Electrical connector for circuit boards

A technology for circuit substrates and electrical connectors, which is applied to circuits, connections, and two-component connection devices, etc., can solve problems such as unsmooth assembly, uncertain position of the upper curved portion, and easy elastic deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

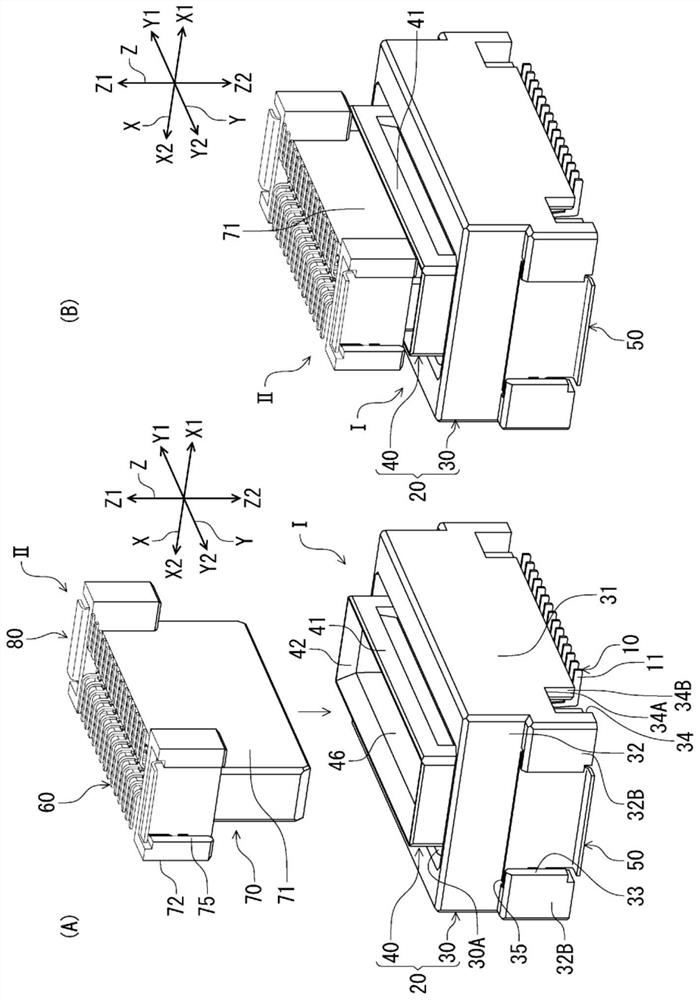

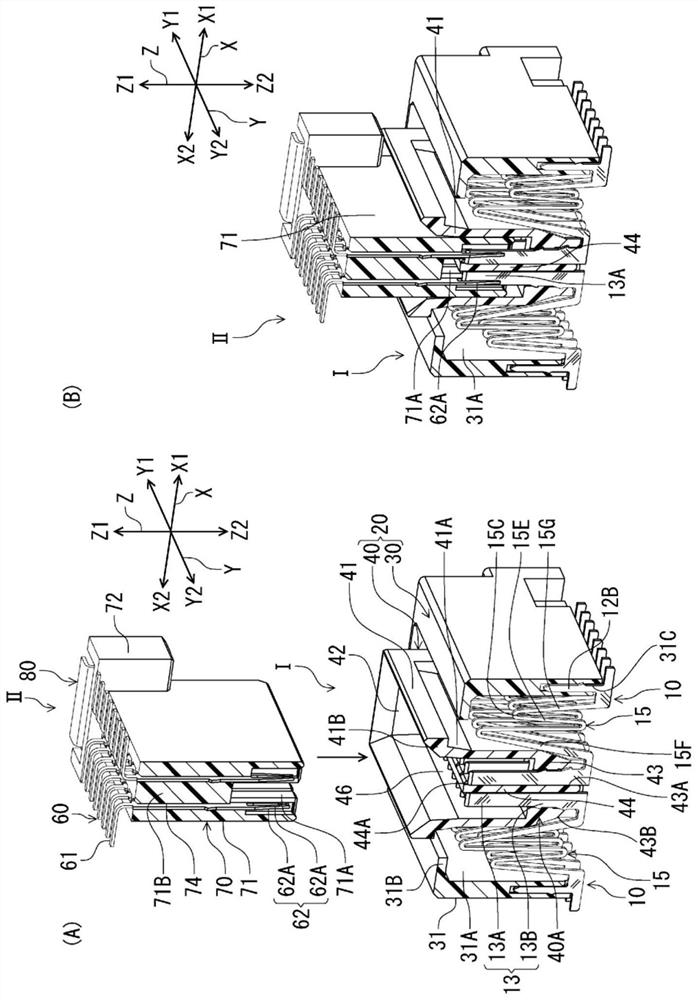

[0030] figure 1 (A), (B), figure 2The plug connector 1 according to this embodiment shown in (A) and (B) is an electrical connector for a circuit board mounted on a mounting surface of a circuit board (not shown). In addition, the receptacle connector II, which is a target connector (target connector) of the plug connector I, is an electrical connector for a circuit board mounted on a mounting surface of another circuit board (not shown). In each of the following figures showing this embodiment, in order to understand the directionality easily, the vertical direction at right angles to the mounting surface of the circuit board is set as the connector height direction Z, and the terminal arrangement direction in the connector is set as Let it be Y, and let X be the connector width direction which is the direction perpendicular|vertical to two directions of the connector height direction Z and the terminal arrangement direction Y. The plug connector I and the receptacle conne...

