Oxygen generator solenoid valve control structure and control system thereof

A control structure and solenoid valve technology, applied in valve details, valve devices, inorganic chemistry, etc., can solve problems such as the greater influence of the altitude of the oxygen generator, the impact on the efficiency of the oxygen generation system, and the failure of the oxygen generation system to work normally. Achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

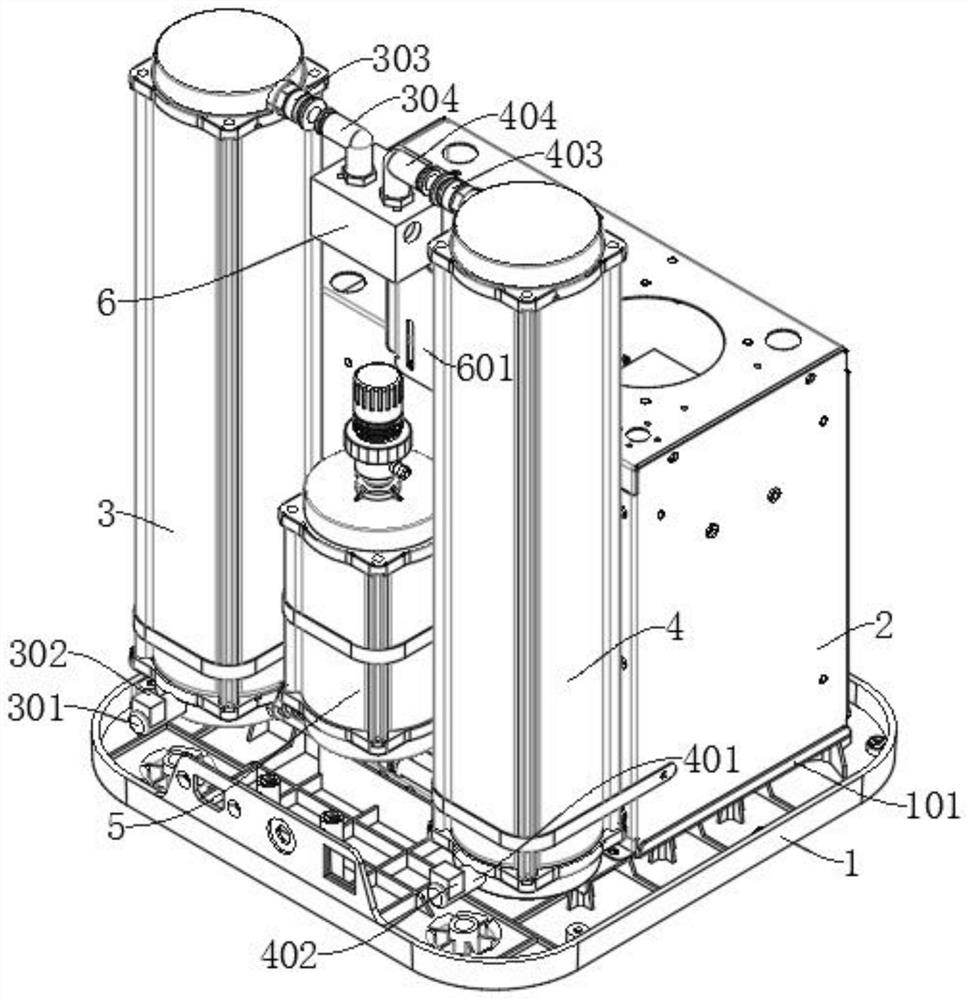

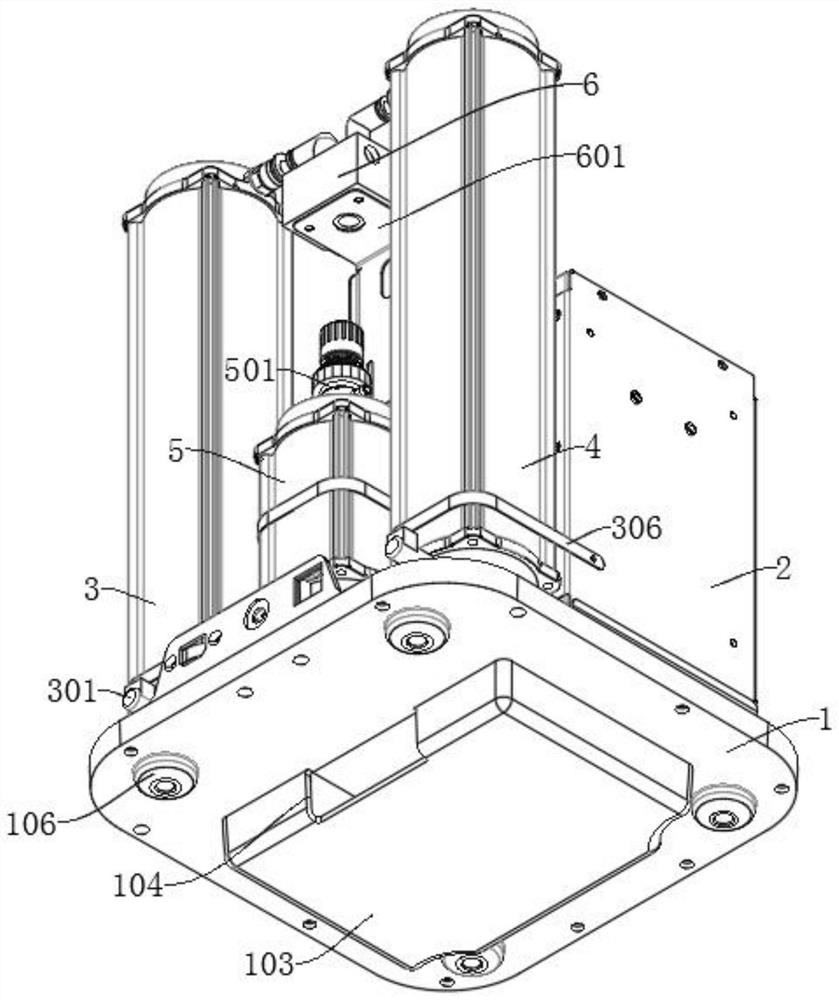

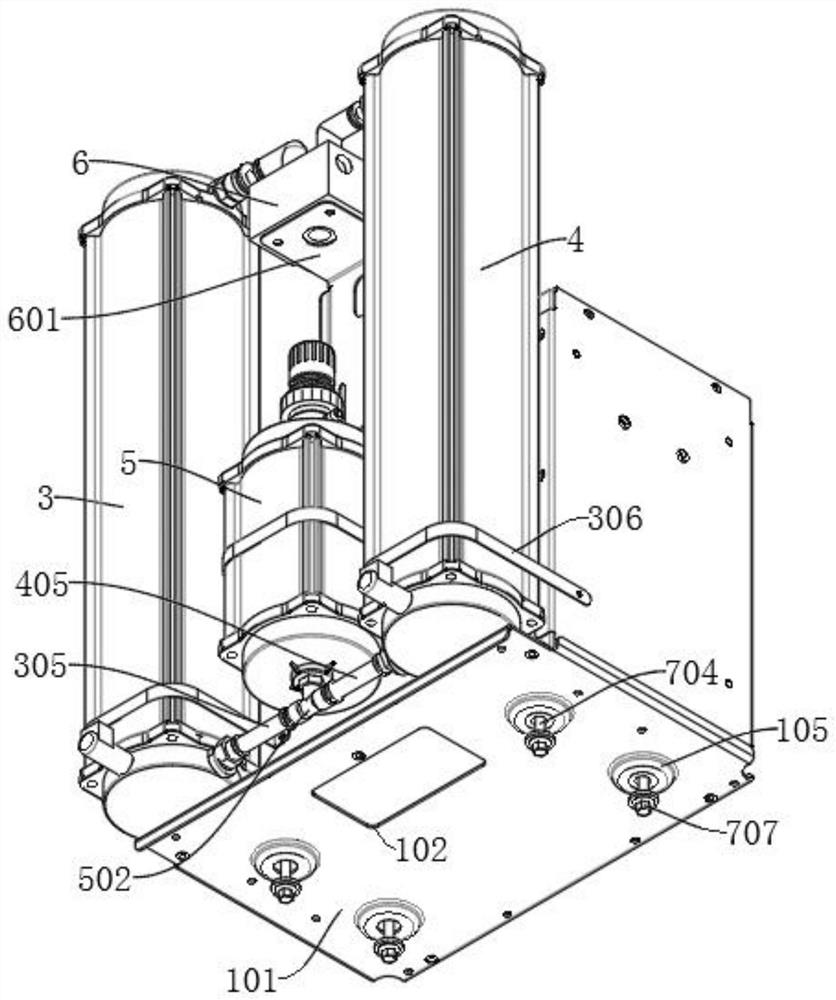

[0035] refer to Figure 1-Figure 5 , a solenoid valve control structure for an oxygen generator, including a base 1 and a housing 2, the housing 2 is connected to the base 1, and the housing 2 is connected with an air compressor body 7 for oxygen production operation, and a molecular sieve is also provided Tower A3 and molecular sieve tower B4, the bottoms of molecular sieve tower A3 and molecular sieve tower B4 are respectively equipped with oxygen output tube A301 and oxygen output tube B401, and oxygen output tube A301 and oxygen output tube B401 are respectively equipped with air pressure sensor A302 and The