Drilling depth and verticality measuring device and using method thereof

A technology for drilling depth and measuring devices, which is applied in the field of verticality measuring devices and drilling depths, and can solve problems such as increased engineering volume and cost, excessive deviation of verticality accuracy of hole walls, size violation of prefabricated piles or cast-in-situ piles, etc. , to avoid the increase of engineering quantity, facilitate installation and fixation, and save construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

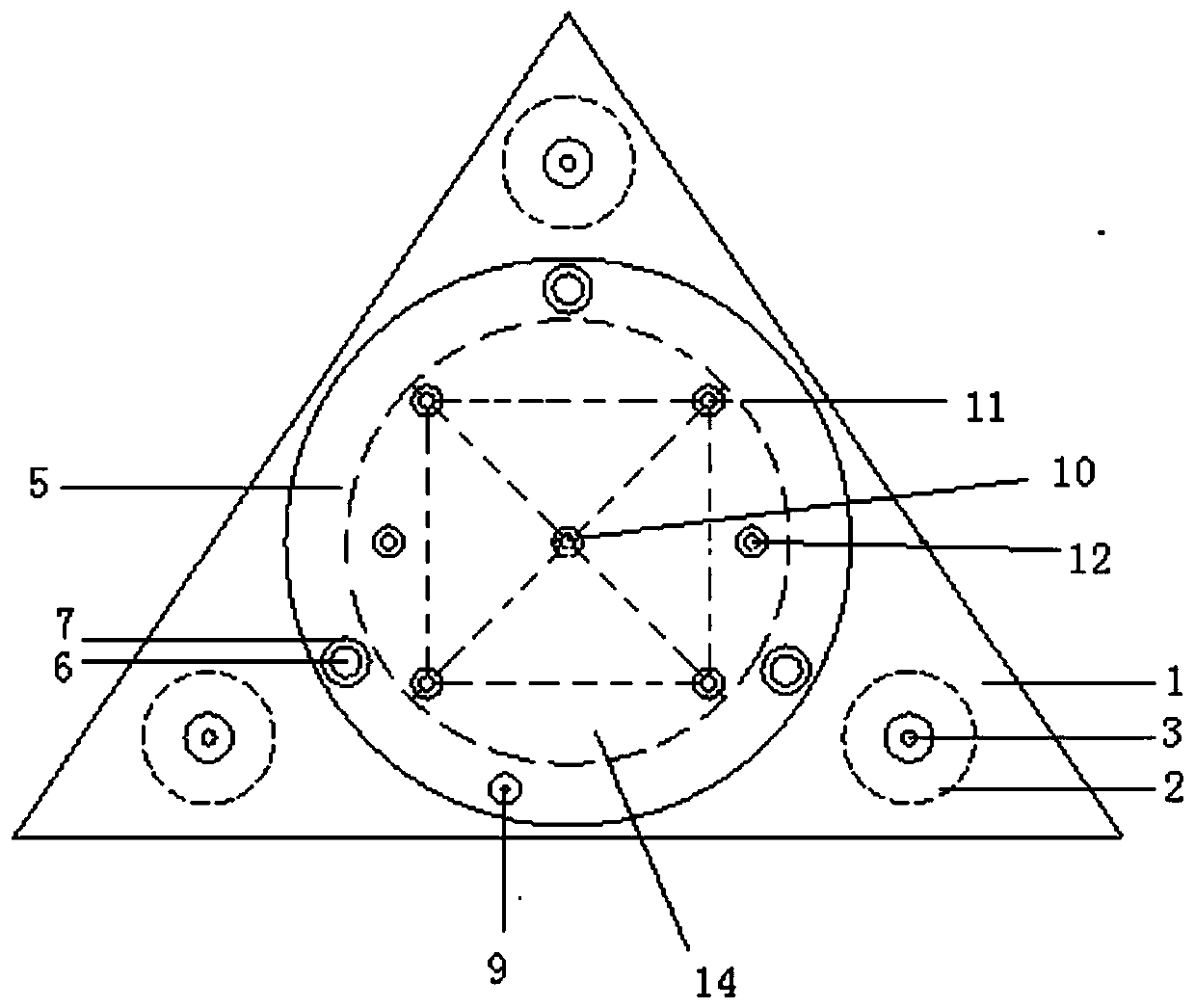

[0047] This embodiment discloses a method for using a drilling depth and verticality measuring device, comprising the following steps:

[0048] Step 1: According to the set position, use the total station to measure and position the point, determine the fixed point on the basis of the surrounding of the drill hole, and fix the positioning nail at the fixed point.

