Preparation method of modified poly (vinylidene fluoride-co-hexafluoropropylene) grafted vinyl imidazole anion exchange membrane

A technology of anion exchange membrane and vinylidene fluoride, which is applied in anion exchange, ion exchange, chemical instruments and methods, etc., can solve the problems of conductivity and acid concentration performance, and achieve excellent acid concentration performance and low mass loss rate , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

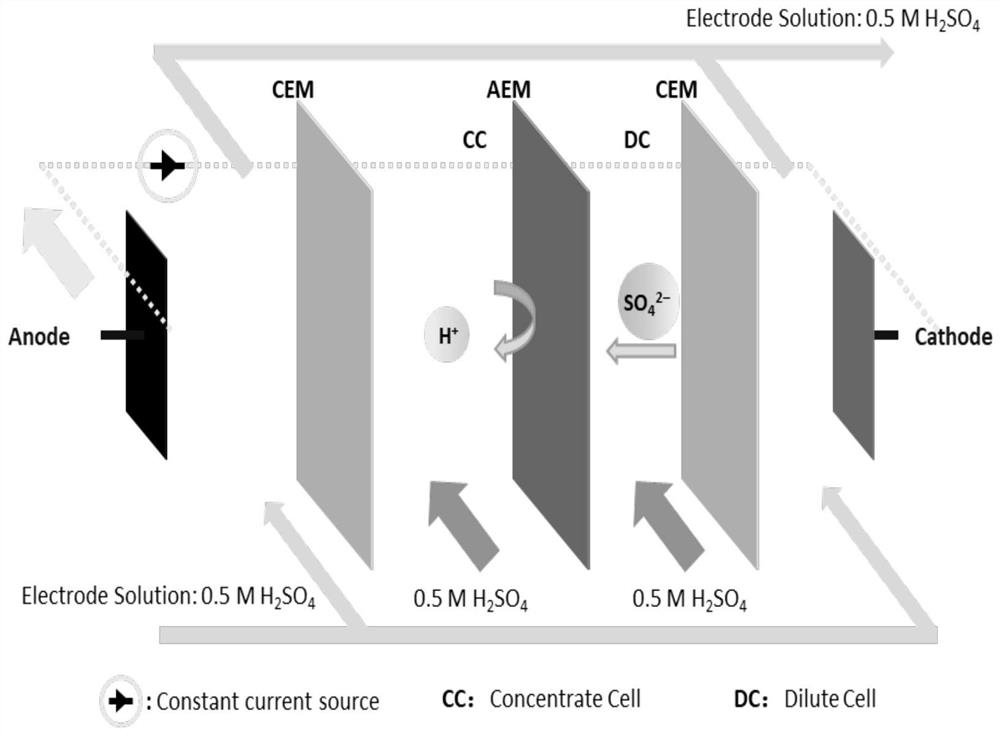

Image

Examples

Embodiment 1

[0027] (1) Weigh 20g of poly(vinylidene fluoride-co-hexafluoropropylene) in a single-necked flask, wherein each gram of poly(vinylidene fluoride-co-hexafluoropropylene) needs N,N-dimethylacetamide 15mL, stirred at room temperature for 10h to obtain a transparent solution A;

[0028] (2) According to the volume ratio of solution A and 0.15mol / L sodium hydroxide isopropanol solution is 10:1, measure 30mL volume of sodium hydroxide alcohol solution and slowly add it to 300mL solution A to prepare solution B. Stir magnetically at room temperature for 1 h to obtain solution C;

[0029] (3) Slowly add solution C to excess deionized water to obtain a brown-red fibrous solid. The above solid was washed with deionized water until neutral, and dried in vacuum at 80°C for 24 hours to obtain solid D;

[0030] (4) Weigh 6g of solid D, 2g of vinylimidazole liquid, and 0.12g of benzoyl peroxide, and dissolve them in 120mL of N-methylpyrrolidone to obtain solution E;

[0031] (5) Heat the ...

Embodiment 2

[0033] (1) Weigh 10g of poly(vinylidene fluoride-co-hexafluoropropylene) in a single-necked flask, wherein each gram of poly(vinylidene fluoride-co-hexafluoropropylene) needs N,N-dimethylacetamide 15mL, stirred at room temperature for 10h to obtain a transparent solution A;

[0034] (2) According to the volume ratio of solution A and 0.15mol / L sodium hydroxide isopropanol solution is 10:1, measure 15mL volume of sodium hydroxide alcohol solution and slowly add it to 150mL solution A to prepare solution B. Stir magnetically at room temperature for 1.5 h to obtain solution C;

[0035] (3) Slowly add solution C to excess deionized water to obtain a brown-red fibrous solid. The above solid was washed with deionized water until neutral, and dried in vacuum at 80°C for 24 hours to obtain solid D;

[0036] (4) Weigh 3g of solid D, 1.5g of vinylimidazole liquid, and 0.03g of benzoyl peroxide, and dissolve them in 60mL of N-methylpyrrolidone to obtain solution E;

[0037] (5) Heat t...

Embodiment 3

[0039] (1) Weigh 10g of poly(vinylidene fluoride-co-hexafluoropropylene) in a single-necked flask, wherein each gram of poly(vinylidene fluoride-co-hexafluoropropylene) needs N,N-dimethylacetamide 15mL, stirred at room temperature for 10h to obtain a transparent solution A;

[0040] (2) According to the volume ratio of solution A and 0.15mol / L sodium hydroxide isopropanol solution of 10:1, take 10mL volume of sodium hydroxide alcohol solution and slowly add it to 150mL solution A to prepare solution B. Stir magnetically at room temperature for 2 h to obtain solution C;

[0041](3) Slowly add solution C to excess deionized water to obtain a brown-red fibrous solid. The above solid was washed with deionized water until neutral, and dried in vacuum at 80°C for 24 hours to obtain solid D;

[0042] (4) Weigh 4.5g of solid D, 2g of vinylimidazole liquid, and 0.09g of benzoyl peroxide, and dissolve them in 90mL of N-methylpyrrolidone to obtain solution E;

[0043] (5) Heat the sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com