A light-colored catechol lignosulfonate sunscreen microcapsules and its preparation and application

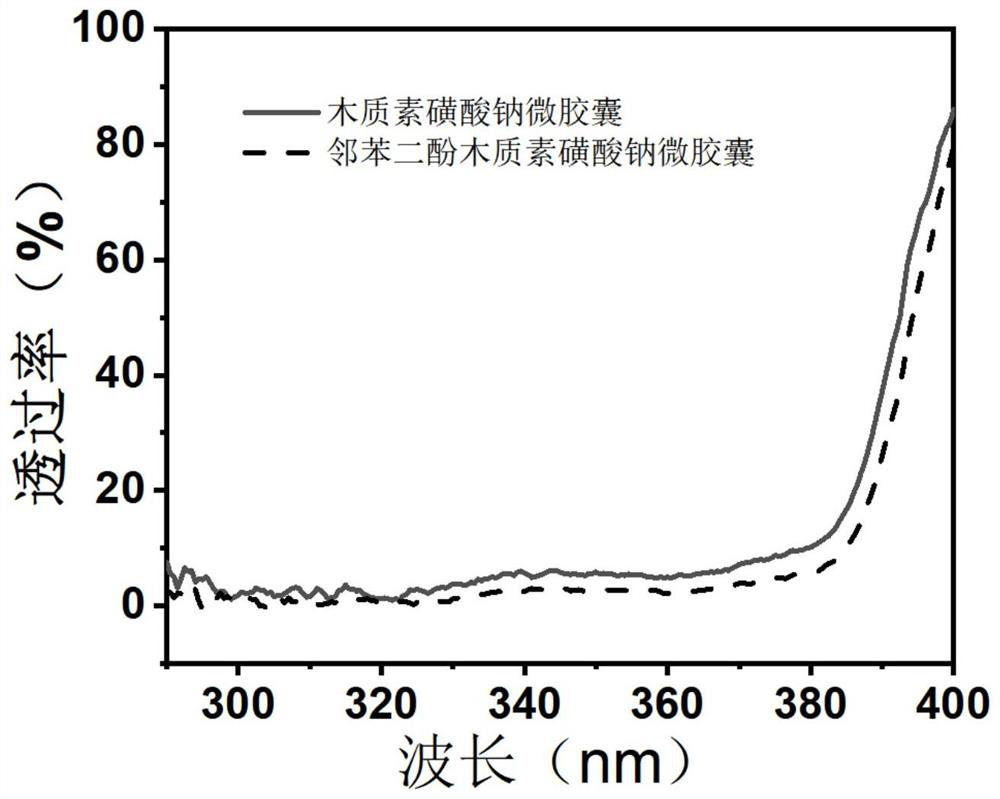

A technology of lignosulfonate and catechol, applied in the field of fine chemicals, can solve the problems of poor free radical scavenging ability, limited application in the field of sunscreen, poor stability of sunscreen agents, etc., and achieves good biocompatibility, Improve the anti-photolysis performance and solve the effect of poor water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) 10g of sodium lignosulfonate and 1.5g of sodium sulfite dissolved in 30ml, 10wt% NaOH solution, 90 °C for condensation reflux reaction for 1 hour, cooled to room temperature after the end of the reaction, the reaction liquid in pure water for dialysis purification treatment, after dialysis the sample solution was concentrated and dried to obtain a phthalol lignosulfonate solid powder.

