322 , and the driving side gear 322 meshes with the first reduction assembly 7 . A lower connecting column 327 is provided on the center of the top surface of the bottom plate 325 , and when the driven side gear 312 and the driving side gear 322 are fastened together, the lower connecting column 327 abuts against the upper connecting column 314 . The support wall 326 is disposed on the top surface of the bottom plate 325 , and the notch 3250 is disposed on the support arm 326 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com