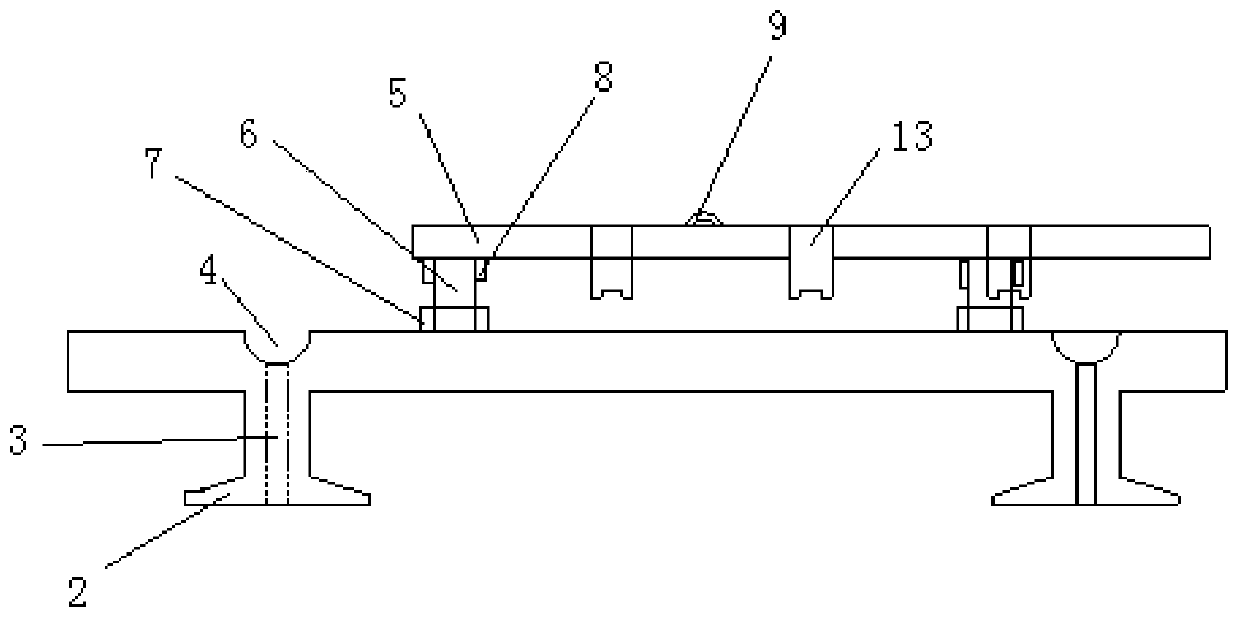

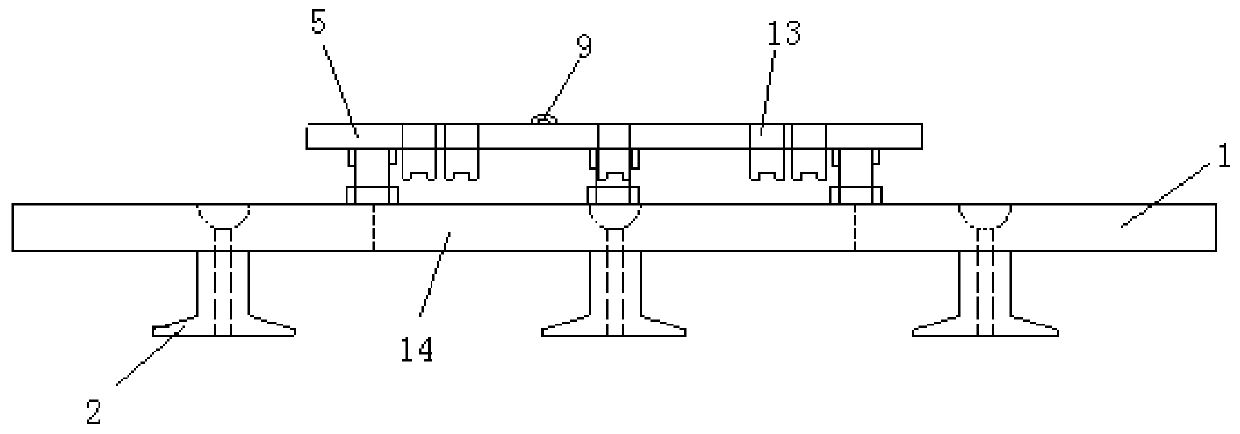

[0049] Step 2: According to the fixed point determined in step 1, insert the positioning nail into the positioning hole of the foot, fix the fixing plate on the foundation around the drilling hole through the foot, and set the fixing plate and the drilling hole coaxially.

[0050] Step 3: Turn the screw, the screw moves along its own axis, drives the support plate for leveling, observe the position of the bubble in the bubble level at any time, and turn the corresponding screw until the bubble in the bubble level is in the middle position, and the support plate is adjusted to the level state.

[0051] Step 4: Start...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com