Nitrogen generation control method for refrigerating and freezing equipment and refrigerating and freezing equipment

A technology of refrigeration and freezing equipment and a control method, which is applied in the field of refrigeration and freezing equipment, can solve the problems of affecting service life, increasing operating time, and high cost, and achieves the effects of avoiding working hours, increasing load, and increasing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

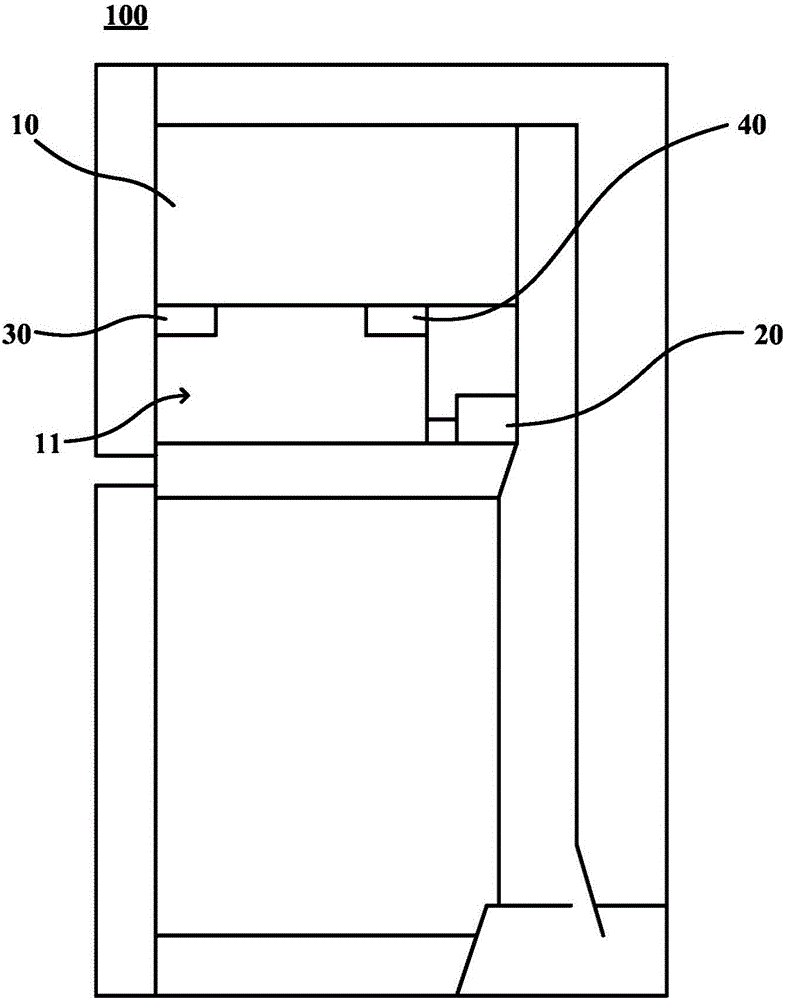

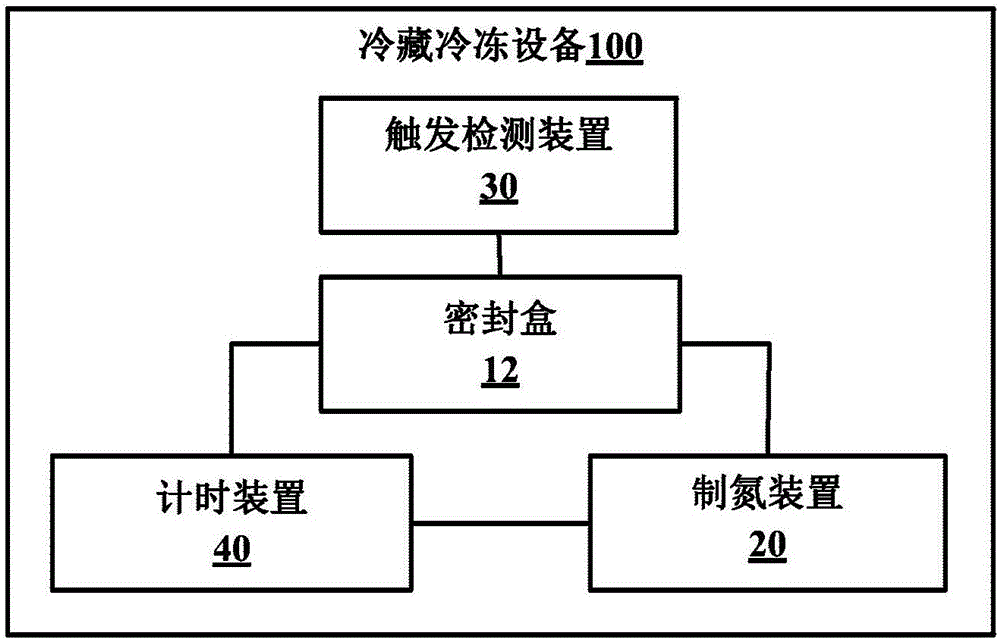

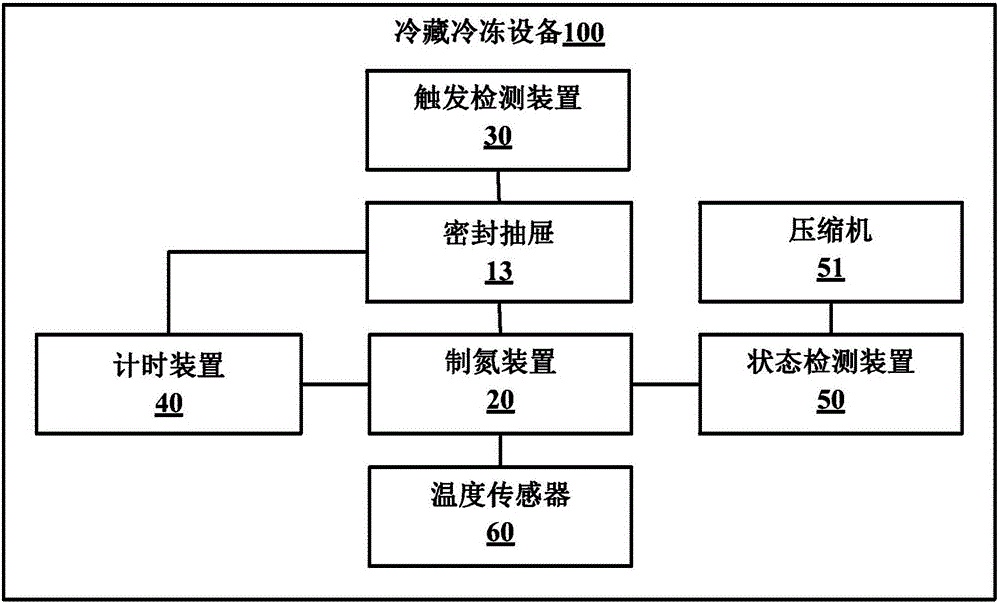

[0026] This embodiment first provides a refrigerating and freezing device 100, figure 1 is a schematic diagram of a refrigerating and freezing device 100 according to an embodiment of the present invention, figure 2 is a schematic block diagram of a refrigerating and freezing device 100 according to an embodiment of the present invention. The refrigerating and freezing equipment 100 may be a refrigerator, a freezer, and the like.

[0027] The refrigerating and freezing equipment 100 of this embodiment has a storage compartment 10, and a sealed space 11 is arranged inside the storage compartment 10. In this embodiment, a sealed box 12 is arranged in the storage compartment 10, and the above-mentioned sealed space 11 can be formed by The sealed box 12 is defined, and in some optional embodiments, the above-mentioned sealed space 11 may also be defined by a sealed drawer, a sealed tank, a sealed box, and the like. The refrigerating and freezing equipment 100 of this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com