Sludge digestion tank

A digestion tank and sludge technology, applied in biological sludge treatment, chemical instruments and methods, dissolution, etc., can solve problems such as easy accumulation of sludge, poor stirring function of sludge digestion tank, and inability to stir sludge at the bottom. Achieve the effect of improving the stirring effect and reducing the stirring pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

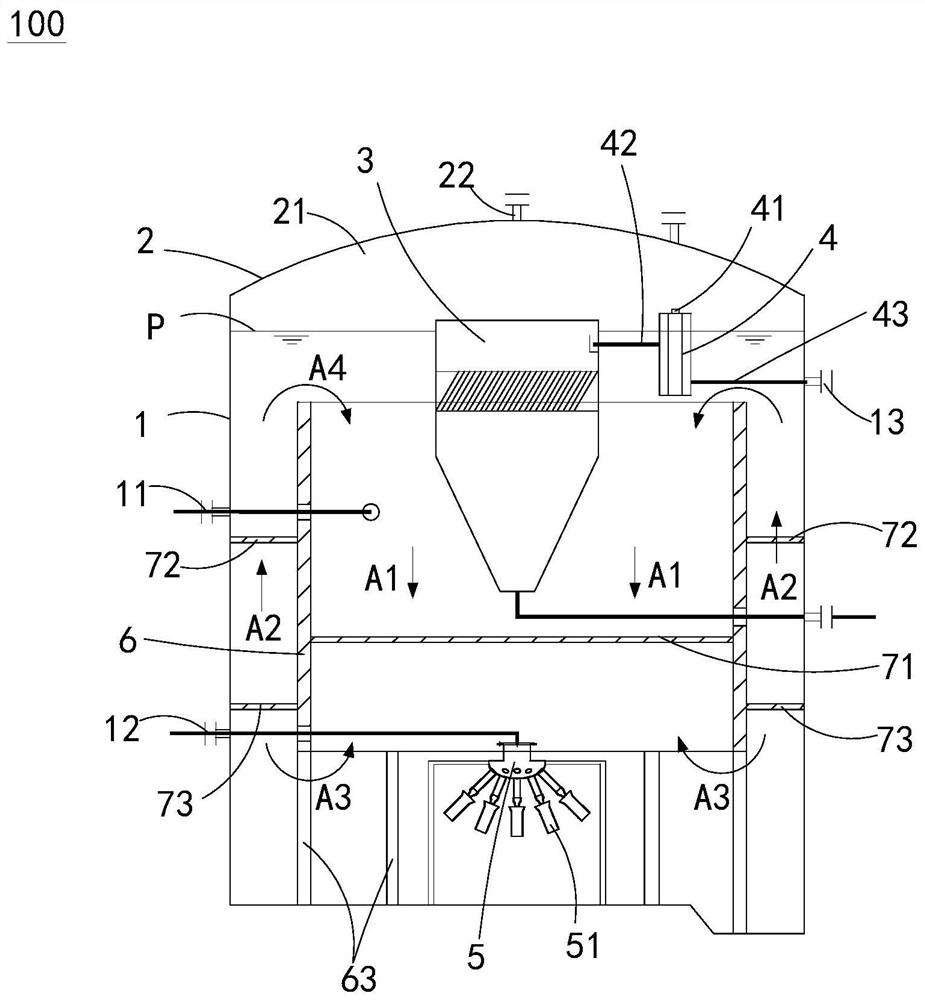

[0023] The embodiment of the present invention provides a sludge digestion tank, which can stir the sludge at the bottom, and can prevent the sludge from accumulating in dead corners of the tank, thereby greatly improving the stirring function.

[0024] The technical solution in the embodiments of the present invention is to solve the above-mentioned problems, and the general idea is as follows: the sludge digestion tank of the present invention sprays water obliquely downwards from the nozzle of the jet agitator, which can impact the dead corners at the bottom of the tank body and avoid pooling at the dead corners. The sludge greatly improves the mixing effect; the tank is equipped with a circulating inner cylinder to separate the space in the tank into multiple areas. After the sludge enters the circulating inner cylinder, it diffuses to the outside of the circulating inner cylinder under the action of the jet agitator, and then It rises from between the circulation inner cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com