Liquid ammonia sampling device

A sampling device and liquid ammonia technology, applied in the field of liquid ammonia, can solve the problems of cumbersome process, human error, danger, etc., and achieve the effect of simple sampling process and changing contact distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] The embodiment of the present invention discloses a liquid ammonia sampling device, comprising:

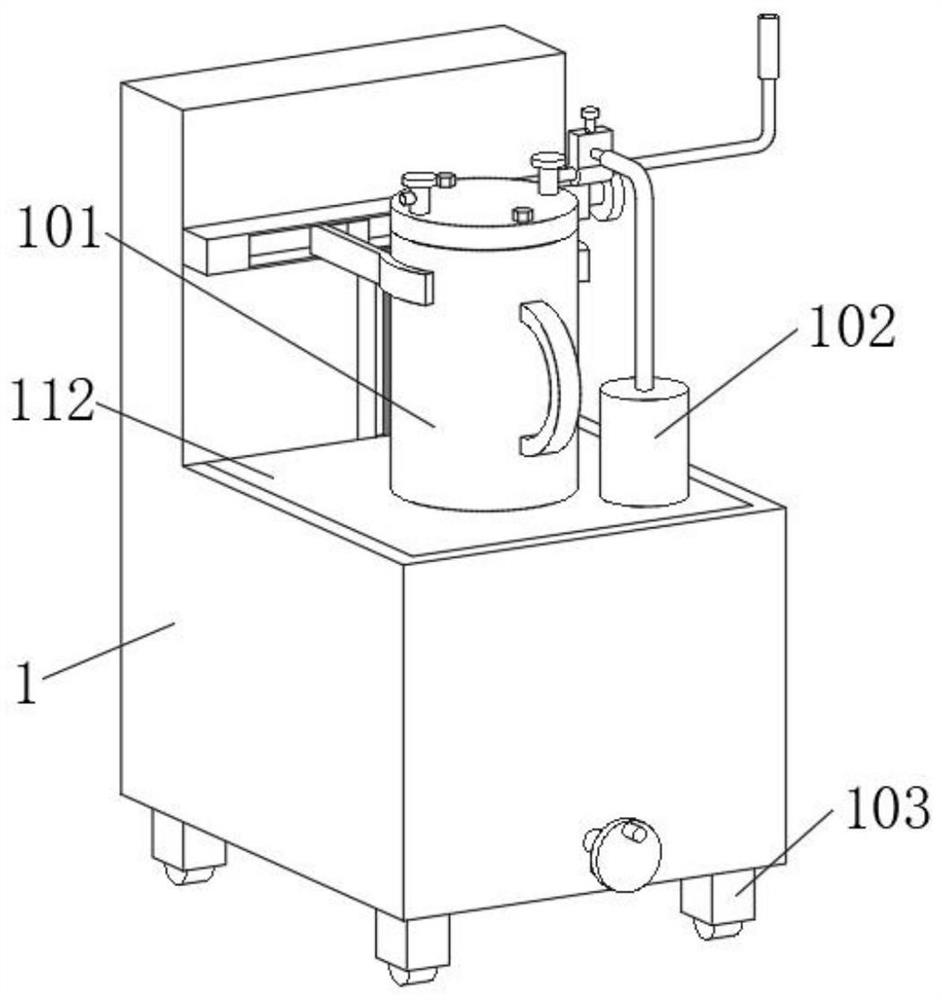

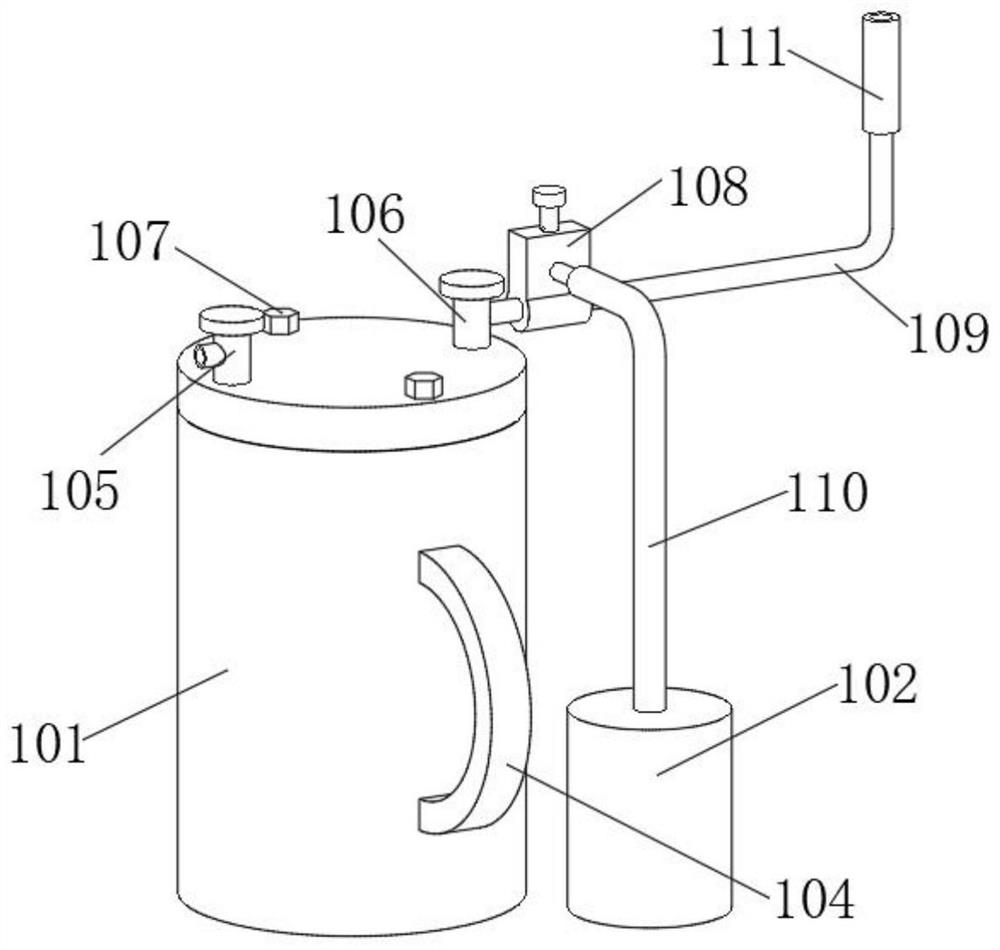

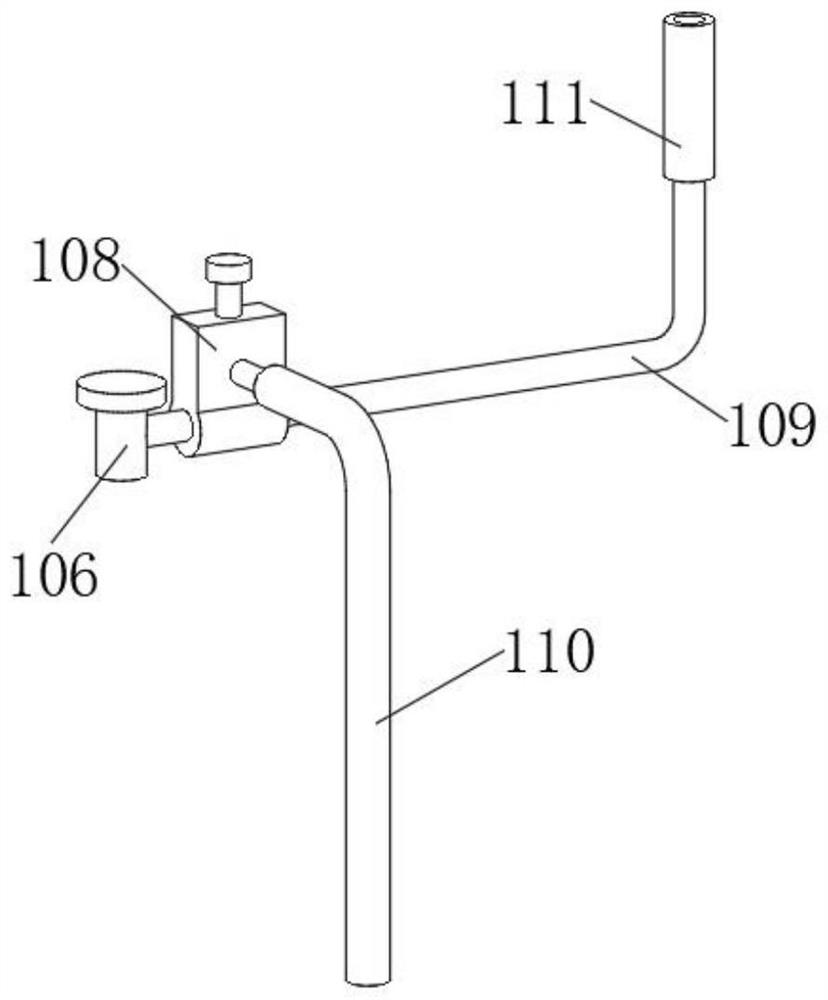

[0079] Base 1, a steel cylinder sampling tank 101 and a liquid ammonia temporary storage tank 102 are arranged above the connecting plate 112 of the base 1, four pulleys 103 are fixedly connected to the lower surface of the base 1, and a sealing cover is arranged above the steel cylinder sampling tank 101. The upper surface is provided with a liquid outlet valve 105 and a liquid inlet valve 106, and one end of the liquid inlet valve 106 is connected with a liquid nitrogen transfer seat 108;