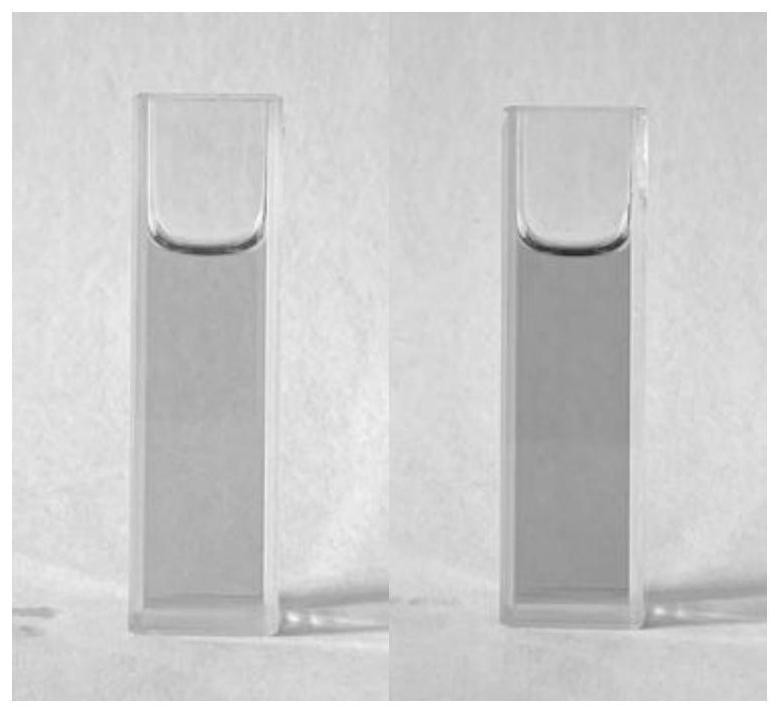

[0053](2) 0.21g of catechol lignosulfonate dissolved in 6.79g of ultrapure water, prepared to obtain a solution of 5wt%, added 3g of ethylhexyl methoxycinnamate and avobenzone (mass ratio of 4:1) mixture and 0.7g Tween, ultrasonic cavitation of 400W state for 3min, to obtain a bioadhesive microencapsulant emulsion of catechol lignosulfonate / chemical sunscreen, 10000r / min centrifugation for 30min, to obtain phthalcinol lignosulfonate / Bioadhesive microcapsules of chemical sunscreens. The microcapsules were mixed with blank creams without sunscreen active ingredients (Nivea Deep Moist...

Embodiment 2

[0060] (1) 10g of magnesium lignosulfonate and 2g of sodium sulfite were dissolved in 30mL of 15wt% NaOH solution, condensed reflux reaction at 120 °C for 1 hour, cooled to room temperature after the end of the reaction, the reaction liquid was purified by dialysis in pure water, and the sample solution was concentrated and dried after dialysis to obtain a solid calcium of catechol lignosulfonate.

[0061](2) 0.21g of catechol lignosulfonate dissolved in 6.79g of ultrapure water, prepared to obtain a solution of 3wt%, added 4g of humolefin and avobenzone (mass ratio of 4:1) mixture and 1g Tween, ultrasonic cavitation of 5min in the state of ultrasonic power of 600W, centrifugation of 30min, 8000r / min to obtain a bioadhesive microcapsules of phthalcin lignosulfonate / chemical sunscreen. The microcapsules were mixed with blank creams without sunscreen active ingredients (Nivea Deep Moisturizing Hand Cream, Nivea (Shanghai) Co., Ltd.) to produce a bio-adhering microcapsule of catech...

Embodiment 3

[0064] (1) 10g of sodium lignosulfonate and 0.7g of sodium metabisulfite were dissolved in 40mL of 5wt% NaOH solution, condensed reflux reaction at 70 °C for 2.5 hours, cooled to room temperature after the reaction, the reaction liquid was purified in pure water for dialysis, and the sample solution was concentrated and dried after dialysis to obtain a solid calcium of lignosulfonate.

[0065] (2) 0.6g of catechol lignosulfonate dissolved in 6.4g of ultrapure water, prepared to obtain a solution of 3wt%, added 3g of ethylhexyl methoxycinnamate and avobenzone (mass ratio of 4:1) mixture and 0.3g of sucrose ester, ultrasonic cavitation of 3min in the state of ultrasonic power of 400W, centrifugation of 5000r / min for 40min, to obtain a bioadhesive microcapsules of catechol lignosulfonate / chemical sunscreen. The microcapsules were mixed with blank creams without sunscreen active ingredients (Nivea Deep Moisturizing Hand Cream, Nivea (Shanghai) Co., Ltd.) to produce a bio-adhering mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com