Detachable combined modular tobacco leaf natural gas curing barn

A natural gas, modular technology, applied in the direction of tobacco, tobacco preparation, application, etc., can solve the problems of hidden safety hazards or excess safety, inconvenient disassembly and transfer, low thermal insulation performance, etc., to achieve a balance between fire performance and cost control, improve Construction period and cost, the effect of ensuring fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the present invention is not limited in any way. Any changes or improvements made based on the teaching of the present invention belong to the protection scope of the present invention.

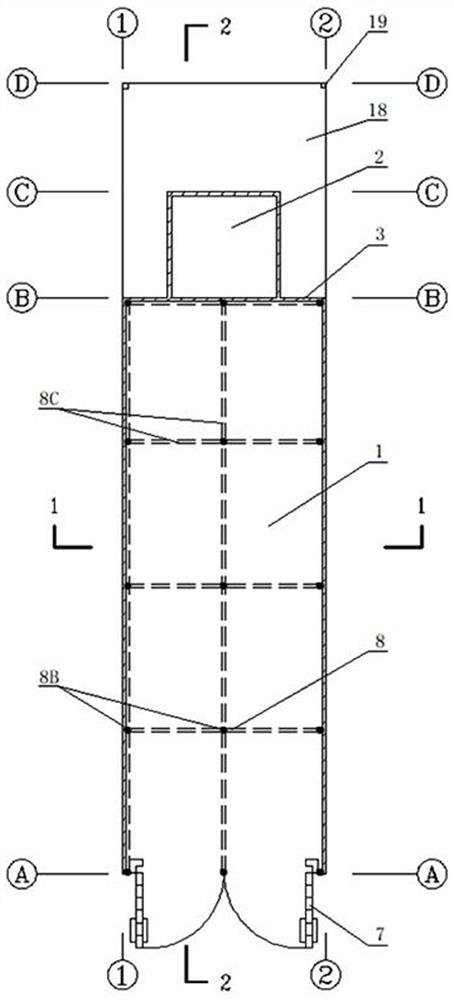

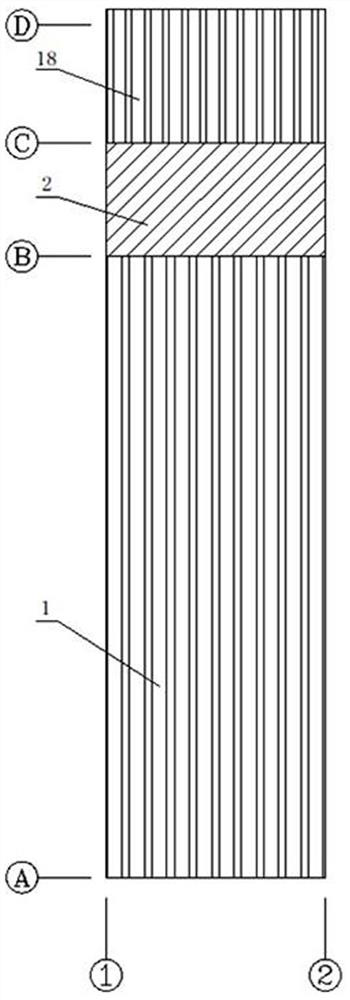

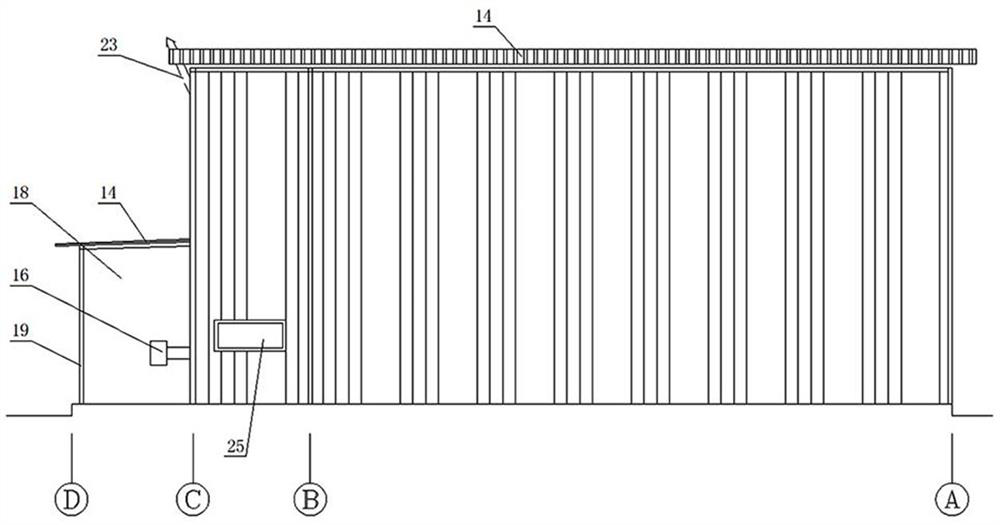

[0031] like Figures 1 to 16 As shown, the present invention includes a smoke-loading chamber 1 and a heating chamber 2. A heat-insulating wall 3 is arranged between the smoke-loading chamber 1 and the heating chamber 2, and air inlets 4 are respectively arranged on the upper and lower parts of the heat-insulating wall 3. , the air return port 5, the heating chamber 2 is provided with a natural gas heating device 6 between the air inlet 4 and the air return port 5, the end wall of the smoke chamber 1 is provided with a smoke door 7, and the smoke chamber 1 is composed of The polyurethane composite board is detachably assembled to form a closed space. The interior of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com