Camera test equipment and camera imaging test method

A technology for testing equipment and cameras, applied in image communication, television, electrical components, etc., can solve the problems of inability to adjust the level of the camera and the imaging angle, low efficiency of the testing process, and low detection accuracy, and achieves a simple and convenient testing method. Improve the efficiency of the test and the accurate effect of the detected data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

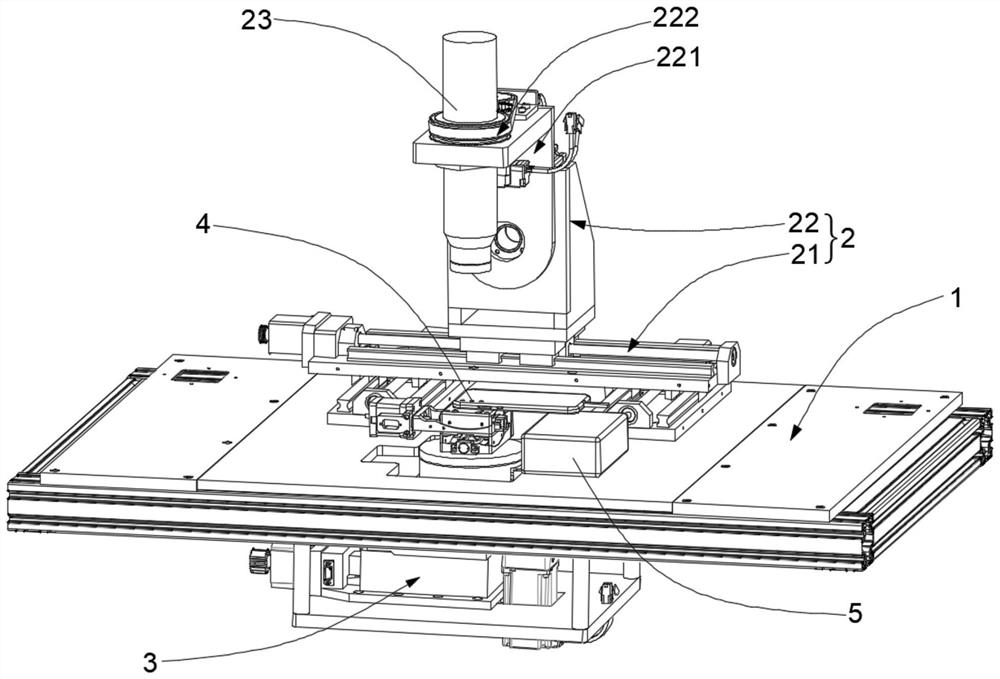

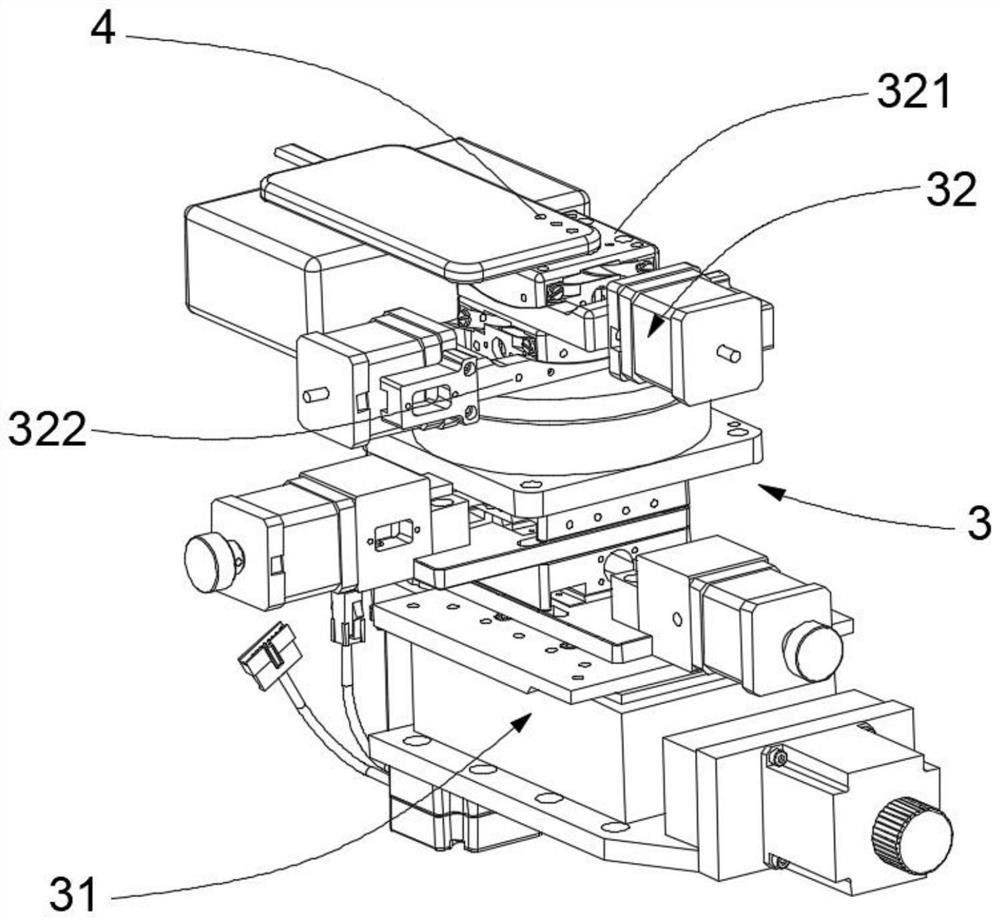

[0054] This embodiment provides a camera testing device, which can be used to test the imaging of the camera 4 .

[0055] Such as figure 1 As shown, the camera testing device includes a support platform 1 , a collimator 23 , a first adjustment module 2 , a second adjustment module 3 and an image receiving assembly 5 . The first adjustment module 2 includes an XY moving platform 21 arranged on the support platform 1 and a rotating module 22 arranged at the driving end of the XY moving platform 21. The XY moving platform 21 can be used to adjust the position of the rotating module 22 in the horizontal plane. At the same time, the driving end of the rotating module 22 is connected to the collimator 23 , and the position of the collimator 