Frock clamp for removal of waste of doll toy injection molding parts and use method

A tooling fixture and injection molded parts technology, which is applied in the field of waste removal tooling fixtures for injection molded parts, can solve problems such as low work efficiency, lack of pick-and-place devices, and difficult work completion, and achieve the effects of easy handling, good positioning effect, and simple working process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

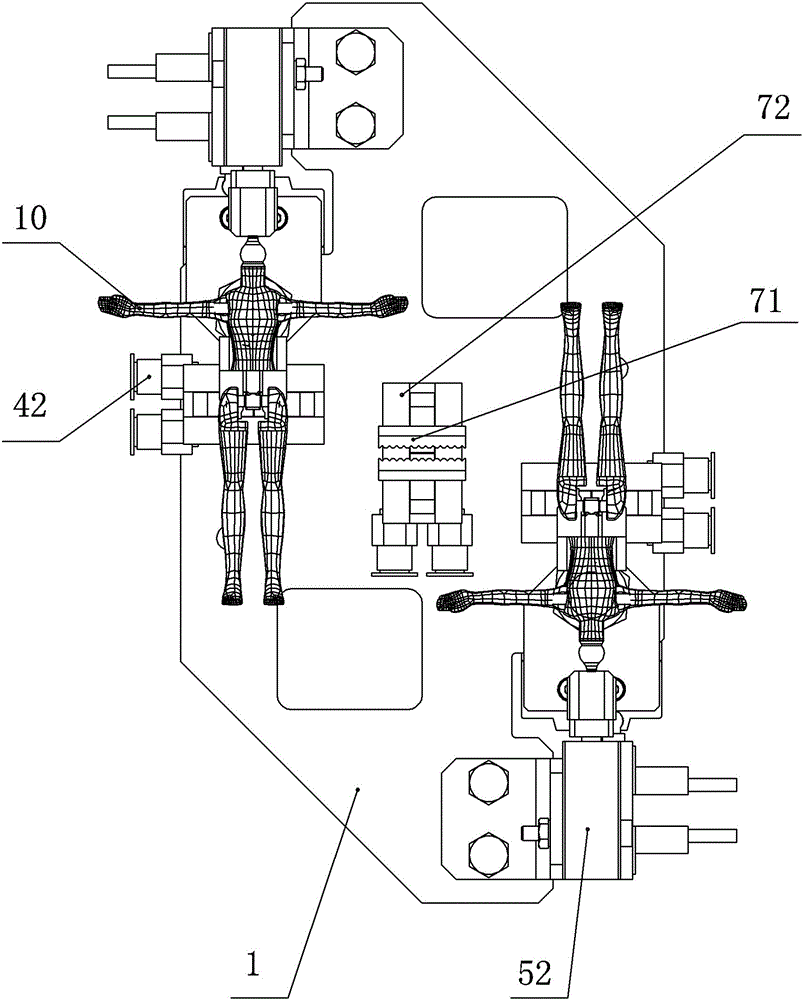

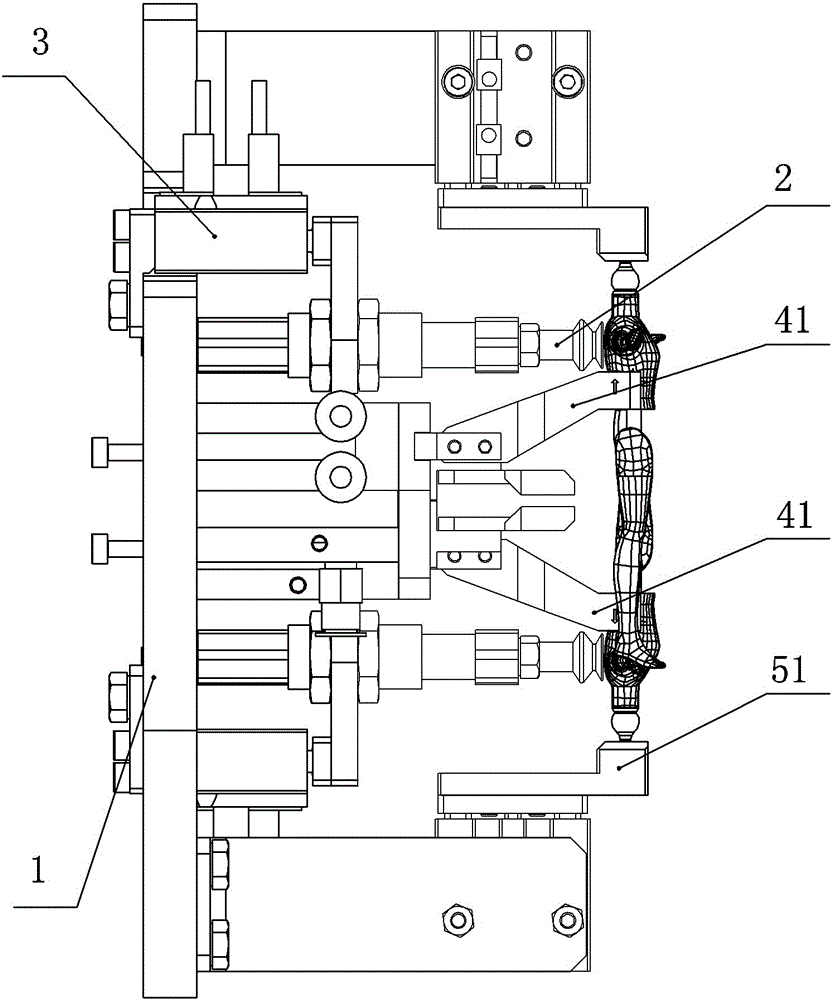

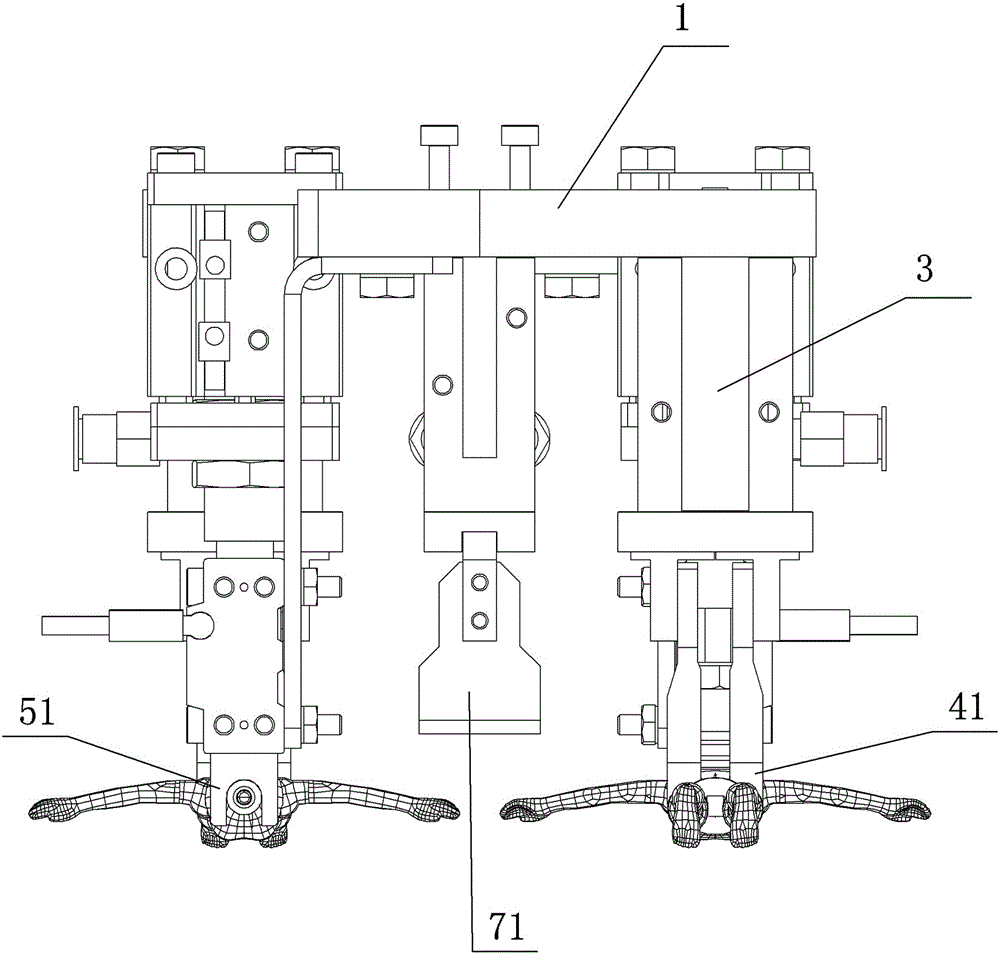

[0018] A tooling fixture for waste removal of doll toy injection molded parts, comprising a mounting plate 1 mounted on a robot manipulator and moving with the manipulator, a suction cup 2 for absorbing the back of a doll toy injection molded part 10, and a cylinder 3 for driving the suction cup to move on the mounting plate, There is also a gripper that can be opened and closed to grab and place the injection molded parts of the doll toy; the neck of the injection molded part of the doll toy is provided with a drainage port 11 for discharging waste, and a material removal device for opening the drainage port and allowing the waste to discharge is installed on the mounting plate. For the device, a waterway for discharging waste is also arranged on the mounting plate, the waterway is connected to the drain of the doll toy injection molded part, and the water outlet of the waterway is provided with a waste clip for clamping the waste of the waterway.

[0019] The gripper includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com