[0080] The connecting plate 112 is slidably connected to the inner wall of the base 1, the lower surface of the connecting plate 112 is fixedly connected with the extrusion spring 301, and an inductor 506 is arranged below the connecting plate 112;

[0081] Blocking the liquid limiting assembly 2, the blocking liquid limiting assembly 2 includes a blocking block 201 and a cylinder 203,...

Embodiment 2

[0093] The embodiment of the present invention discloses a liquid ammonia sampling device, comprising:

[0094] Base 1, a steel cylinder sampling tank 101 and a liquid ammonia temporary storage tank 102 are arranged above the connecting plate 112 of the base 1, four pulleys 103 are fixedly connected to the lower surface of the base 1, and a sealing cover is arranged above the steel cylinder sampling tank 101. The upper surface is provided with a liquid outlet valve 105 and a liquid inlet valve 106, and one end of the liquid inlet valve 106 is connected with a liquid nitrogen transfer seat 108;

[0095] The connection plate 112 is slidably connected to the inner wall of the base 1, the lower surface of the connection plate 112 is fixedly connected with the extrusion spring 301, and the sensor 506 is arranged under the connection plate 112; Block 201 and cylinder 203, block block 201 is slidably connected on the inner wall of liquid nitrogen transfer seat 108;

[0096] The slid...

Embodiment 3

[0106] The embodiment of the present invention discloses a liquid ammonia sampling device, comprising:

[0107]Base 1, a steel cylinder sampling tank 101 and a liquid ammonia temporary storage tank 102 are arranged above the connecting plate 112 of the base 1, four pulleys 103 are fixedly connected to the lower surface of the base 1, and a sealing cover is arranged above the steel cylinder sampling tank 101. The upper surface is provided with a liquid outlet valve 105 and a liquid inlet valve 106, and one end of the liquid inlet valve 106 is connected with a liquid nitrogen transfer seat 108;

[0108] The connection plate 112 is slidably connected to the inner wall of the base 1, the lower surface of the connection plate 112 is fixedly connected with the extrusion spring 301, and the sensor 506 is arranged under the connection plate 112; Block 201 and cylinder 203, block block 201 is slidably connected on the inner wall of liquid nitrogen transfer seat 108;

[0109] The slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com