Freely-cut knitted fabric with polyester on one side and pure spandex on other side and production method of knitted fabric

A technology of knitted fabrics and polyester, applied in knitting, weft knitting, decorative textiles, etc., can solve problems such as poor moisture absorption and breathability, poor anti-skid performance, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

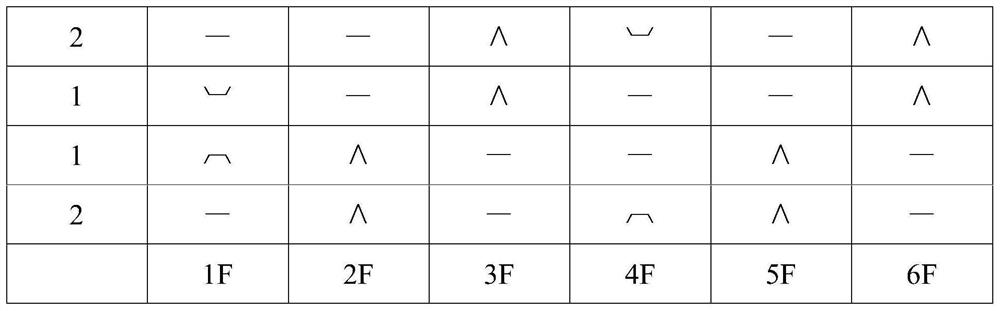

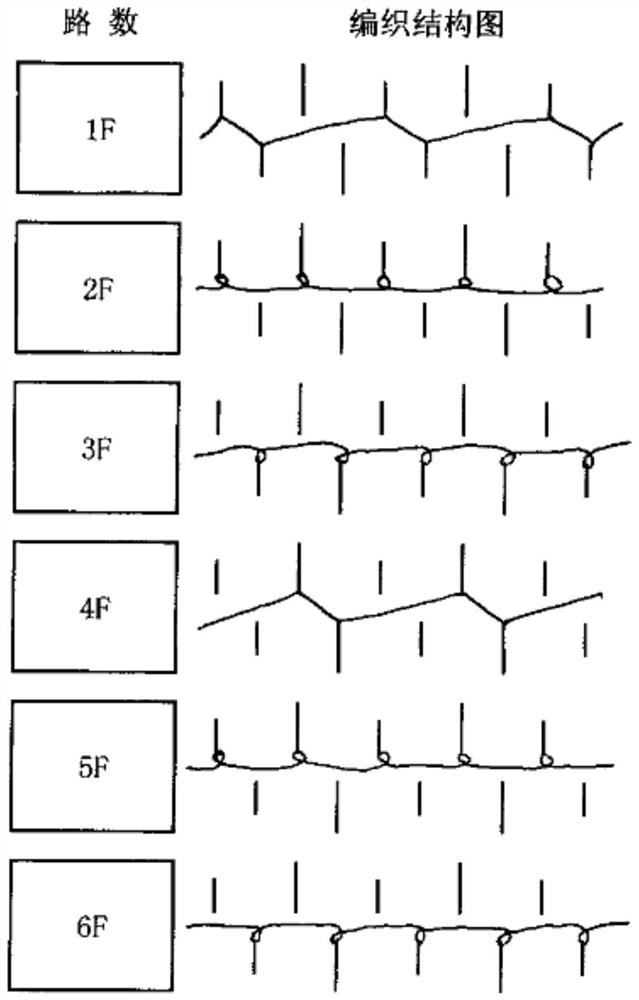

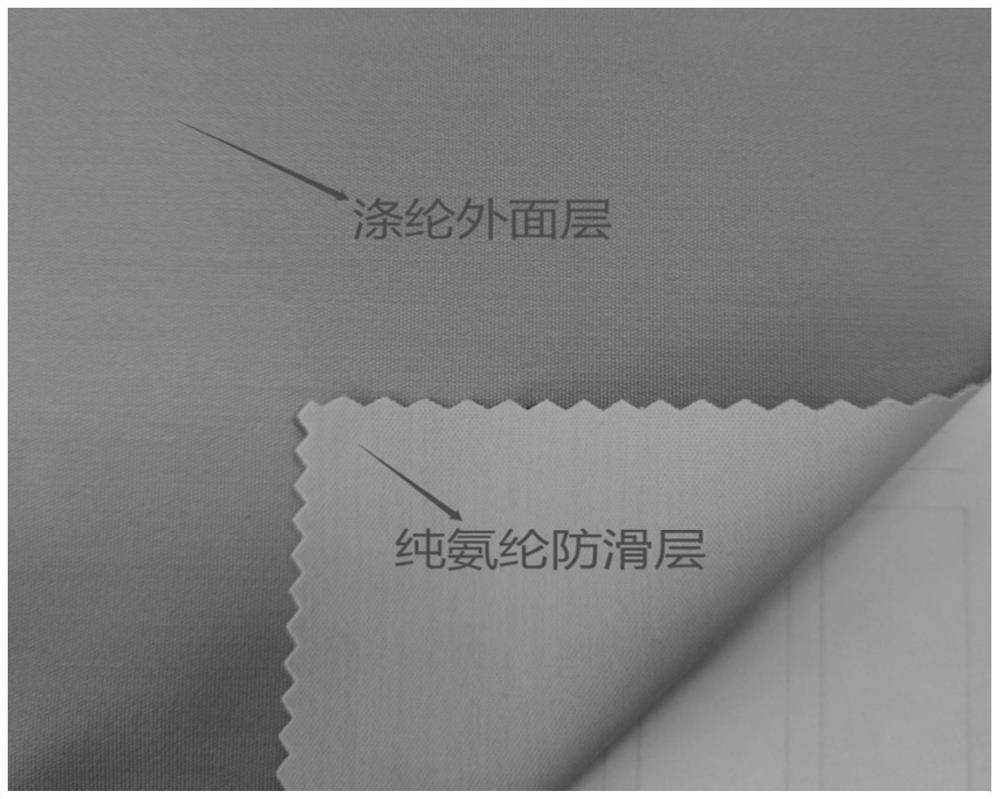

[0017] refer to Figure 1 ~ Figure 3 . Knitted fabric with polyester on one side and pure spandex on the other hand, including the fabric body. The fabric body includes polyester outer layer, pure spandex anti-skid layer and connecting layer. The connection layer is arranged in 2 ways, 1 with 1 flat. The polyester outer layer and the pure spandex anti-skid layer are respectively located on both sides of the connection layer, and are connected through the connection layer. The raw material of the polyester outer layer is 50D / 36F low elastic semi-gloss moisture absorption The veil of sweat-wicking polyester DTY (Draw Texturing Yarn) and the liner yarn of 70D spandex, the raw material of pure spandex anti-skid layer is 70D spandex non-slip yarn, and the raw material of connecting layer is 70D spandex connecting yarn. Among them, the veil of 50D / 36F low-elastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com