Automatic discharging device for cold stamping composite die

A technology of automatic discharge device and composite mold, applied in the field of stamping processing equipment, can solve the problems of difficult to take out stamping parts, unable to meet mass production, low efficiency, etc., to achieve simple working process, improve production efficiency and production safety. , safe to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with specific drawings and embodiments.

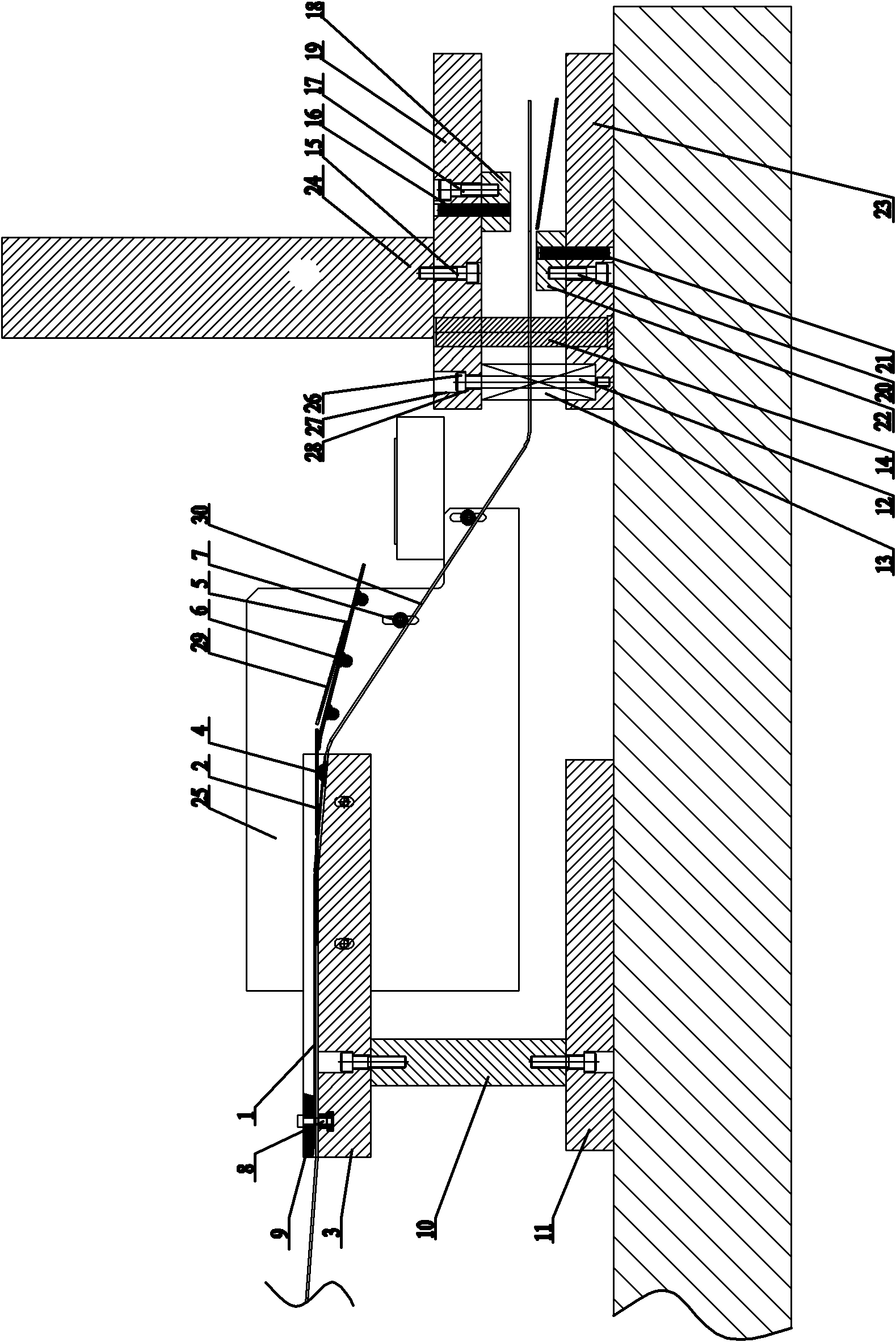

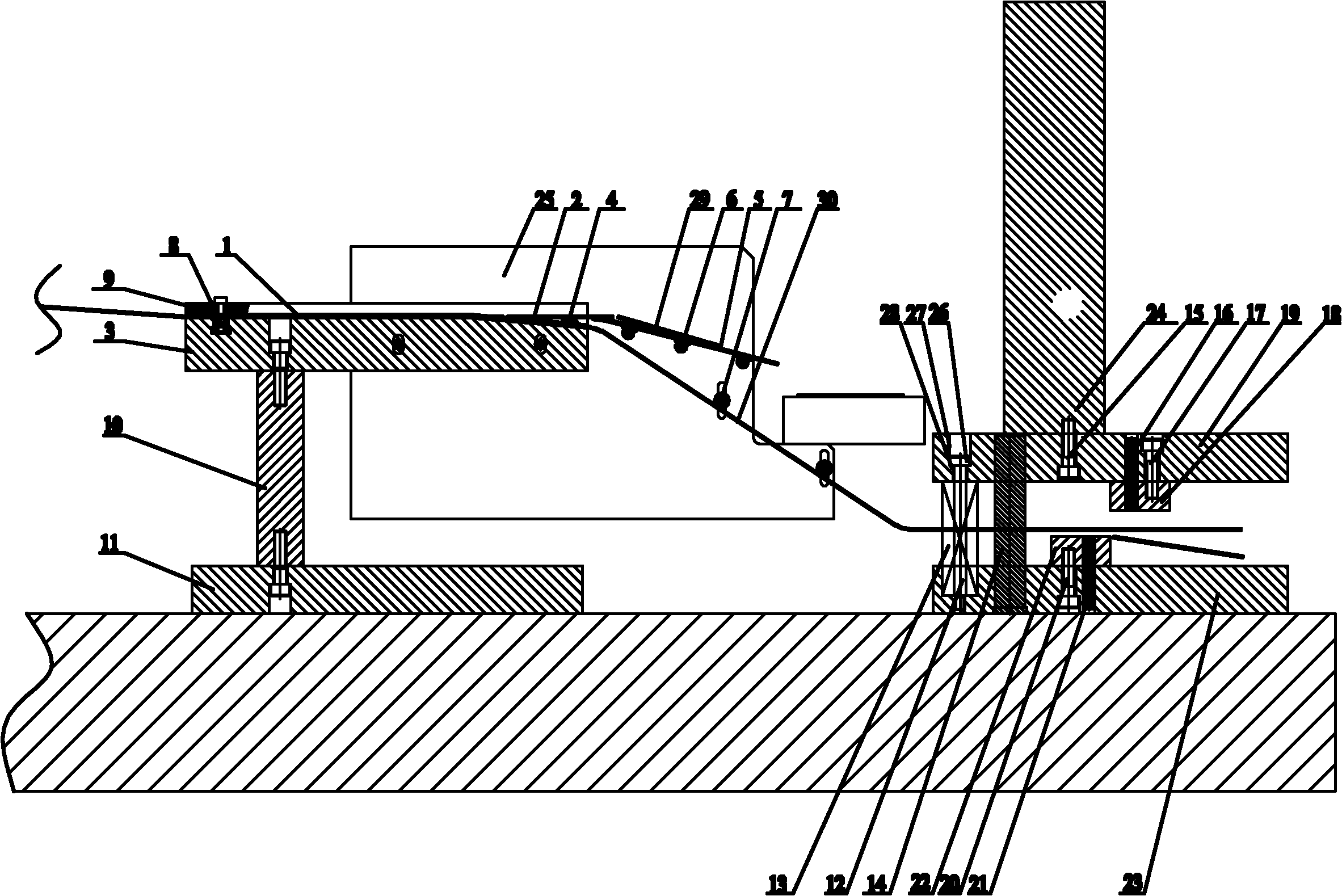

[0010] As shown in the figure: the present invention mainly consists of a guide groove horizontal section 1, a guide groove downhill section 2, a base plate 3, a top block 4, a slide plate 5, a pressing rod 7, a pressing block 8, a guide plate 9, a mold foot 10, and a supporting plate 11. Unloading screw 12, spring 13, guide post 14, screw 15, positioning pin 16, screw 17, punch 18, upper die base 19, screw 20, positioning pin 21, die insert 22, lower die base 23 , lifting column 24, back plate 25, limit nut 26, slide hole 27 and devices such as steps 28 in the slide hole are formed.

[0011] The cold stamping composite mold automatic discharge device includes a mold foot 10 fixedly installed on the supporting plate 11, a base plate 3 is fixedly installed on the mold foot 10, a guide plate 9 is fixedly installed on the base plate 3 through a pressing block 8, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com