23 in the horizontal plane can be adjusted through the XY moving platform 21 to facilitate the subsequent detection of the imaging of the camera 4 . Wherein, the collimator 23 includes a collimator body, a map card and a light source assembly, a...

Embodiment 2

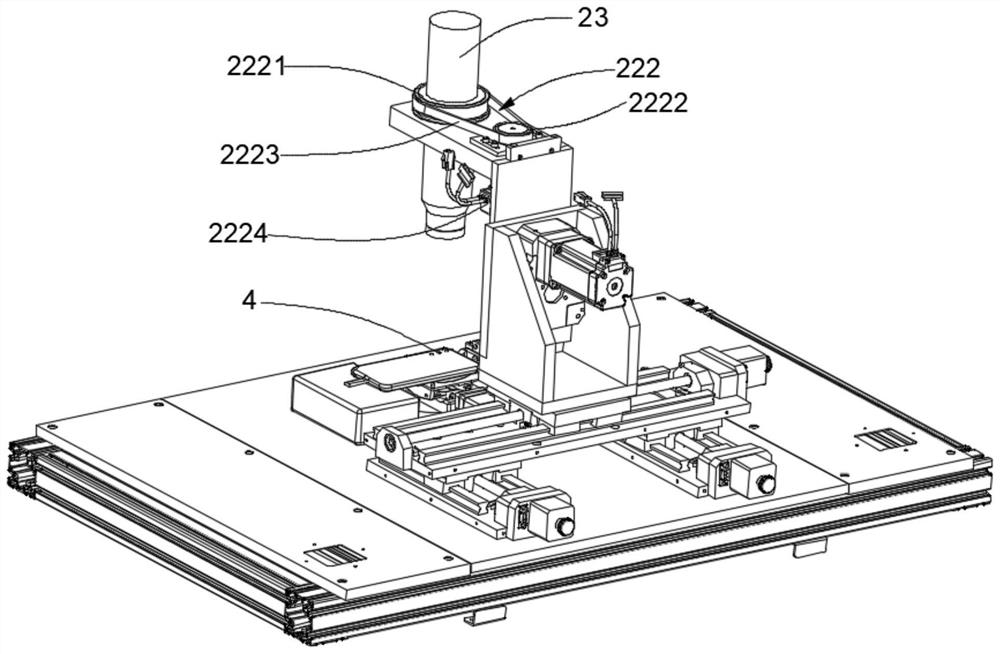

[0075] This embodiment also provides a camera testing device, which can also be used to test the imaging of the camera 4 .

[0076] The camera testing equipment provided in this embodiment is basically the same as the camera testing equipment in Embodiment 1, the difference is that in this embodiment, the carrying assembly 221 includes a moving frame 2211 , a swinging frame 2212 and a second rotating drive assembly 2213 . Such as Figure 4~5 As shown, the moving frame 2211 is arranged on the driving end of the XY moving platform 21, the second rotating drive assembly 2213 is arranged on the moving frame 2211, and the output end of the second rotating driving assembly 2213 is fixedly connected to the swing frame 2212 for driving the swing The frame 2212 swings in the vertical plane. At the same time, the collimator 23 and the first rotating drive assembly 222 are arranged on the swing frame 2212, so that the collimator 23 is also vertically rotated by the swing frame 2212 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com