Rolling spraying process and system for inductor processing

An inductance and roller technology, which is applied to the surface pretreatment, spray device, and device for coating liquid on the surface, etc., can solve the problem of reducing the pass rate of inductance roller spray, difficult to ensure the surface of inductance is sprayed and painted, and easy to pile up together. and other problems to achieve the effect of improving the coating effect, facilitating disassembly and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

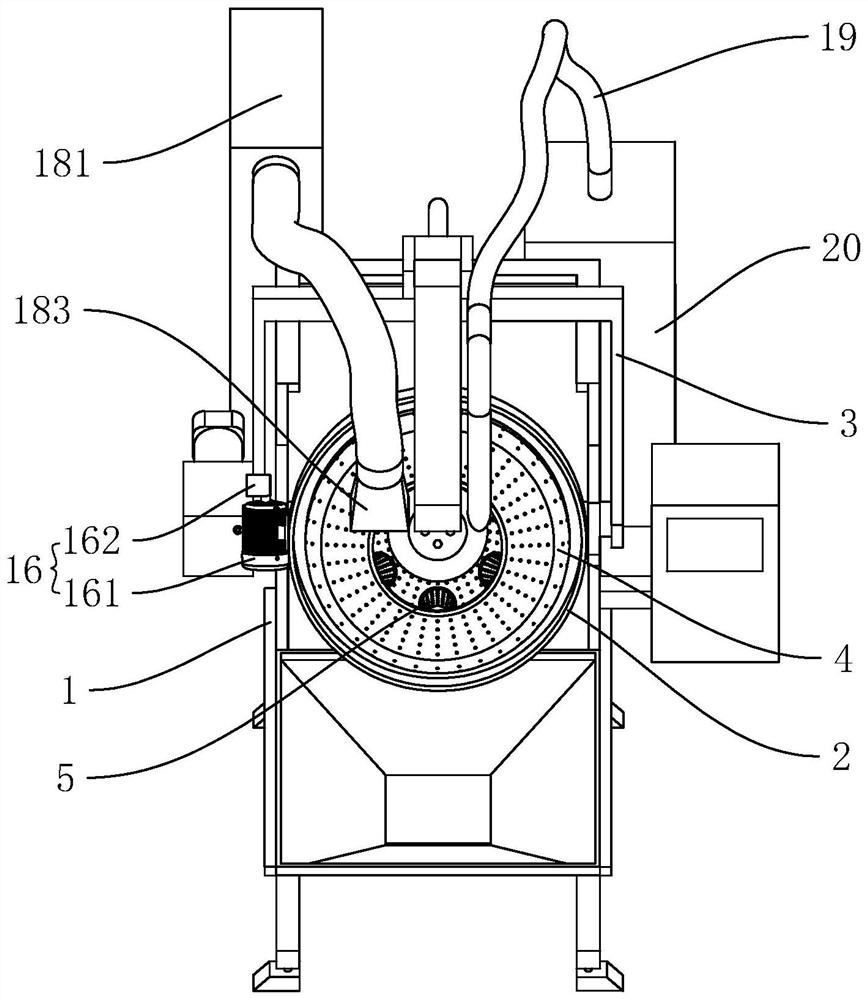

[0044] The following is attached Figure 1-4 The application is described in further detail.

[0045] In the first aspect, the embodiment of the present application discloses a rolling spray system for inductance processing. refer to figure 1 , a roll spraying system for inductance treatment includes a frame 1, a roller 2 is arranged on one side of the frame 1, and the roller 2 is installed on the side wall of the frame 1 through a bracket 3. A screen liner 4 is installed inside the drum 2, and several storage chambers 5 are arranged in the interior of the screen liner 4, and several storage rooms 5 are arranged in a circular array along the central axis of the screen liner 4. The bottom of the support 3 is equipped with a drive assembly 6 for driving the mesh inner container 4 to rotate.

[0046] Specifically, refer to figure 1 with figure 2, One end of the drum 2 is fixedly connected with the bracket 3, and the other end of the drum 2 is provided with a mouth, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com