Water and electricity integrated pipe and cleaning machine

An integrated tube, water and electricity technology, applied in the field of cleaning machines, can solve problems such as material breakage, and achieve the effect of not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

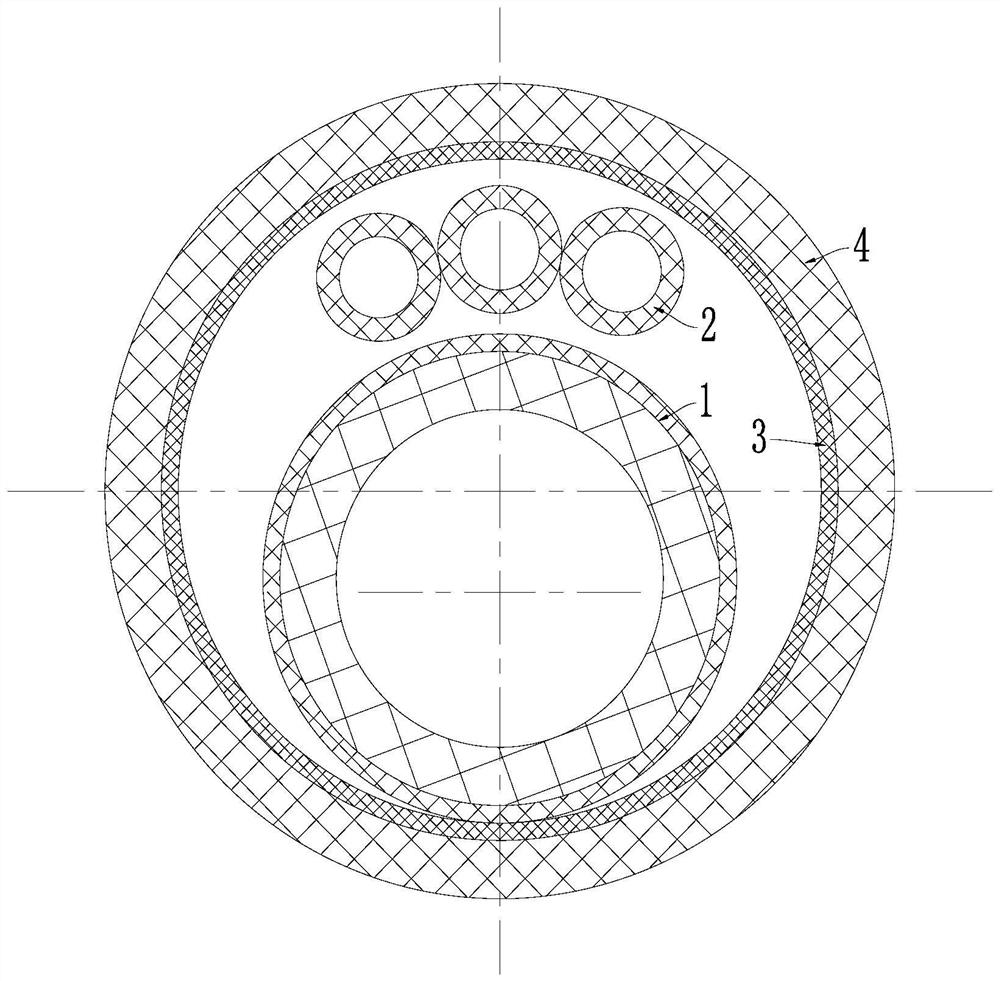

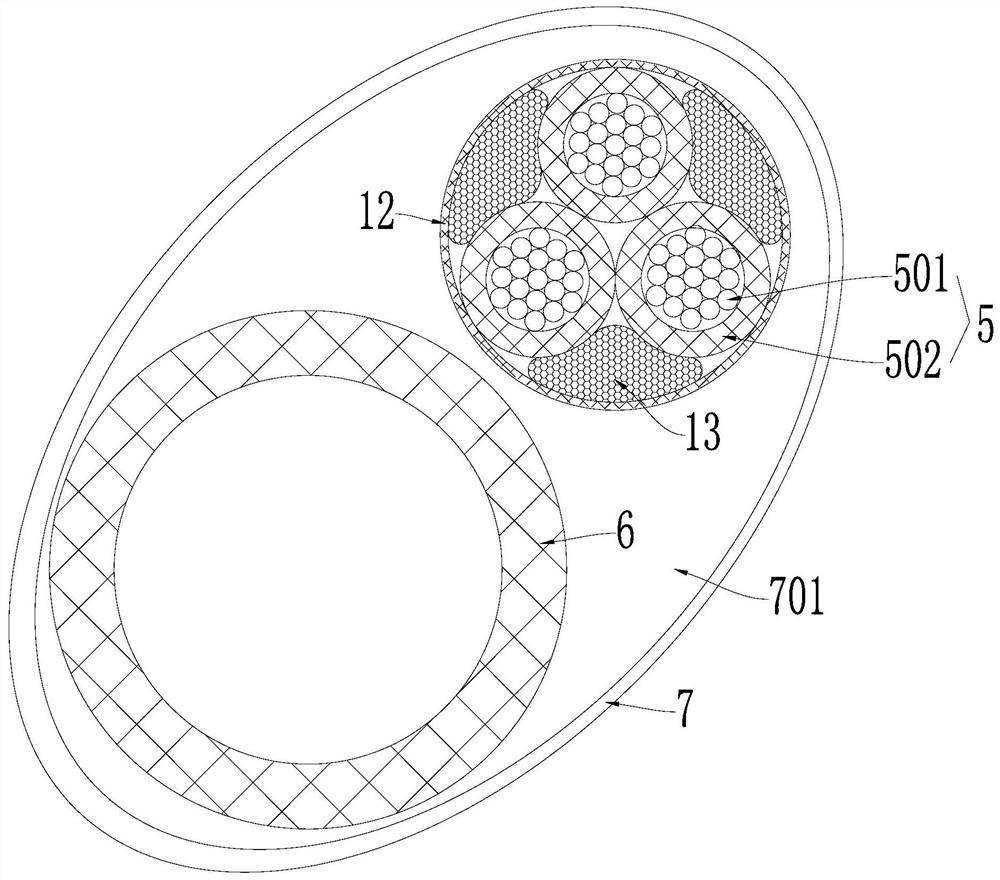

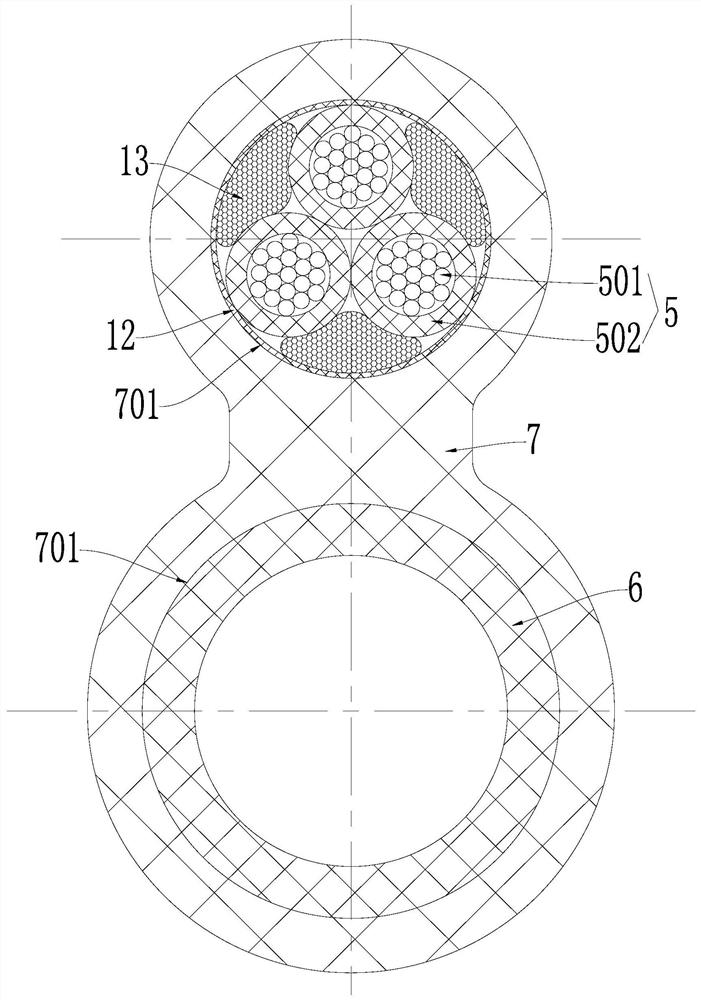

[0044] Embodiments of the present invention provide a water and electricity integrated pipe and a washing machine using or configuring the water and electricity integrated pipe. Such as Figure 2 to Figure 4 As shown, the water and electricity integrated pipe includes: a wire 5 for transmitting signals, a first flow channel 6 arranged in parallel with the wire 5 and used for fluid medium circulation, wrapping the wire 5 and the first flow channel 6 so that the wire 5 and the first flow channel 6 The first wrapping layer 7 that becomes one. The cleaning machine includes a host machine and a spray gun which are set separately. The main engine includes a pump body and a motor connected with the pump body to drive the pump body to work. The spray gun includes a second channel for fluid medium circulation and a control module for controlling the operation of the motor. The host and the spray gun are connected through the water and electricity integrated pipe of this embodiment. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com