Portable flame cutting device for H-shaped steel

A flame cutting, H-beam technology, applied in gas flame welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of complicated adjustment of the position of the end, reduce the site utilization rate, single process congestion, etc., to improve production efficiency and The utilization rate of the site, the effect of reducing the risk probability and safety accident coefficient, and reducing the number of turns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

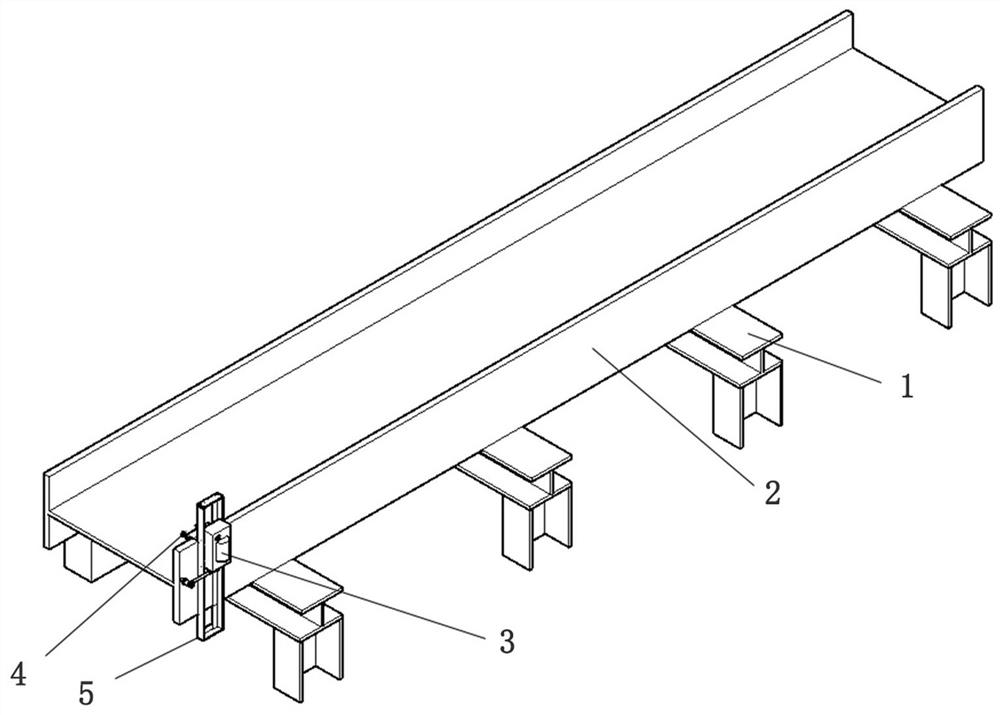

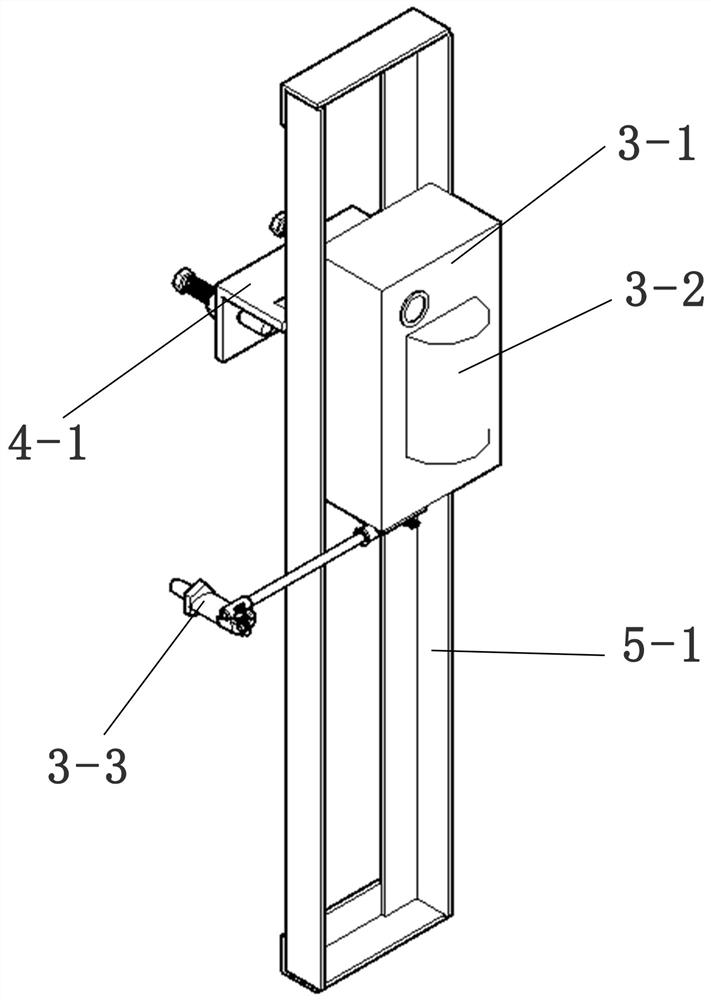

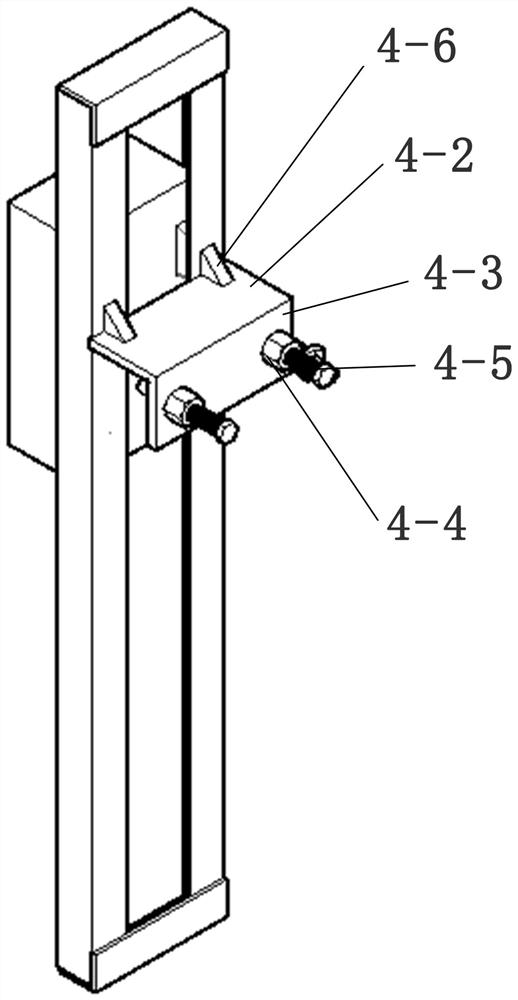

[0030] like Figure 1-3 As shown, a convenient flame cutting device for H-beam 2 includes stirrup 1, H-beam 2 and a pipe climbing machine 3, the stirrup 1 is located below the H-beam 2, and the pipe-climbing machine 3 is located on the H-beam 2; the described The web of the H-shaped steel 2 is arranged horizontally, and the lower end of the flange plate of the H-shaped steel 2 is in contact with the stirrup 1; the H-shaped steel 2 is also connected to the clamp 4 and the rail 5, and the clamp 4 and the rail 5 are sleeved on the H-shaped steel 2. and the rail 5 is located on the outer side of the flange board, and the clamp 4 is located on the inner side of the flange board; the pipe climbing machine 3 is located in the rail 5, and the rail 5 is vertically arranged along the width direction of the flange board.

[0031] The stirrup 1 is used to set t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com