A tungsten hexafluoride liquid phase filling device

A technology of tungsten hexafluoride liquid and installation tank, which is applied to the installation device of container structure, container filling method, gas/liquid distribution and storage, etc., which can solve the problems of inability to reduce tungsten hexafluoride stimulation, inability to disperse and discharge container gas, Tungsten hexafluoride is harmful to the human body and other problems, and achieves the effect of good sealing, avoiding impact and reducing harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

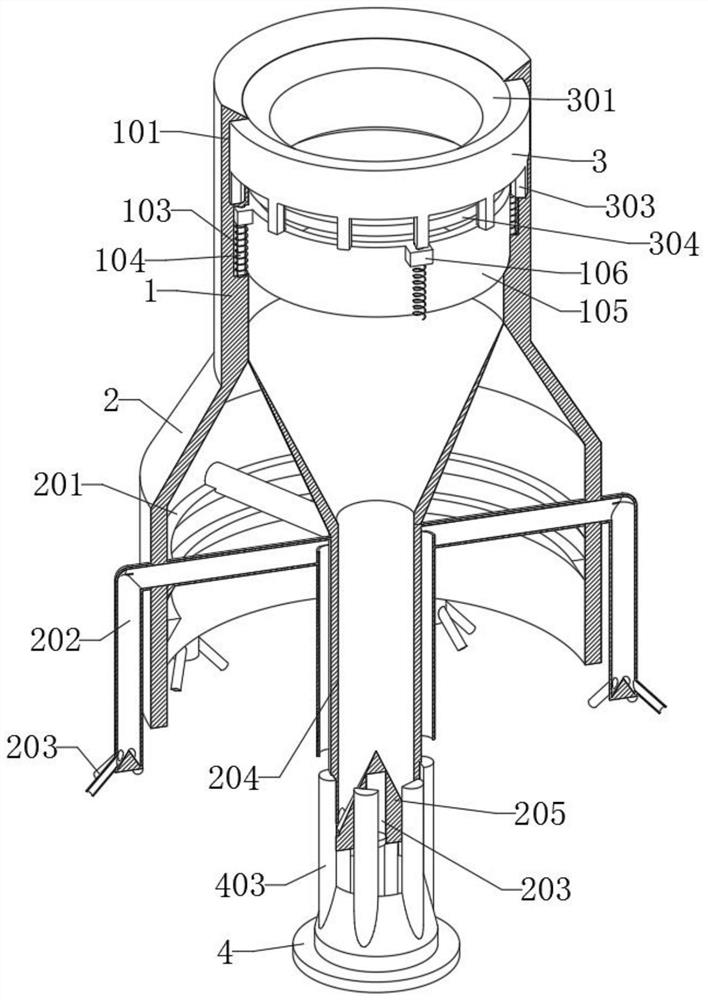

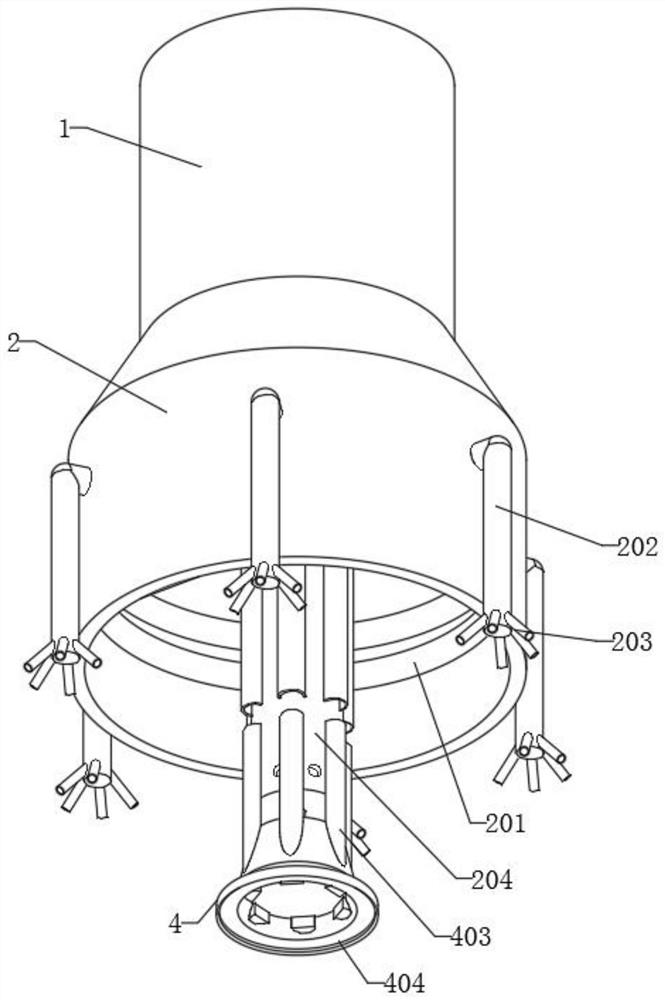

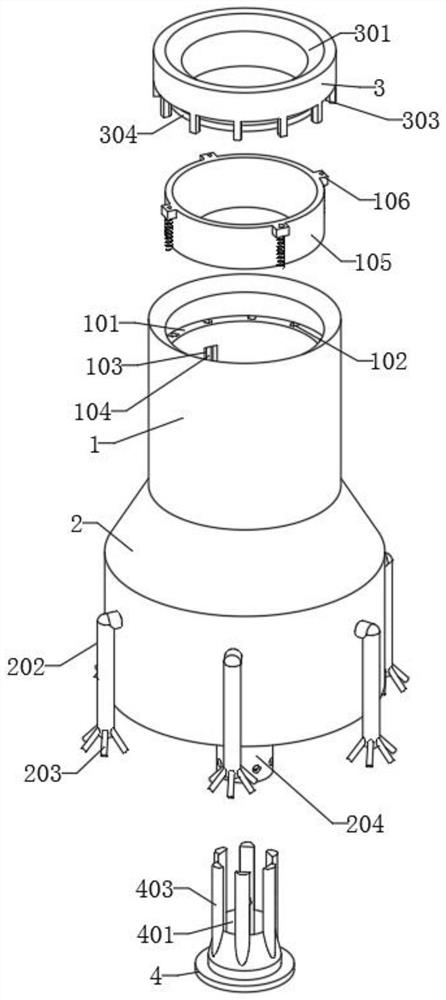

[0037] Such as Figure 1 to Figure 8 As shown, the present invention includes a main body container 1, a bottom part 2, an extrusion part 3 and a force-bearing part 4, the main body container 1 is a cylindrical tube, the bottom part 2 is fixedly connected to the bottom end of the main body container 1, and the The extrusion part 3 is installed in the main container 1 through the installation groove 101 and the slot 102, and the bottom part 2 is connected with the force-bearing part 4;

[0038] A ring-shaped moving part 105 is arranged in the main container 1, and four force bearing blocks 106 are uniformly arranged on the top of the outer wall of the moving part 105, and guide rods 104 are installed on the force bearing blocks 106;

[0039] The inner top of the bottom part 2 is trumpet-shaped, and the contact part 201 is arranged inside the bottom part 2. Six exhaust pipes 202 are uniformly arranged on the peripheral side of the bottom part 2, and the exhaust pipes 202 are U-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com