Production method of aroma-enhanced fragrant rice

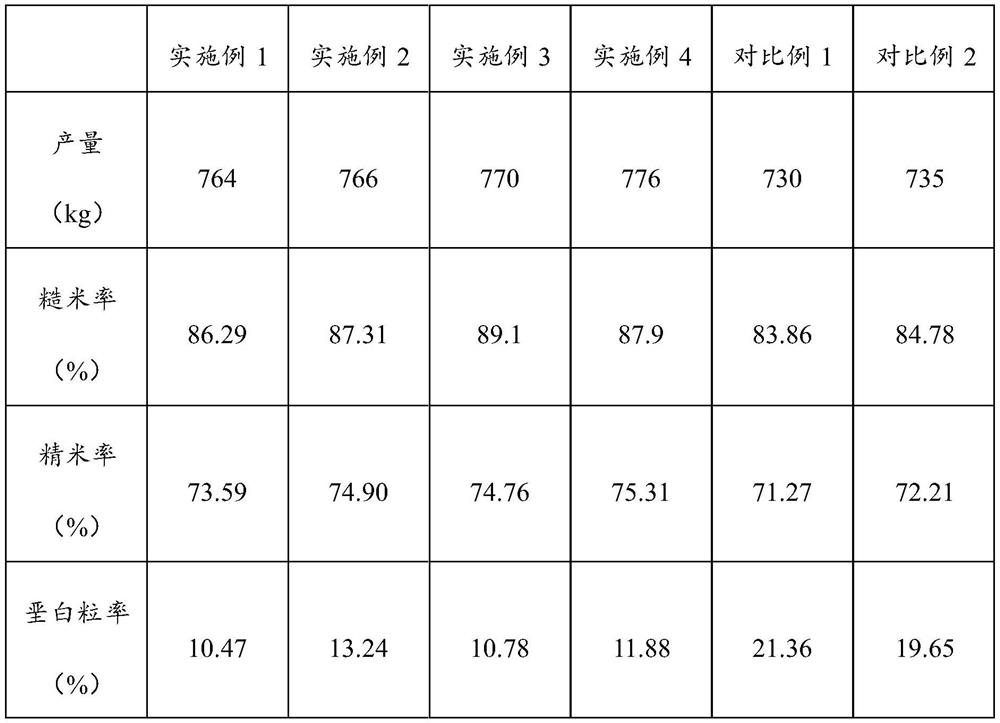

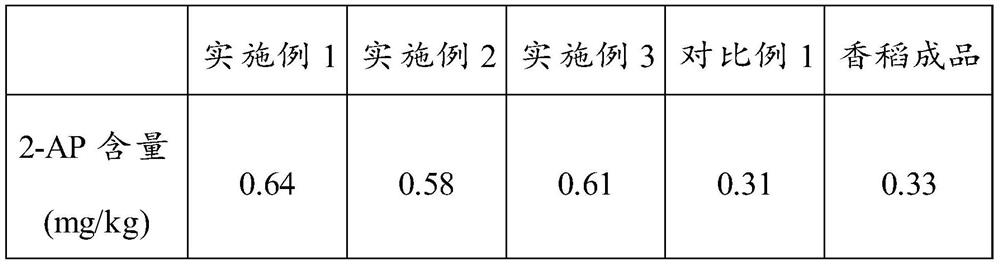

A production method and a fragrant aroma technology are applied to the production field of aroma-enhancing aroma rice, which can solve the problems of lack of aroma-rice cultivation technical standards, low natural yield, poor grain filling and the like, so as to improve the quality of aroma rice, the yield of aroma rice, and the improvement of polished rice. rate and brown rice rate, and the effect of increasing farmers' economic income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A method for producing aroma-increasing fragrant rice, the specific steps comprising:

[0058] (1) Variety selection: Guangliangxiang No. 2 was selected as the seed;

[0059] (2) Sowing and raising seedlings: the seeds are placed in a sunny and dry place to dry for 2 days, soak the sun-dried seeds for 25 minutes with 0.5% potassium permanganate solution, and after drying, process them in ultrasonic waves with a mixed frequency of 20 kHz and 40 kHz for 20 minutes. Take it out and wrap it with a wet paper towel for 1 day; put 2cm thick soil into the seedling tray, place the seedling tray on the mud surface of the seedling field to be sown and compact it, sow the above seeds in the soil and cover it with a thickness of 1cm After cultivation and germination, the seedlings to be transplanted are obtained;

[0060] (3) Soil preparation and seedling transplanting: Select second-class or above arable land close to water sources, far away from roads, fertile soil, convenient dr...

Embodiment 2

[0067] A method for producing aroma-increasing fragrant rice, the specific steps comprising:

[0068] (1) Variety selection: Guangliangxiang No. 2 was selected as the seed;

[0069] (2) Sowing and raising seedlings: the seeds are placed in a sunny and dry place to dry for 3 days, soak the sun-dried seeds for 30 minutes with 0.9% potassium permanganate solution, and after drying, process them in ultrasonic waves with a mixed frequency of 20 kHz and 40 kHz for 25 minutes. Take it out and cover it with a wet paper towel for 2 days; put 3cm thick soil into the seedling tray, place the seedling tray on the mud surface of the seedling field to be sown and compact it, sow the above seeds in the soil and cover it with a thickness of 2cm After cultivation and germination, the seedlings to be transplanted are obtained;

[0070] (3) Soil preparation and seedling transplanting: choose second-class or above arable land close to water sources, far away from roads, fertile soil, convenient ...

Embodiment 3

[0077] A method for producing aroma-increasing fragrant rice, the specific steps comprising:

[0078] (1) Variety selection: Meixiangzhan No. 2 was selected as the seed;

[0079] (2) Sowing and raising seedlings: the seeds are placed in a sunny and dry place to dry for 3 days, soak the sun-dried seeds for 30 minutes with 0.7% potassium permanganate solution, and after drying, process them in ultrasonic waves with a mixed frequency of 20 kHz and 40 kHz for 30 minutes. Take it out and cover it with a wet paper towel for 2 days; put 2cm thick soil into the seedling tray, place the seedling tray on the mud surface of the seedling field to be sown and compact it, sow the above seeds in the soil and cover it with a thickness of 2cm After cultivation and germination, the seedlings to be transplanted are obtained;

[0080] (3) Soil preparation and seedling transplanting: choose second-class or above arable land close to water sources, far away from roads, fertile soil, convenient dra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com