Impurity removal process and impurity removal device for HCl for industrial production of chloromethane

A methyl chloride and process technology, which is applied in the field of HCl impurity removal process and impurity removal device for industrialized production of methyl chloride, can solve the problem of not meeting the requirement of HCl gas removal by hydrolysis of organic silicon monomers, affecting the HCl gas removal effect, The equipment cleaning operation is cumbersome and other problems, to achieve the effect of eliminating frequent blockage and parking, easy cleaning, and easy gas-solid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

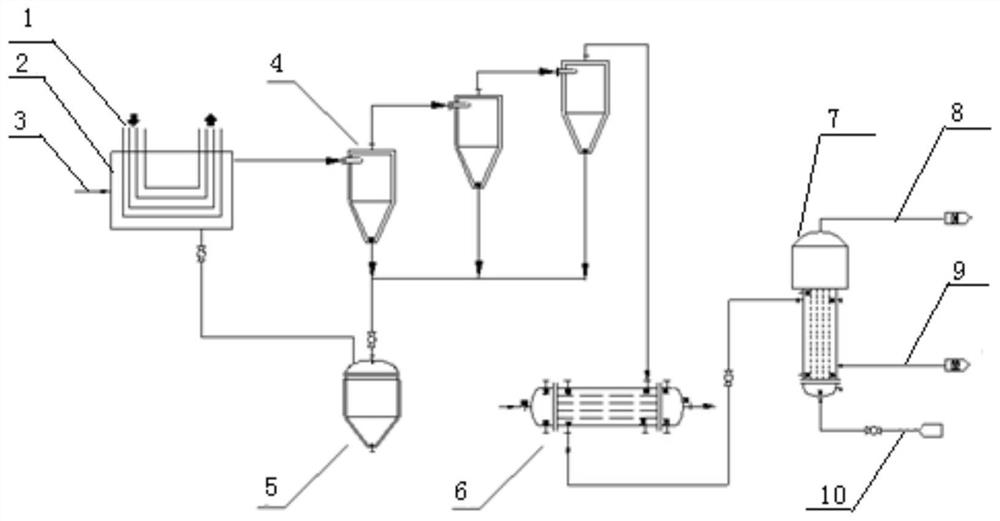

[0035] Such as figure 1 As shown, the HCl impurity removal device for the industrial production of methyl chloride includes a waste heat utilization device 2, a three-stage cyclone separator, a thermostat 6, and a methanol vaporizer 7 connected in sequence.

[0036] The heat source medium inlet of the waste heat utilization device 2 is connected to the high-temperature flue gas pipeline 1 of the organic silicon tail gas incineration boiler, the cold source medium inlet is connected to the HCl delivery pipeline 3, and the cold source medium outlet is connected to the first-stage single-cylinder cyclone of the three-stage cyclone separator 4 feeding port. The waste heat utilization device 2 uses the high-temperature flue gas of the organic silicon tail gas incineration boiler as the heat source, and the temperature is 700-1200°C. It heats the HCl gas with impurities at a high temperature. Transform into solid powdery impurities, thereby changing the difficult-to-remove oily liq...

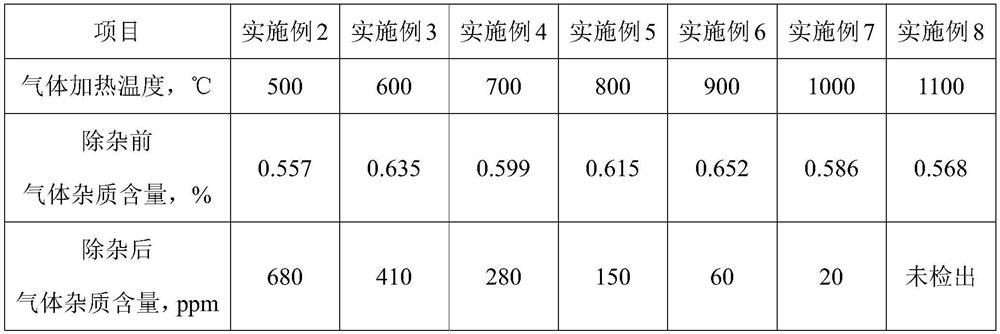

Embodiment 2-8

[0043] The impurity removal device of Example 1 is used to purify the HCl gas used in the industrial production of methyl chloride. The HCl gas comes from the hydrolysis process of the organosilicon monomer dimethyldichlorosilane. The impurities entrained in the HCl gas are a mixture of organosilicon wires and rings. Its molecular structure is a polymer containing silicon-oxygen-silicon bonds. Before entering the waste heat utilization device, the HCl gas is detected and analyzed, and the impurity content of the organic silicon wire and ring body mixture is recorded. The purification process is as follows:

[0044] Pass the impurity-containing HCl gas into the waste heat utilization device of the organosilicon tail gas incineration boiler, and at the same time detect and record the temperature of the HCl gas in the waste heat utilization device to ensure that the heating temperature of the HCl gas is above 600°C. Under high temperature conditions, the oily liquid entrained in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com