air pressure sensor B402, by setting the air pressure sensor A302 and the air pressure sensor B402 at the bottom, controls the operation of the solenoid valve 6 of the system by sampling the pressure of the oxygen output end, and improves the output efficiency of oxygen; the system solenoid valve 6 is arranged on the top of the housing 2 , the system solenoid valve 6 i...

Embodiment 2

[0040] refer to Figure 4 and Figure 5 , a solenoid valve control structure for an oxygen generator, including a base 1 and a housing 2, the housing 2 is connected to the base 1, and the housing 2 is connected with an air compressor body 7 for oxygen production operation, and a molecular sieve is also provided Tower A3 and molecular sieve tower B4, the bottoms of molecular sieve tower A3 and molecular sieve tower B4 are respectively equipped with oxygen output tube A301 and oxygen output tube B401, and oxygen output tube A301 and oxygen output tube B401 are respectively equipped with air pressure sensor A302 and The air pressure sensor B402, by setting the air pressure sensor A302 and the air pressure sensor B402 at the bottom, controls the operation of the solenoid valve 6 of the system by sampling the pressure of the oxygen output end, and improves the output efficiency of oxygen; the system solenoid valve 6 is arranged on the top of the housing 2 , the system solenoid val...

Embodiment 3

[0044] refer to figure 1 , a solenoid valve control structure for an oxygen generator, including a base 1 and a housing 2, an air compressor body 7 is connected to the housing 2, a molecular sieve tower A3 and a molecular sieve tower B4 are connected to the housing 2, and the molecular sieve tower A3 and the molecular sieve The bottom of the tower B4 is respectively provided with an oxygen output pipe A301 and an oxygen output pipe B401, and an air pressure sensor A302 and an air pressure sensor B402 are respectively arranged on the oxygen output pipe A301 and the oxygen output pipe B401; The solenoid valve 6, the system solenoid valve 6 is connected to the air compressor body 7 through pipelines, the molecular sieve tower A3 and the molecular sieve tower B4 are connected to the system solenoid valve 6, the air pressure sensor A302 and the air pressure sensor B402 are connected to the system solenoid valve 6 signal; A filter 5 is also connected to the body 2, and an air inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com