Double-cylinder type steam drying system

A drying system, double-cylinder technology, applied in the field of dryers, can solve the problems of increasing the difficulty of processing and assembly, increasing production costs, and large energy consumption, so as to increase the effect of water sealing, reduce maintenance costs, and reduce construction costs. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

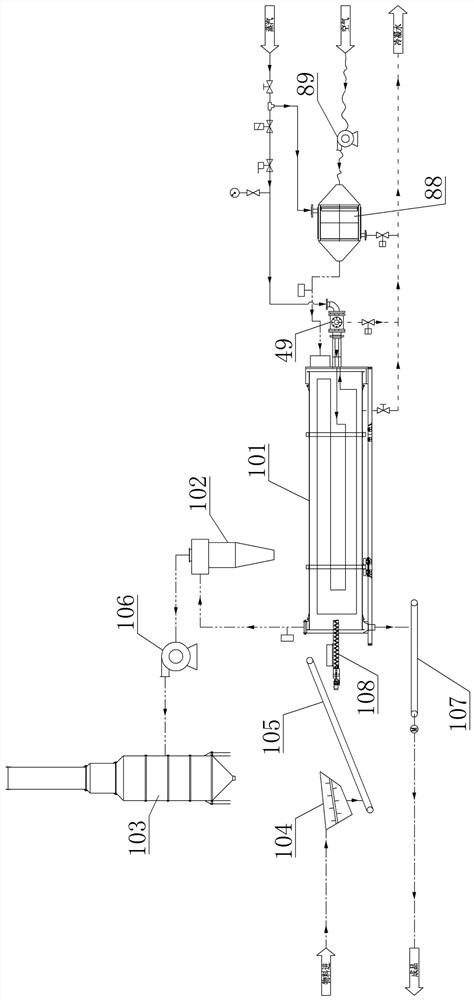

[0049] Embodiment one, see Figure 1-24 , double-cylinder steam drying system, the system includes a double-cylinder steam dryer, a steam heat exchange and air distribution device that provides hot air to the inside of the double-cylinder steam dryer;

[0050] The double-cylinder steam dryer includes a frame and a multi-stage cylinder group rollingly mounted on the frame; the multi-stage cylinder group includes an inner cylinder and an outer cylinder coaxially set outside the inner cylinder body, the inner cylinder body and the outer cylinder body are both cylindrical and fixed coaxially; the inner wall of the inner cylinder body is fixed with a number of first-level heat dissipation pipes uniformly distributed along its inner circumference , and each first-level heat dissipation pipe A is arranged along the direction of the busbar of the inner cylinder body, and the two ends of each first-level heat dissipation pipe A are sealed and connected with the first-level summary pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com