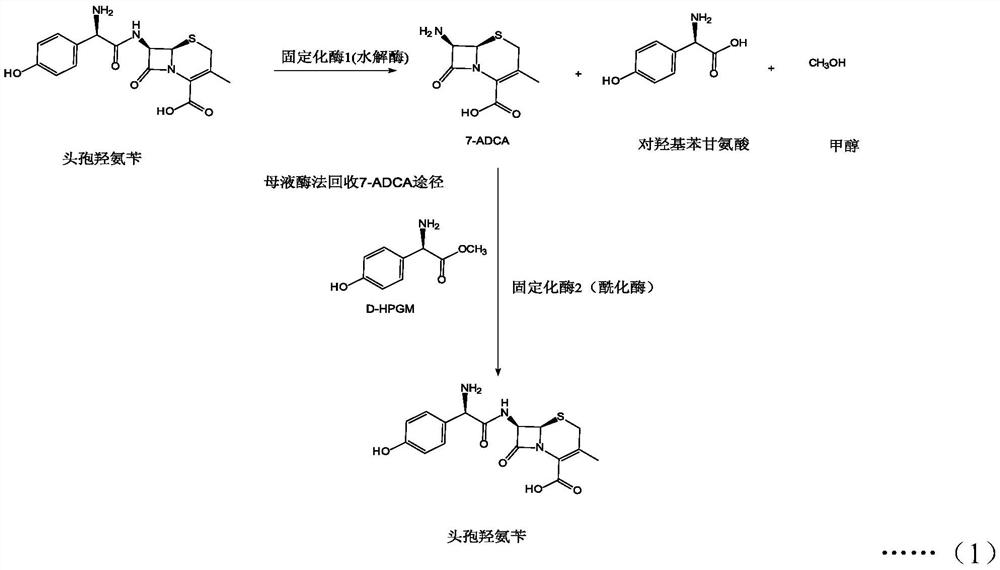

7-ADCA recovery method

A technology of 7-ADCA and recovery method, applied in the field of 7-ADCA recovery, can solve the problems of low yield and low recovery rate of cefadroxil naphthol complex, and achieves convenient operation, obvious safety and environmental protection benefits, and improved product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

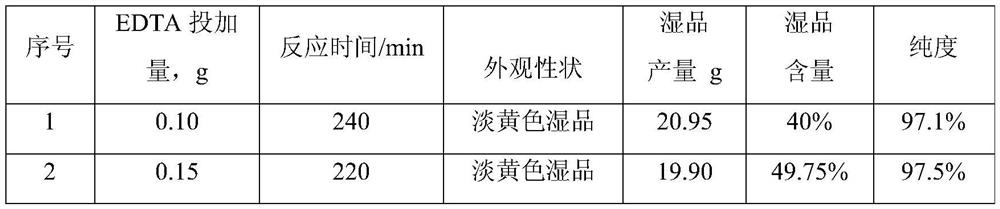

[0032] Example 1: Influence of additive dosage on reaction effect in pretreatment

[0033] In the pretreatment process, there are two main additives: EDTA and sodium bisulfite.

[0034] In the following, in combination with the specific recovery process, the experiment is first carried out on the influence of the dosage of EDTA.

[0035] (1) Add 1000ml of cefadroxil crystallized mother liquor prepared by the enzymatic cefadroxil process route into the reactor with stirring, the concentration of cefadroxil is about 15mg / ml, heat up to 15°C, control the dosage of EDTA, sulfurous acid Sodium hydrogen 0.20g, adjust the pH of the mother liquor to 7.0 with ammonia water, stir for later use.

[0036] (2) A self-designed bioreactor, put an appropriate amount of immobilized biological enzyme 15g into the bioreactor, put it into the feed liquid configured in (1), use ammonia water for enzyme reaction to maintain pH 7.0, temperature 15°C, every 1 hour Sampling inspection, using high pe...

Embodiment 2

[0053] Example 2: Influence of parameters on reaction effect in pretreatment

[0054] Enzyme-catalyzed reactions need to be at a suitable temperature to exhibit the best catalytic activity. If the temperature is too low, the enzyme activity is not high. The main temperature affects the contact probability between the substrate molecule and the catalytic center of the enzyme activity. The higher the temperature, the more intense the molecular motion and the higher the probability of contacting the catalytic center. On the other hand, if the temperature is too high, It will also change the spatial conformation of the enzyme molecule, denaturing and inactivating. At the same time, too high temperature leads to accelerated degradation of cephalosporins and darker color, so it is necessary to pretreat the temperature of the feed liquid in an appropriate range. The pretreatment of this step is to provide suitable conditions for the next enzyme reaction, so the temperature is tested...

Embodiment 3

[0081] Example 3: Effect of Immobilized Enzyme Dosage on Reaction Effect

[0082] As a catalyst, the immobilized enzyme provides an active catalytic center during the reaction process. The amount of input affects the reaction time of the enzyme and is a key factor in product quality and cost.

[0083] In the following, combined with the specific recovery process, the experiment is first carried out on the influence of the dosage of immobilized enzyme.

[0084] (1) Add 1000ml of cefadroxil crystallized mother liquor prepared by the enzymatic cefadroxil process route into the reactor with stirring, the concentration of cefadroxil is about 15mg / ml, heat up to 20°C, control the dosage of EDTA, sulfurous acid Sodium hydrogen 0.80g, adjust the pH of the mother liquor to 7.0 with ammonia water, stir for later use.

[0085] (2) For a self-designed bioreactor, put an appropriate amount of 12.75g to 45g of immobilized biological enzyme into the bioreactor, put it into the feed liquid c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com