A precise time-delayed hole-by-hole vertical undercut blasting method for large-diameter double-hole charge in rock roadway

A large-diameter, double-hole technology, which is used in blasting, earth-moving drilling, ground mining, etc., can solve the problems of not giving full play to the role of large-diameter holes, and the hole layout method cannot meet the cycle footage, and achieve good cutting and blasting. effect, increase the utilization rate of blast holes, and reduce the effect of clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: a kind of rock roadway large-diameter double-hole charge accurate time-delayed hole-by-hole vertical undercut blasting method, concrete steps are as follows:

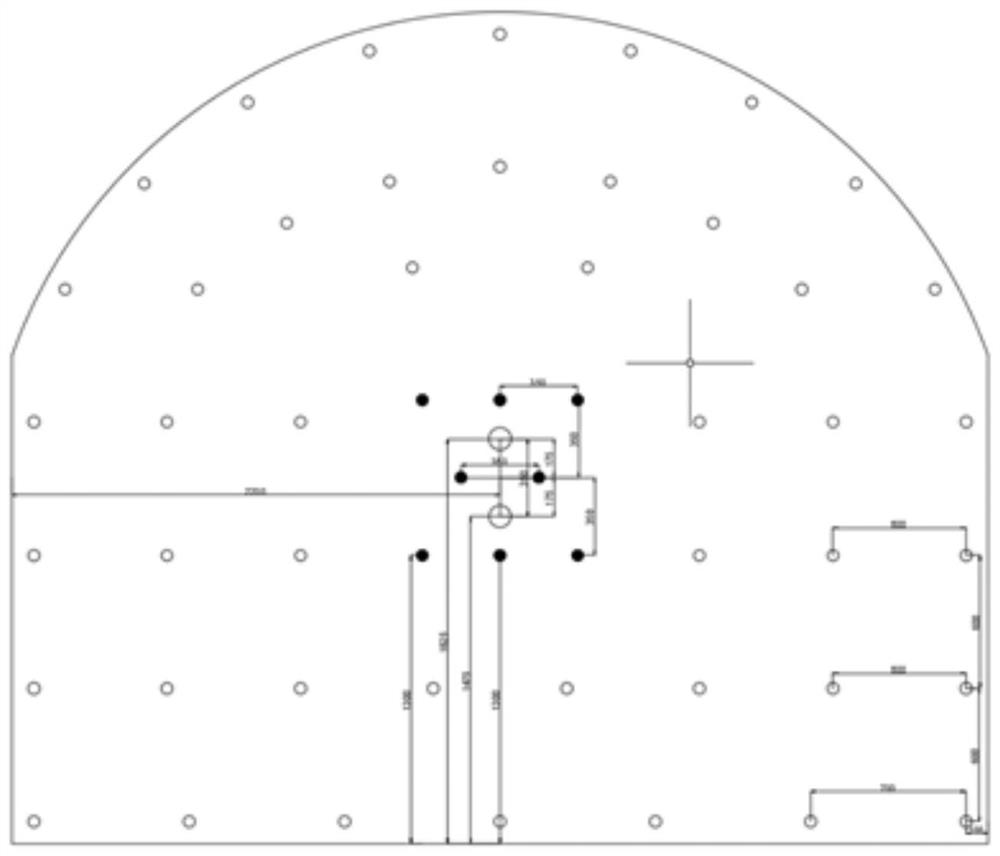

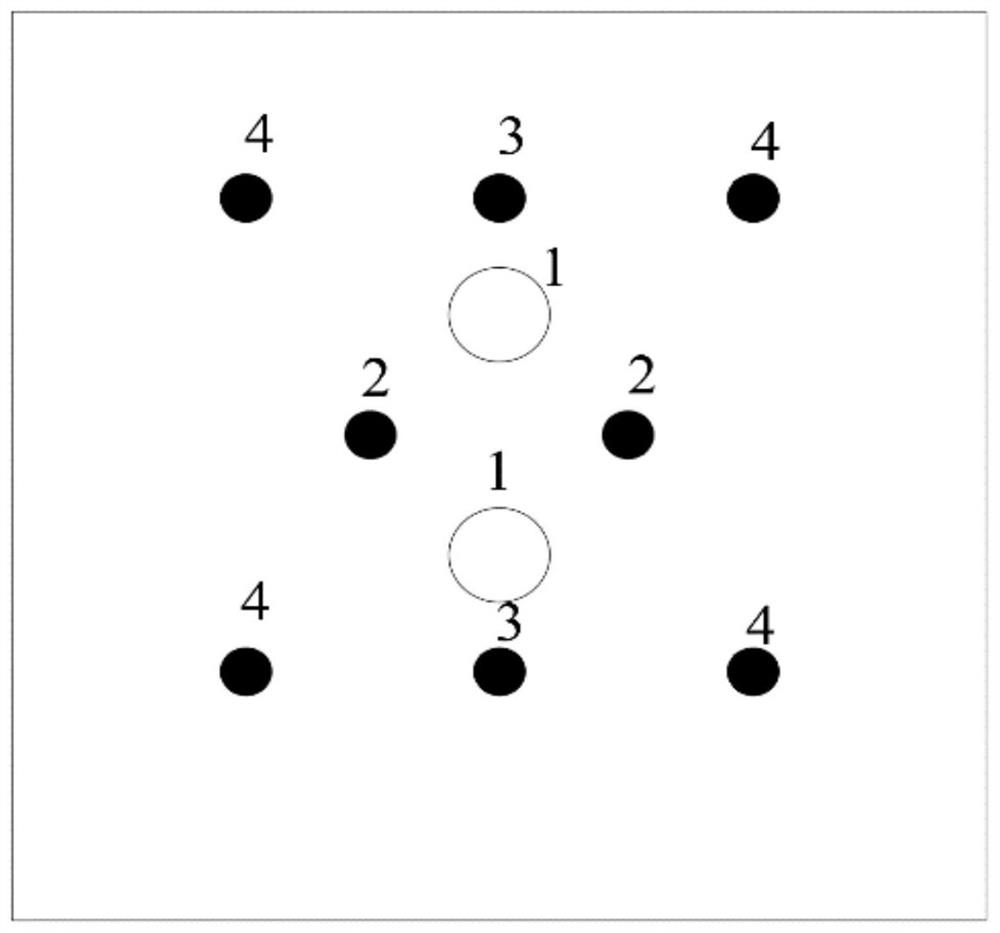

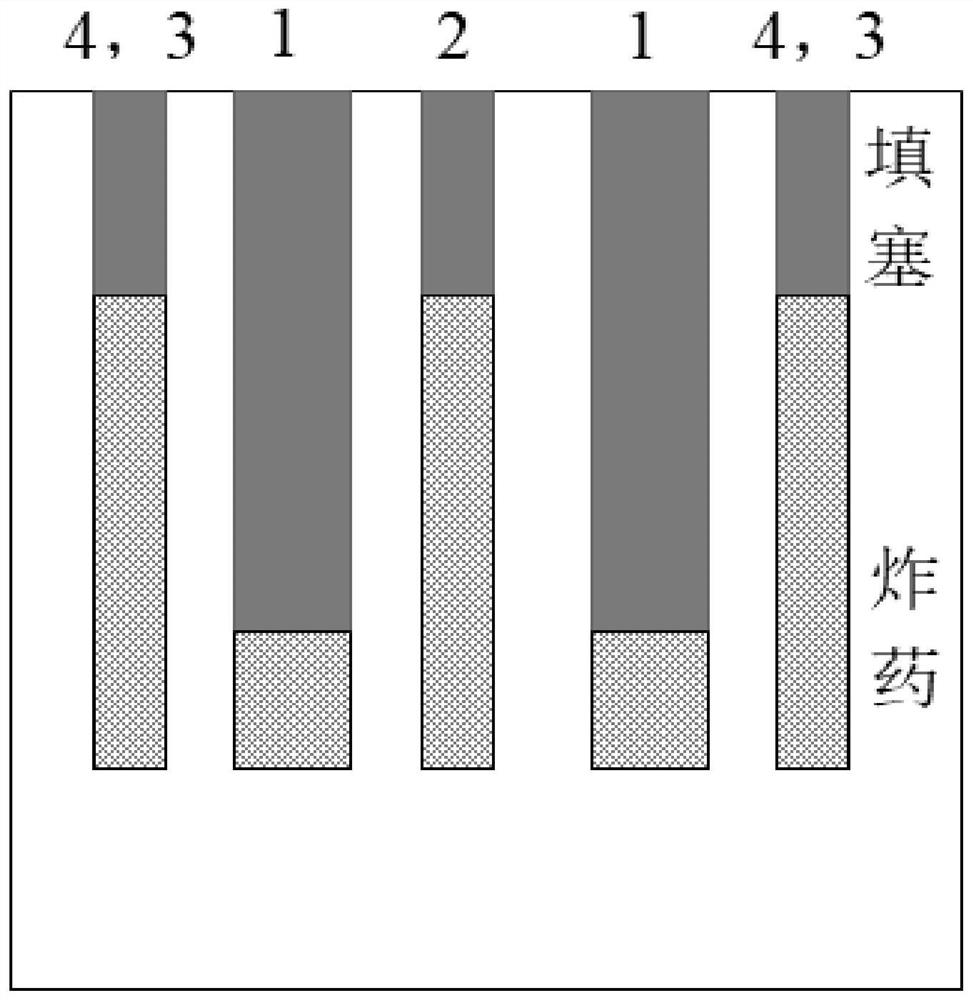

[0044] (1) According to the excavation section, design and drill several main undercut holes and several auxiliary undercut holes (see figure 1 ); wherein the main undercut hole is located at the center of the excavation section, the row spacing of the main undercut hole is equal to the column spacing of the main undercut hole, the auxiliary undercut hole is located on the central axis of the adjacent row of the main undercut hole and the auxiliary undercut hole It is located on the central axis of the main undercut holes in adjacent rows; the diameter of the auxiliary undercut holes is larger than that of the main undercut holes, and the depth of the auxiliary undercut holes is the same as that of the main undercut holes;

[0045] The auxiliary cut hole spacing is determined by numerical simulation...

Embodiment 2

[0070] Example 2: Taking the vertical deep-hole excavation and blasting project in the middle section of the roadway of Yuxi Mining Dahongshan Copper Mine 285 as an example, the cross-sectional size of the roadway is 4.4×3.7m 2

[0071] A method for accurate time-delayed hole-by-hole vertical undercut blasting with large-diameter double-hole charge in rock roadway, the specific steps are as follows:

[0072]

[0073] (1) According to the excavation section, design and drill several main undercut holes and several auxiliary undercut holes (see figure 1 and figure 2 ); wherein the main undercut hole is located at the center of the excavation section, the row spacing of the main undercut hole is equal to the column spacing of the main undercut hole, the auxiliary undercut hole is located on the central axis of the adjacent row of the main undercut hole and the auxiliary undercut hole It is located on the central axis of the main undercut holes in adjacent rows; the diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com