Industrial automatic round log grinding equipment

An industrial round log technology, which is applied in the field of automatic grinding equipment for industrial round logs, can solve the problems of affecting efficiency, staff fatigue, and consuming a lot of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

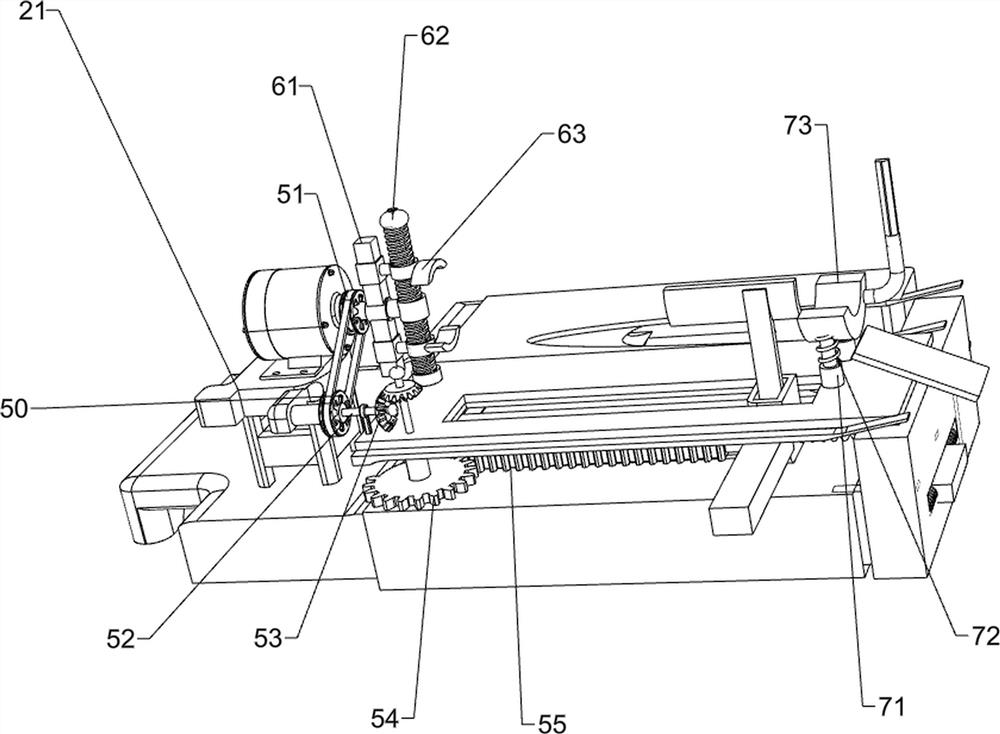

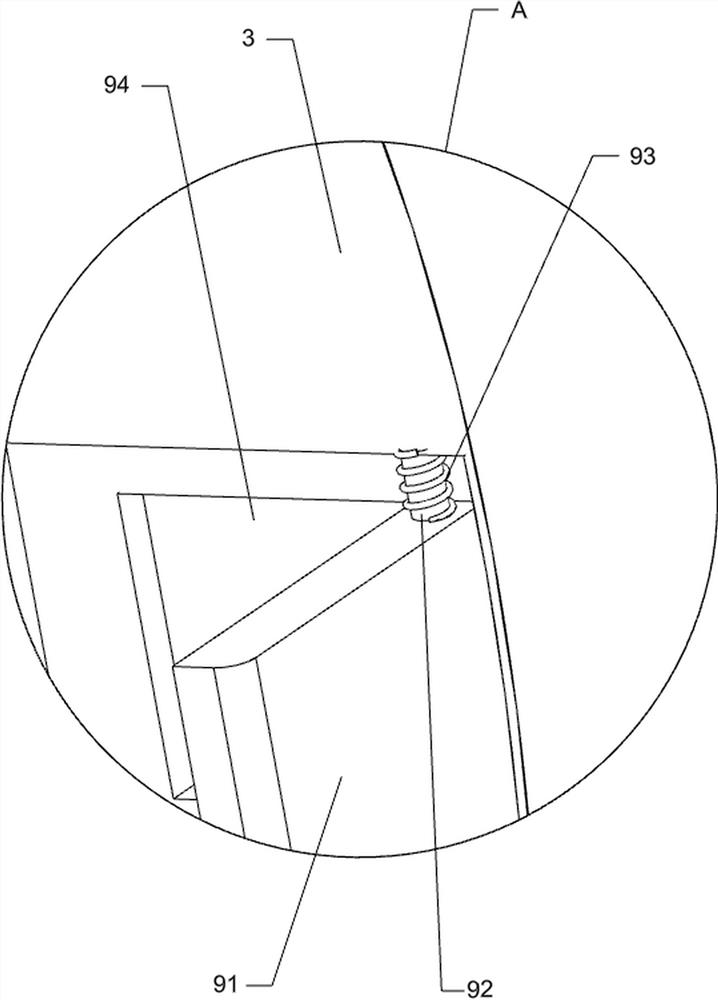

[0024] A kind of automatic grinding equipment for industrial logs, such as Figure 1-3 As shown, it includes a base 1, a mounting base 21, a motor 2, a grinding plate 3, a first spring 4, a moving mechanism 5 and a clamping mechanism 6, a mounting base 21 is provided on the left front side of the top of the base 1, and a mounting base 21 is provided on the mounting base 21. A moving mechanism 5 is connected between the motor 2, the base 1, the mounting seat 21 and the output shaft of the motor 2, the moving mechanism 5 is connected with a grinding plate 3, the first spring 4 is connected between the right side of the grinding plate 3 and the base 1, and the motor 2 The output shaft is connected with a clamping mechanism 6 .

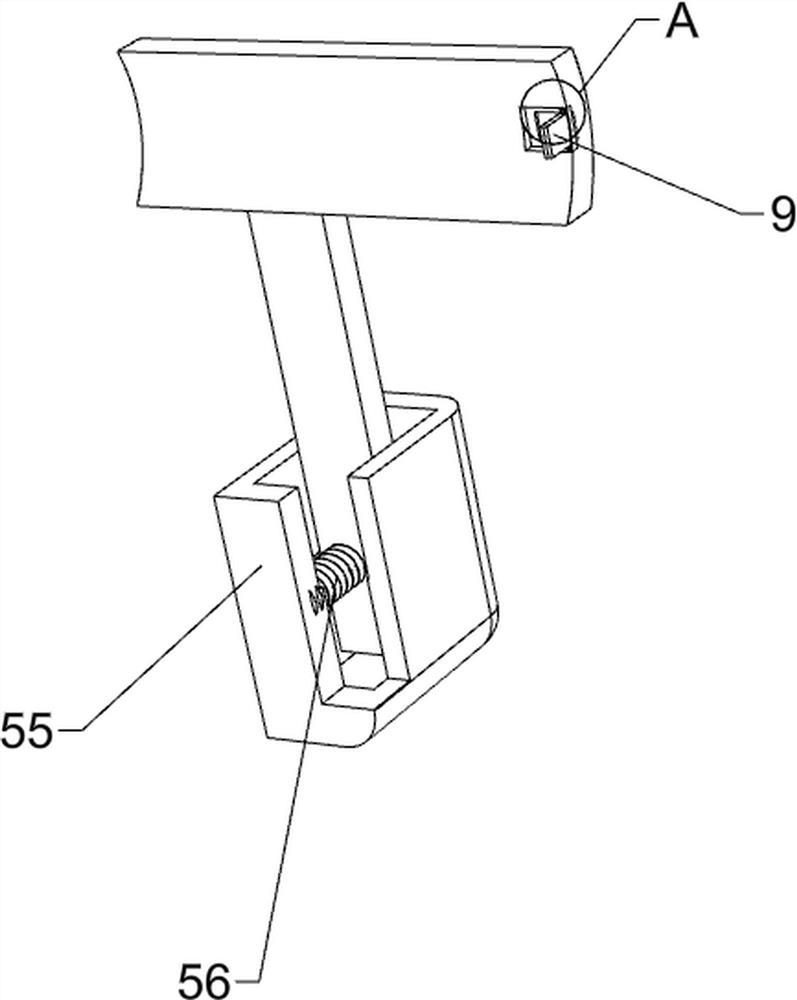

[0025] The moving mechanism 5 includes a transmission wheel 50, a belt 51, a rotating shaft 52, a bevel gear 53, a missing gear 54, a first rack 55 and a second spring 56, and a rotating shaft 52 is rotationally connected between the right front side of t...

Embodiment 2

[0029] On the basis of Example 1, such as figure 1 , figure 2 , Figure 4 , Figure 5 with Image 6 As shown, a support mechanism 7 is also included. The support mechanism 7 includes a telescopic rod 71, a third spring 72 and a support plate 73. Two telescopic rods 71 are arranged on the right side of the top of the base 1, and a support is connected between the tops of the telescopic rods 71. A third spring 72 is arranged between the plate 73 , the front and rear sides of the bottom of the support plate 73 and the bottom of the telescopic rod 71 .

[0030] After people place the log on the support plate 73, due to gravity, the support plate 73 moves downward, so that the telescopic rod 71 and the third spring 72 are compressed, so that the log can be supported and buffered, and the log can be removed. Finally, under the action of the third spring 72, the telescopic rod 71 is driven to stretch and reset, and the supporting plate 73 is driven to move upward and reset.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com