Gravity steel ball displacement type automatic energy storage power station and working method

An energy storage power station, displacement technology, applied in the direction of electric energy storage system, energy industry, electrical components, etc., can solve the problems of battery cell defects, waste of environmental resources, unreliable battery management system, etc., to achieve commercial value and social High value, wide site requirements, and the effect of automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

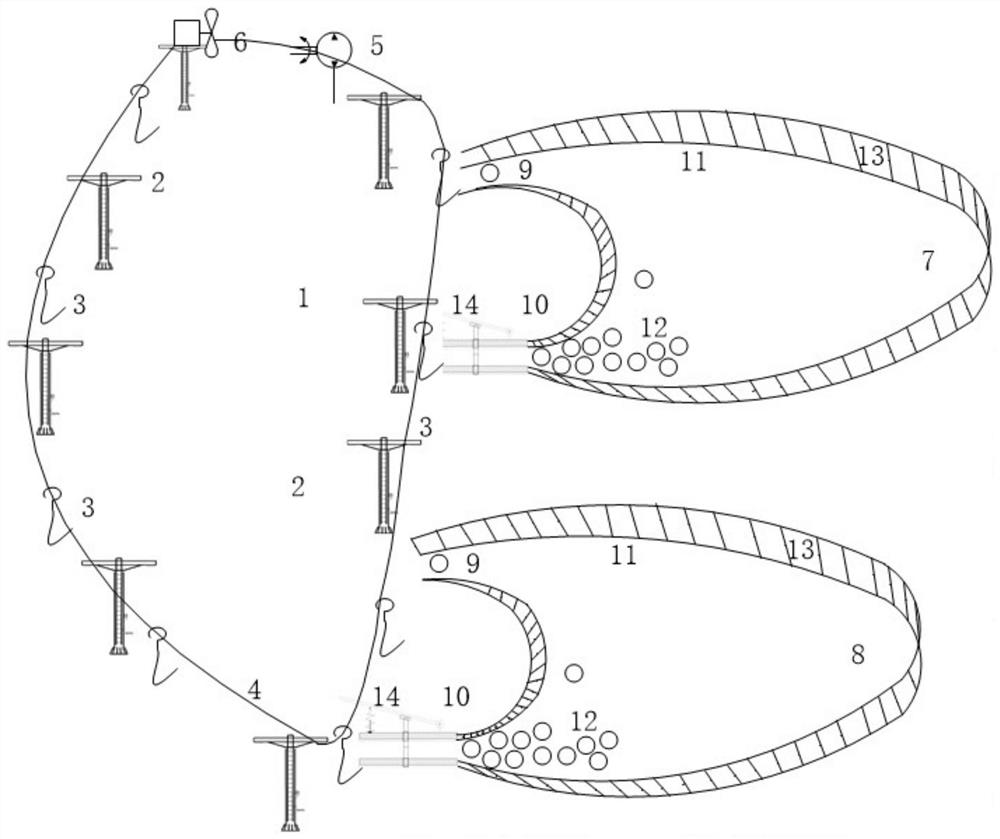

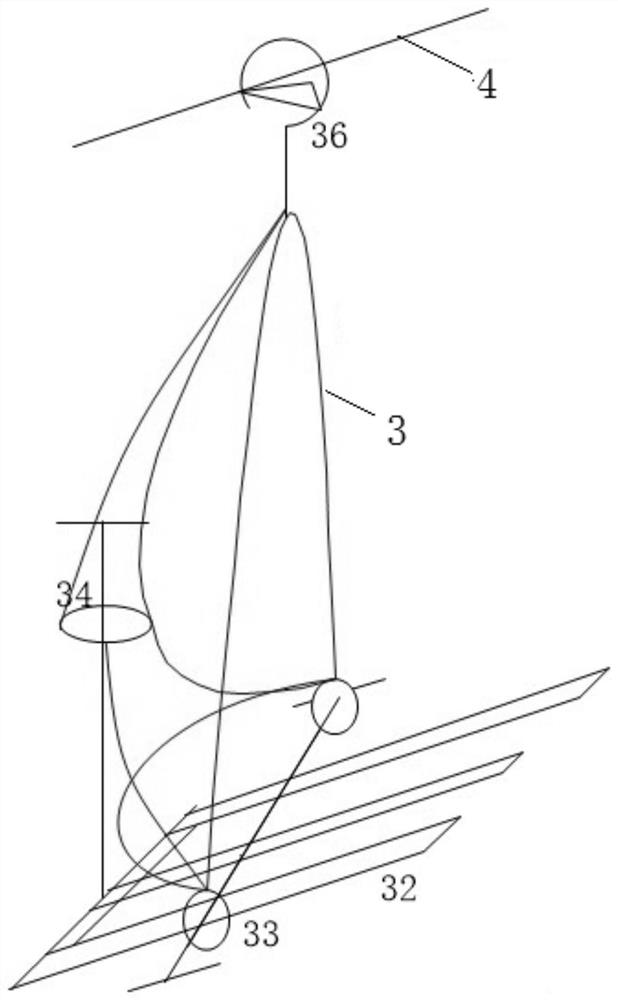

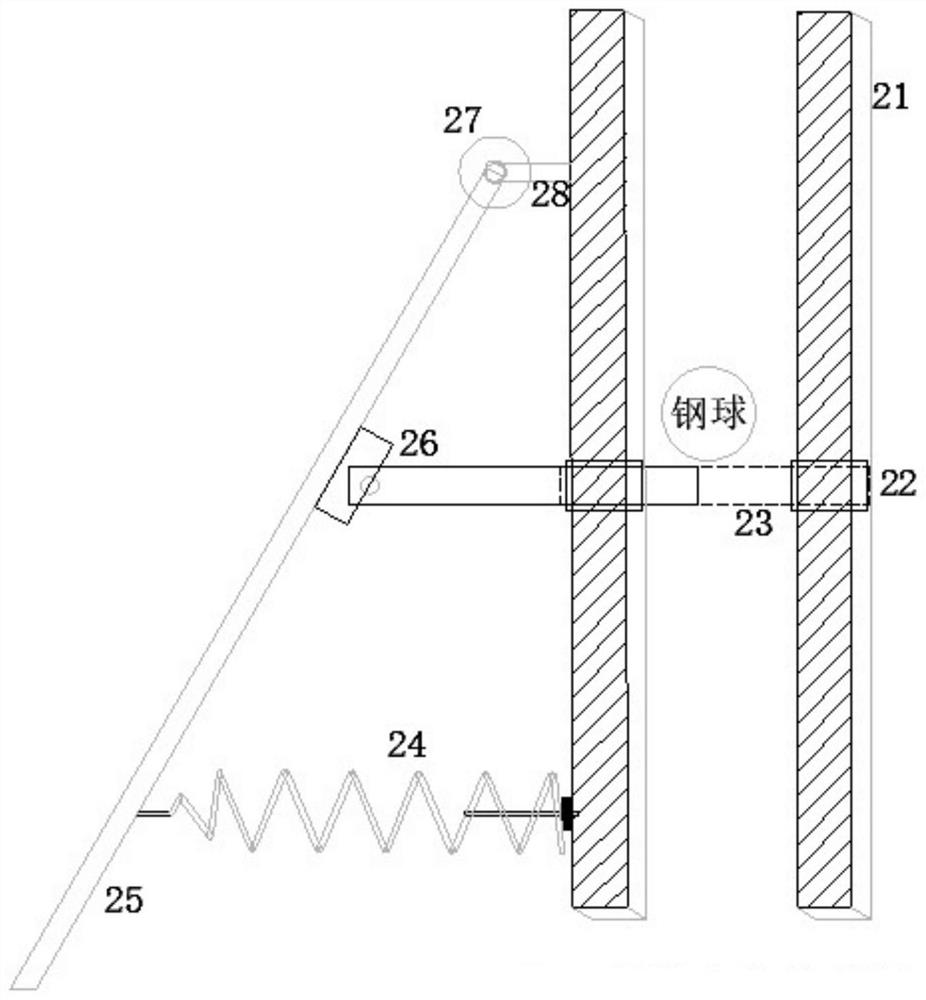

[0026] like figure 1 with Figure 4 As shown, the present invention is a gravity-displacement automatic energy storage power station, which includes a tower 2 built on a hillside 1, a load-bearing steel cable 4 on the tower 2, and a cable holder 36 fixed on the load-bearing steel cable 4. Ball lifting grid 3, the motor that drives the load-bearing steel cable 4 to move 5, the generator driven by the load-bearing steel cable 4 to generate electricity 6, the high-level storage court built at a high place 7, the low-level storage court for storing steel balls when the steel ball falls 8. Both the high storage court 7 and the low storage court 8 are equipped with a storage court unloading port 9 and a storage court lifting port 10. In order to realize the automatic delivery and homing of the gravity steel ball 12, the ground of the high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com