Cleaning equipment for automobile tire

A technology for cleaning equipment and automobile tires, which is applied in the direction of cleaning methods using liquids, cleaning methods using tools, cleaning methods and utensils, etc. It can solve the problems of inability to recycle water resources, need to clean regularly, and easy to block the filter screen, etc. problems, to achieve the effect of increasing the scope of spraying, saving manpower, and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

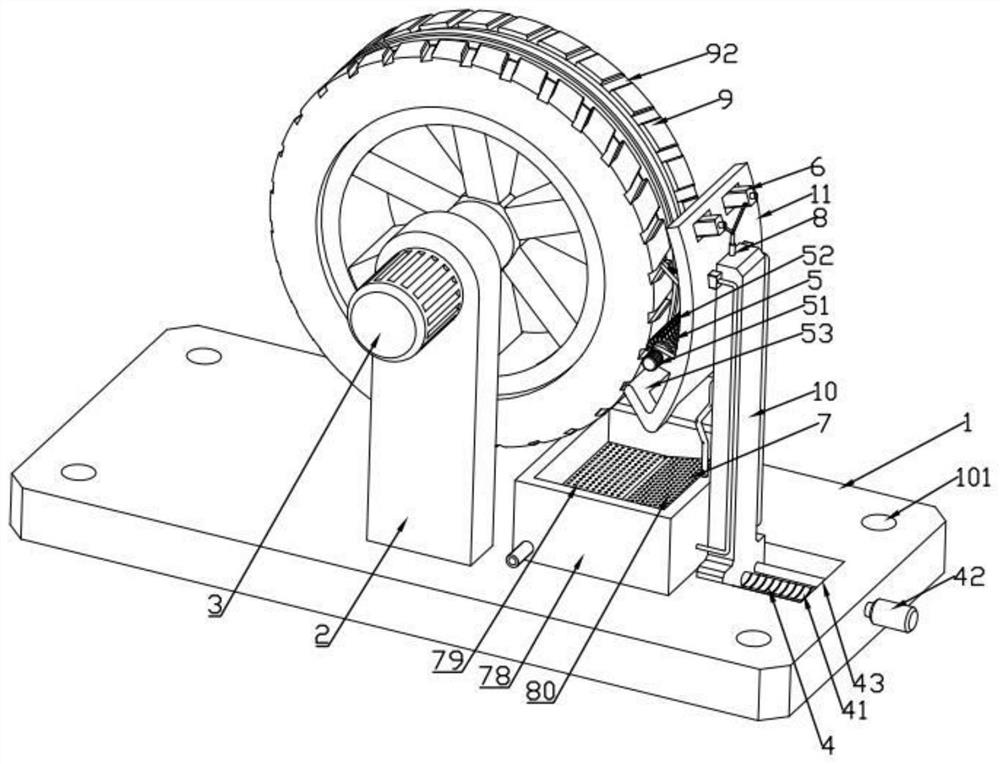

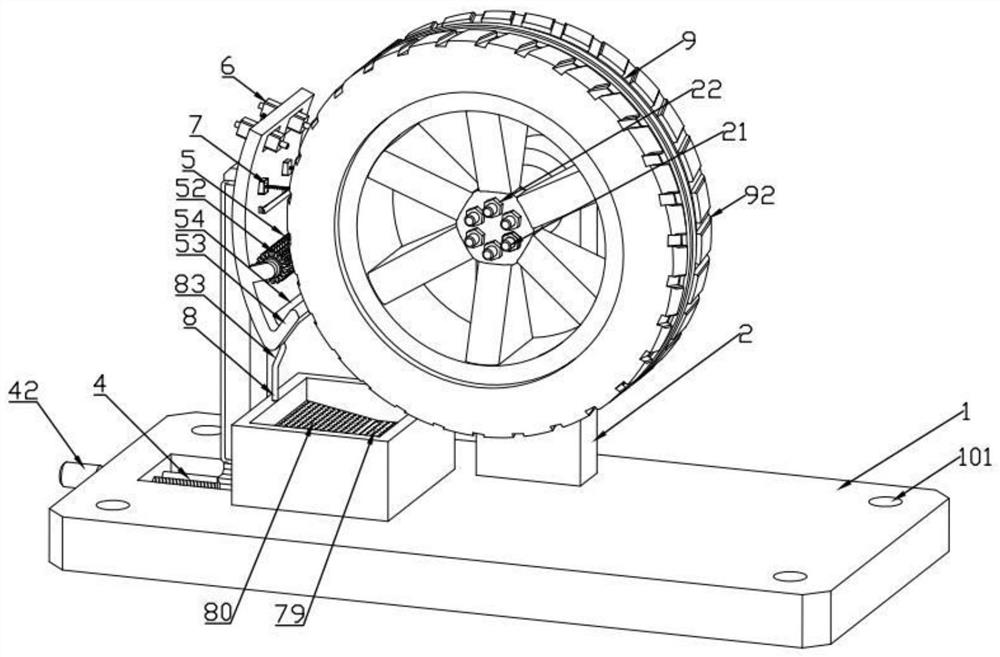

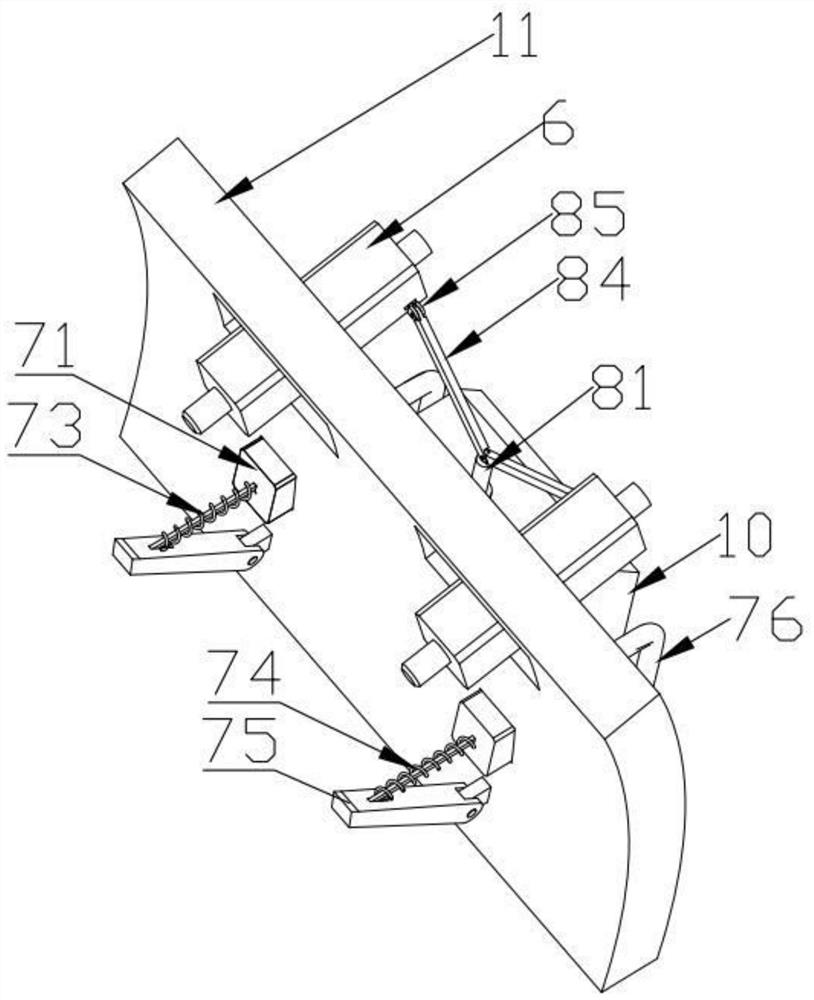

[0022] Such as Figure 1 to Figure 8 As shown, a cleaning device for automobile tires includes a base 1 on which a vertical block 2 is installed. The base 1 is provided with a mounting hole 101 to facilitate the installation of the base 1. The vertical block 2 is rotatably connected There is a rotating block for installing the tire 9. The rotating block is provided with a mounting bolt 21 that is compatible with the tire 9 jack 91. The mounting bolt 21 is threaded with a nut 22. Through the mounting bolt 21, it is convenient to install the tire. 9 plays a positioning role, and the mounting bolts 21 cooperate with the nuts 22 to realize the fixing of the tire 9. The vertical block 2 is provided with a driving motor 3 that drives the rotating block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com