Automatic monitoring and early warning system and monitoring method for sealing performance of power battery pack

A power battery pack, automatic monitoring technology, applied in liquid tightness measurement using liquid/vacuum degree, by measuring the increase and deceleration rate of the fluid, and by detecting the appearance of the fluid at the leakage point, etc., it can solve the problems of water ingress in the power battery, Power battery airtight failure, complex working links and other issues, to achieve high reliability, shorten the monitoring cycle and monitoring costs, simple and convenient working process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0040] Example 1

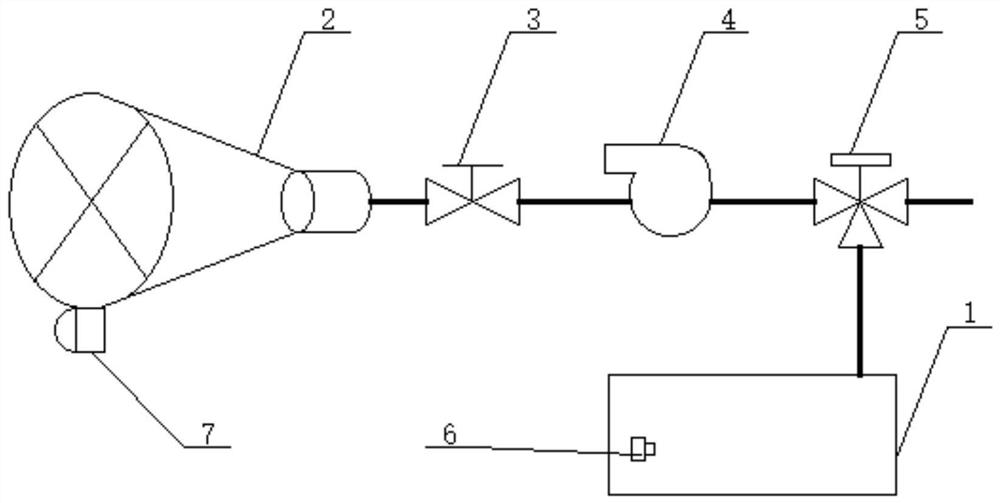

[0041] Join figure 1 with 2 The technical solution of the present invention is a power battery pack sealing automatic monitoring early warning system, including power battery pack 1, purifying device 2, a first solenoid valve 3, an air pump 4, a second solenoid valve 5, a control unit 8, a pressure sensor 6, water-related sensor 7, automotive electrical control system 9 and air pump current detecting unit 10, the purification device 2, the first solenoid valve 3, the air pump 4 and the second solenoid valve 5 are sequentially connected to the intake air path channel, The first solenoid valve 3 is a two-way solenoid valve, the second solenoid valve 5 being a three-way solenoid valve, the input port of the first solenoid valve 3 connects the output port of the purge apparatus 2, the first solenoid valve 3 The output of the air pump 4 is connected to the input port of the air pump 4, and the input port of the second solenoid valve 5 connects the output of the air p...

Example Embodiment

[0043] Example 2

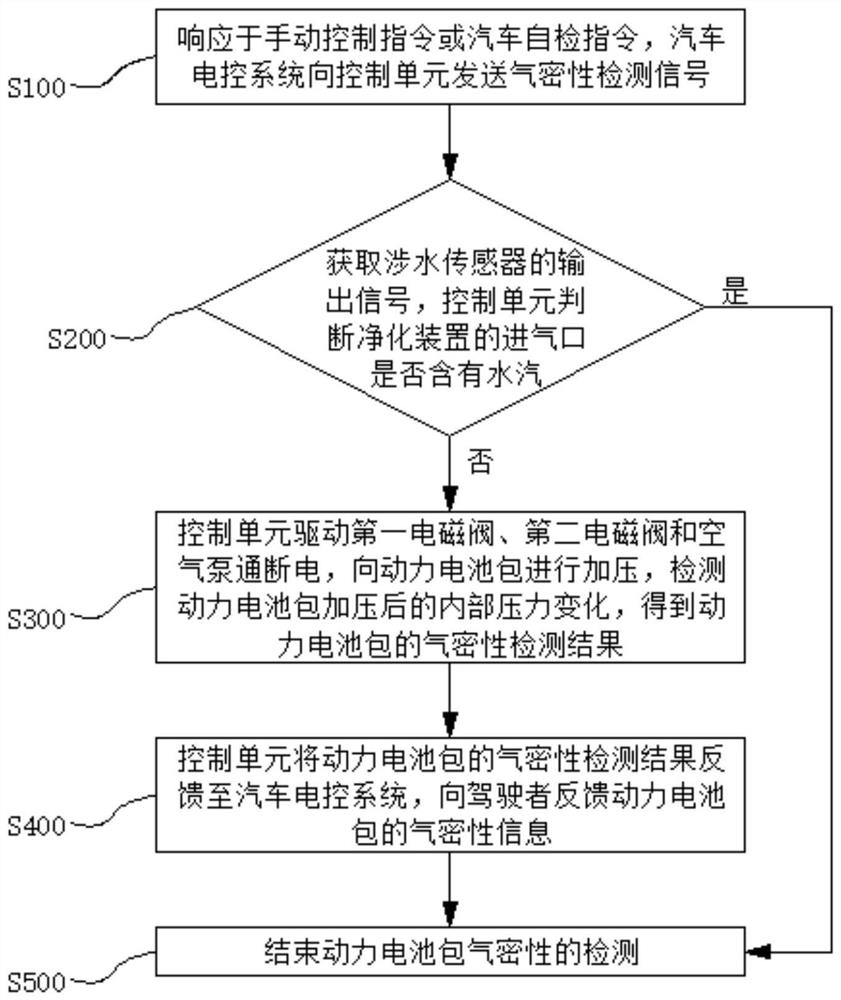

[0044] Join image 3 with 4 The technical solution of the present invention is an automatic warning monitoring method according to the power battery pack, which includes the following steps:

[0045] S100, in response to manual control instruction or car self-test instruction, the automotive electrical control system transmits a hermetic detection signal to the control unit;

[0046] S200, acquire the output signal of the water-related sensor, the control unit determines the environment in which the air intake port of the purge apparatus is obtained; if the control unit determines that the venting port of the purge apparatus contains water vapor, the airtight detection operation of the power battery pack is ended; if control The unit judges that the intake port of the purification device does not contain water vapor, and the airtight detection operation of the power battery pack is continued;

[0047] S300, the control unit drives the first solenoid valve, the se...

Example Embodiment

[0055] Example 3

[0056] Join Figure 5 with 6 A automatic warning monitoring method of a power battery pack, which uses the above-described automatic monitoring warning system, including the following steps:

[0057] S100, in response to manual control instruction or car self-test instruction, the automotive electrical control system transmits a hermetic detection signal to the control unit;

[0058] S200, acquire the output signal of the water-related sensor, the control unit determines the environment in which the air intake port of the purge apparatus is obtained; if the control unit determines that the venting port of the purge apparatus contains water vapor, the airtight detection operation of the power battery pack is ended; if control The unit judges that the intake port of the purification device does not contain water vapor, and the airtight detection operation of the power battery pack is continued;

[0059] S300, the control unit drives the first solenoid valve, the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com