An underground building anti-floating pressure relief hole plugging structure and its construction method

A technology for underground construction and construction methods, applied in infrastructure engineering, construction, protection devices, etc., can solve the problems of difficult sealing, easy formation of gaps, poor sealing effect, etc., to ensure construction quality and avoid leakage. , the effect of extending the seepage path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

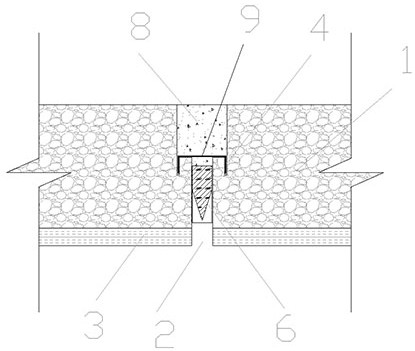

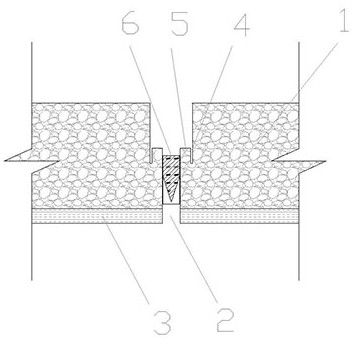

[0033] Figure 1 to Figure 4 Shown is an underground building anti-floating pressure relief hole plugging structure, including a concrete cushion 3, a concrete floor layer 1 and a pressure relief hole 2, the upper part of the pressure relief hole 2 has an annular platform, and it is characterized in that the annular platform There is an annular groove 4 on the top, and a sealing plug 6 is arranged in the pressure relief hole 2. There is a water-stop buckle 9 above the sealing plug 6, and the water-stop buckle 9 fits in the annular groove 4 , the top of the water-stop buckle 9 is a concrete sealing layer 8 .

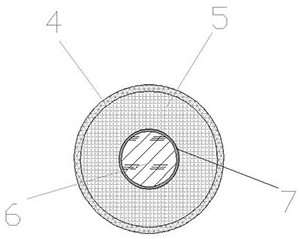

[0034] Such as image 3 As shown, the annular groove 4 and the annular platform are arranged concentrically. The arrangement of the annular groove 4 makes the annular platform form an annular boss 5, and the two are arranged concentrically, so that the thickness of the annular boss 5 is more uniform and the strength is higher.

[0035] The outside of the sealing plug 6...

Embodiment 2

[0041] The construction method of the anti-floating pressure relief hole plugging structure of the above-mentioned underground building comprises the following steps:

[0042] (1) The upper part of the pressure relief hole 2 is provided with an annular platform on the concrete floor layer 1;

[0043] (2) Open an annular groove 4 on the annular platform;

[0044] (3) Put the plug 6 tightly into the pressure relief hole 2;

[0045] (4) Press the water stop buckle 9 into the annular groove 4;

[0046] (5) Pour concrete above the water-stop buckle 9 to seal it.

[0047] In the step (3), the rubber tube 7 is tightly set on the sealing plug 6, and then it is smashed into the pressure relief hole 2 to leave a hole.

[0048] In step (3), the water in the opening of the pressure relief hole 2 and the annular groove 4 is cleaned first, and then the plugging cement slurry is poured above the sealing plug 6 until the annular groove 4 is at least filled.

[0049] The concrete in the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com