Pump part production process

A technology of production process and parts, which is applied in the field of production process of pump parts, can solve the problems of low production efficiency and achieve the effects of convenient sand removal, shortened production cycle, and convenient positioning and pumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

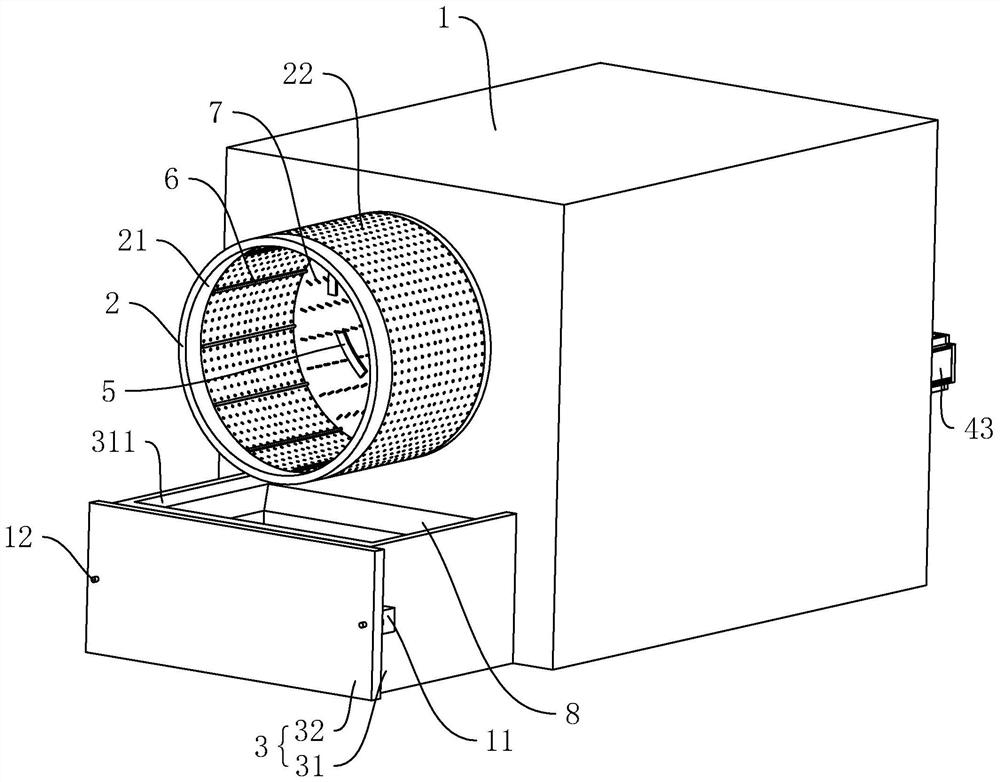

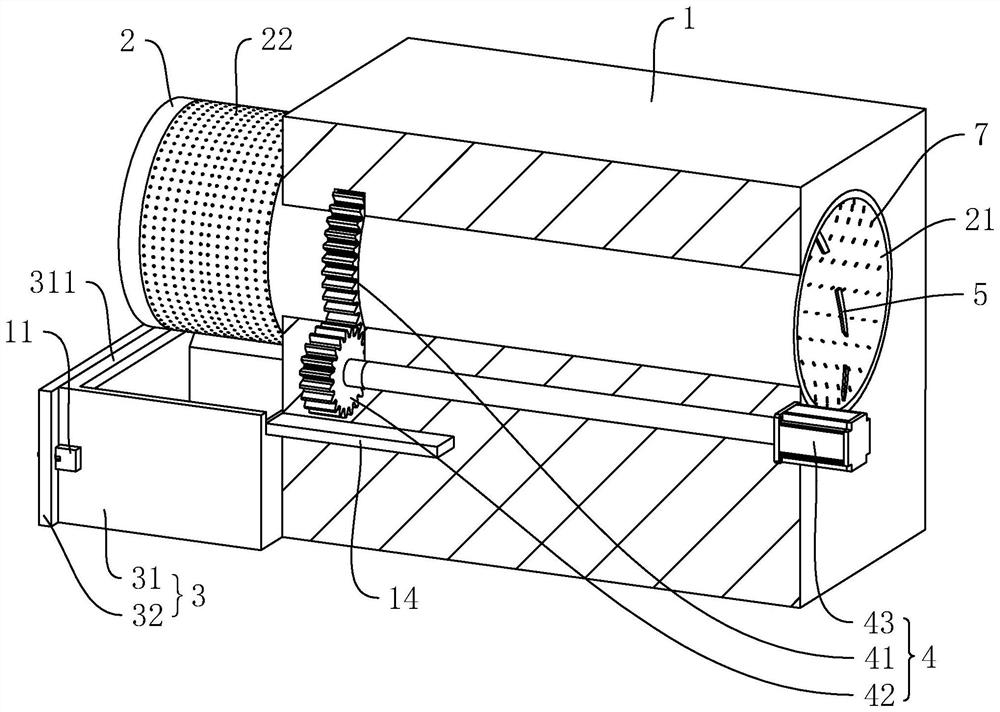

[0044] The following is attached Figure 1-7 The application is described in further detail.

[0045] The embodiment of the present application discloses a production process of pump parts, including the following steps:

[0046] a. Molding sand mold preparation: According to the size design requirements of the parts drawings, the molding sand upper mold and the molding sand lower mold are prepared, and the molding sand upper mold and the molding sand lower mold are assembled to obtain the molding sand model, and the temperature is raised to 140 ° C. After heating and curing, it is ready for use;

[0047] b. Black sand mold preparation: design and manufacture black sand upper mold and black sand lower mold according to the size requirements of the molding sand model, place the molding sand model in the black sand lower mold, and place the casting filter in the flow channel of the black sand lower mold , and then assemble the black sand upper mold and the black sand lower mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com