no. 2 approach >

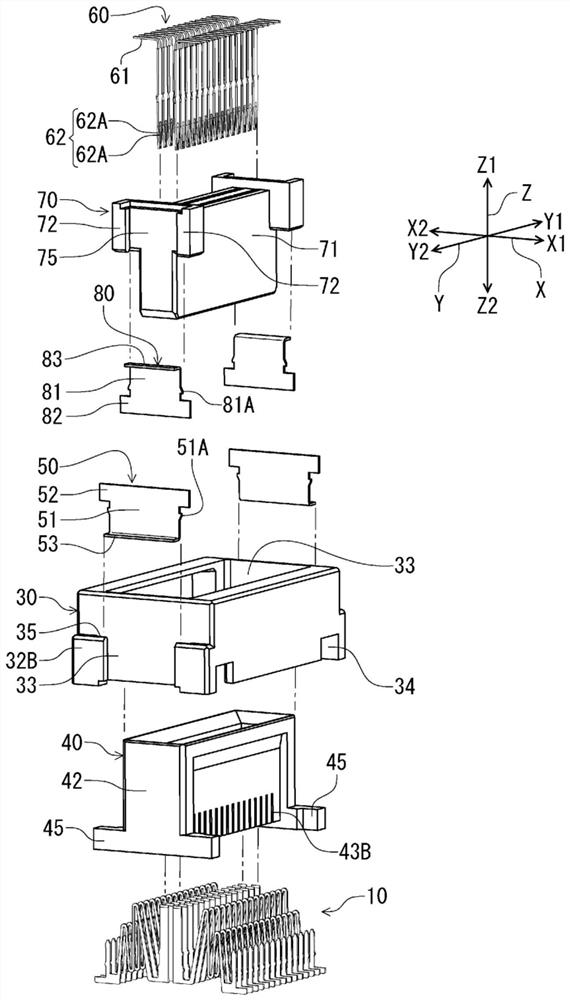

[0077] Figure 8 The second embodiment shown is different from the first embodiment in which the plug terminal is manufactured by punching a metal plate member in the thickness direction, and is characterized in that the plug terminal 110 is manufactured by bending a metal strip member in the thickness direction. The bottom surface side protrusion 143E formed on the bottom surface of the bottom wall 143 of the entrance wall portion 140A of the movable housing 140 protrudes downward from the plug terminal 110, and the rest is the same as that of the first embodiment, and corresponds to the first embodiment. The reference numerals added with "100" to the reference numerals in the first embodiment are assigned to the parts of , and redundant descriptions are omitted.

[0078] Such as Figure 8 As shown, the plug terminal 110 is a so-called bent terminal formed by bending a metal strip member in the thickness direction, and has a substantially M-shaped elastic portion 115 between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com