Commercial vehicle chassis component fatigue load spectrum extraction method

A fatigue load spectrum and extraction method technology, which is applied in the field of fatigue load spectrum extraction of commercial vehicle chassis components, can solve the problems of difficult control and determination of accuracy, divergence of model drift and non-convergence, and inaccuracy of excitation response accuracy of vehicle multi-body dynamics models. Get verification and other issues to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

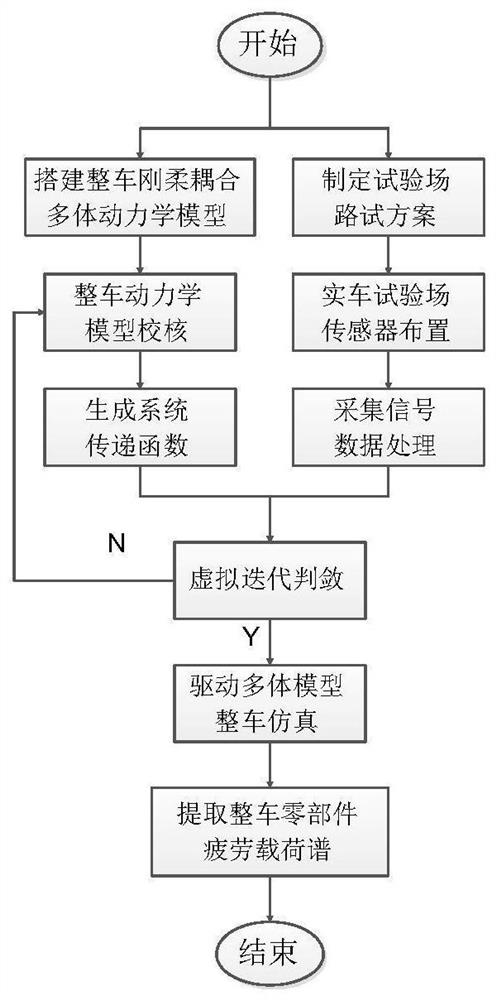

[0040] refer to Figure 1-9 , as an embodiment of the present invention, provides a method for extracting fatigue load spectrum of chassis components of a commercial vehicle, including:

[0041] S1: Develop a road test plan for the proving ground and collect durable road surface signals of the actual vehicle proving ground;

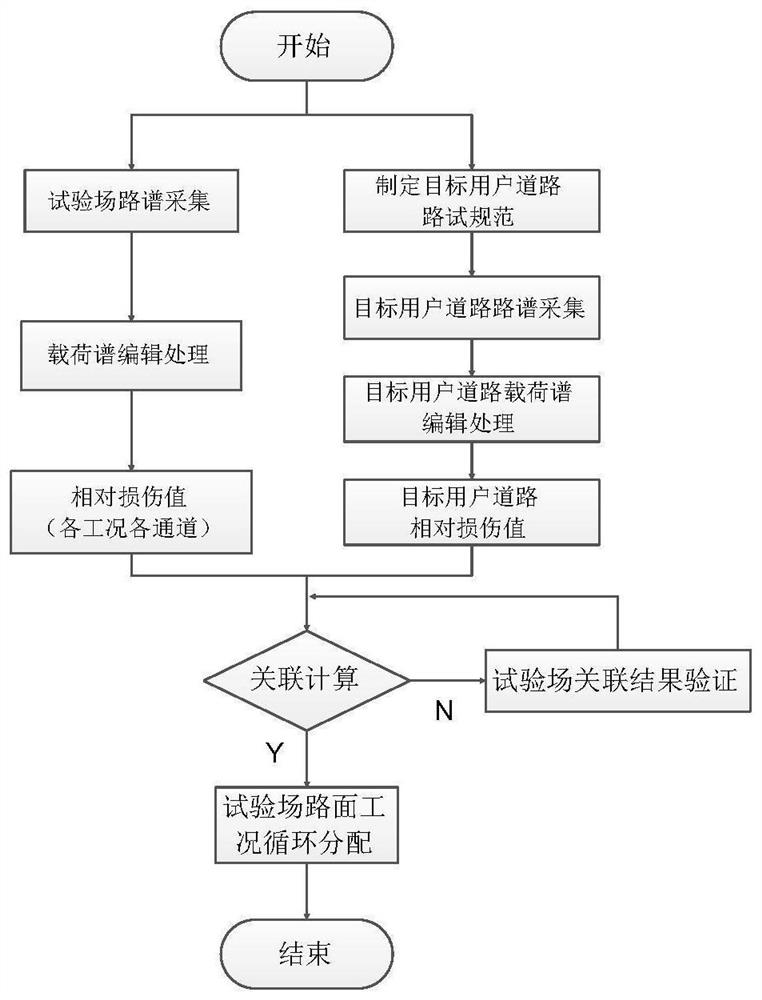

[0042] Specifically, such as Figure 2~3 Shown:

[0043] (1) Based on the principle of damage equivalence, correlate the mileage of the target user with the mileage of the strengthened road surface of the proving ground, that is, optimize the pavement combination of the proving ground, so that the pseudo damage value caused by the proving ground combined road and the actual user road is consistent. The number of cycles of the road surface, so that the pseudo-damage value of each load channel is consistent with the pseudo-damage value of the user's actual driving road;

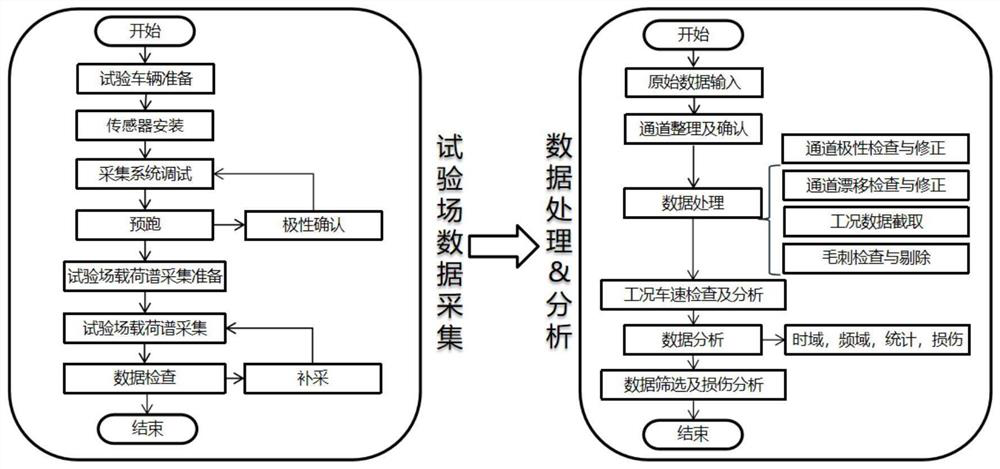

[0044] (2) Acquisition of durable road surface signals in the real vehicle test sit...

Embodiment 2

[0065] refer to Figure 10 It is another embodiment of the present invention, which is different from the first embodiment in that it provides a verification test of a method for extracting the fatigue load spectrum of a commercial vehicle chassis component, in order to verify the technical effect adopted in this method To illustrate, this embodiment conducts a verification test on the method of the present invention based on an actual application scenario, and verifies the real effect of the method by means of scientific demonstration.

[0066] Aiming at the problem that the fatigue load spectrum of commercial vehicle chassis components is difficult to obtain, the six-component force data of the wheel center is collected by arranging a sextant force meter, and the fatigue load spectrum of the chassis components of the vehicle is extracted by combining multi-body dynamics with the principle of cycle iteration; in Adams / A rigid-flexible coupling multi-body dynamics model of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com