Hammering device for pavement marking and use method

A technology of road marking and hammering device, which is applied in the direction of roads, roads, road repairs, etc., can solve the problems of easily damaged road markings, and achieve the effects of saving costs, reducing the probability of damage, and reducing manpower and material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

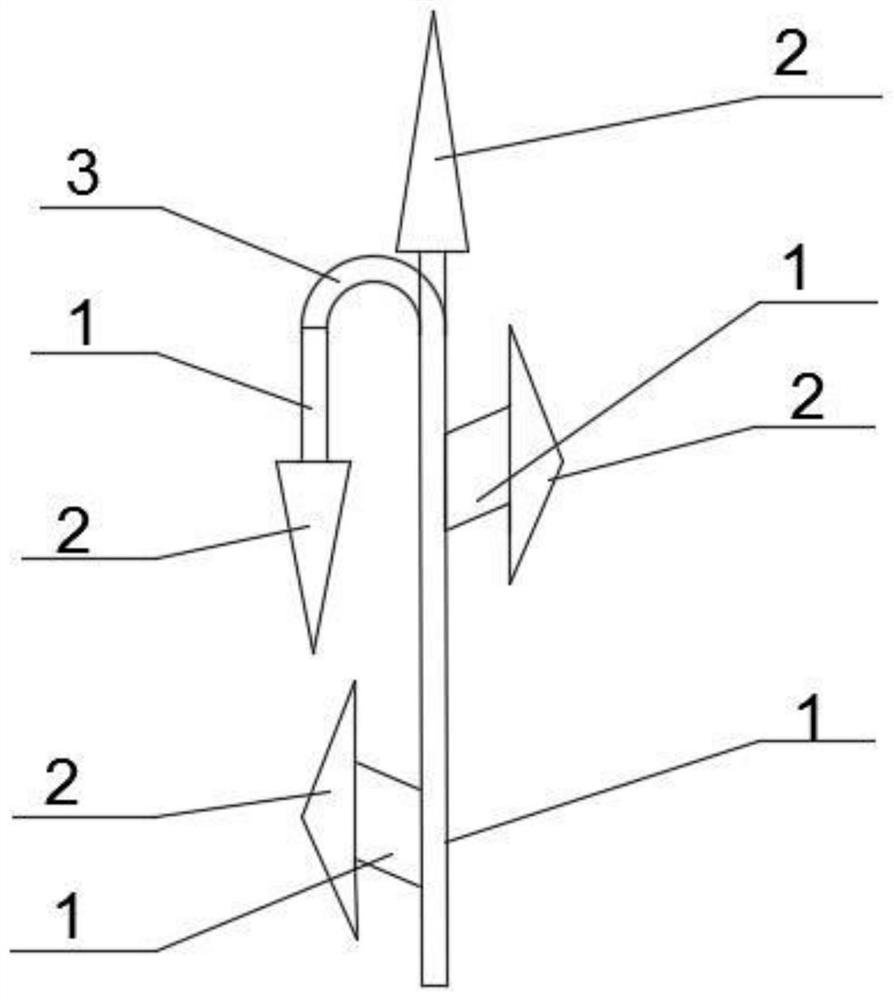

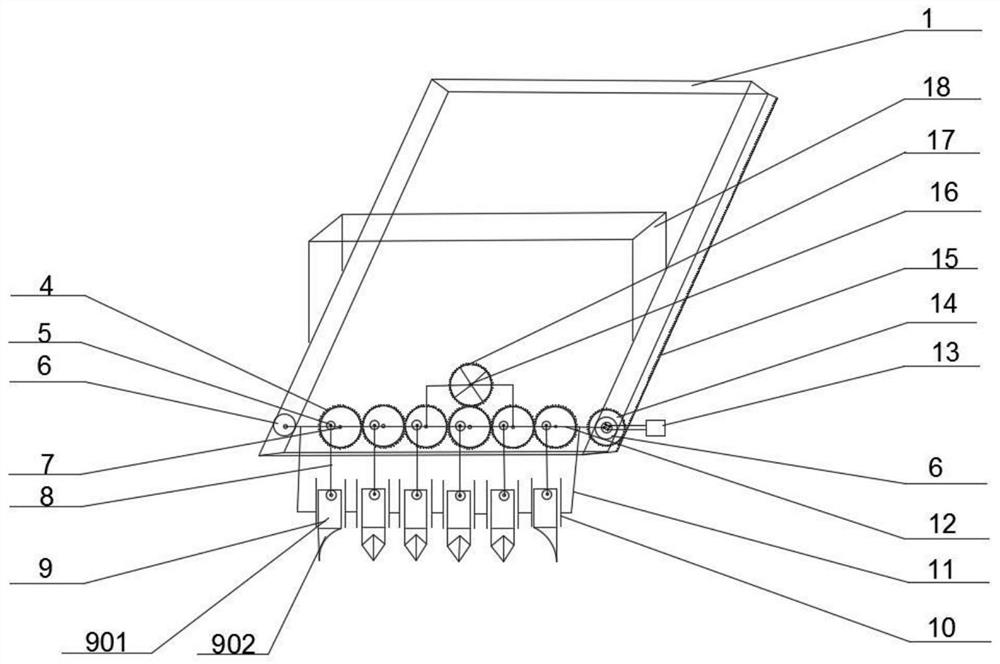

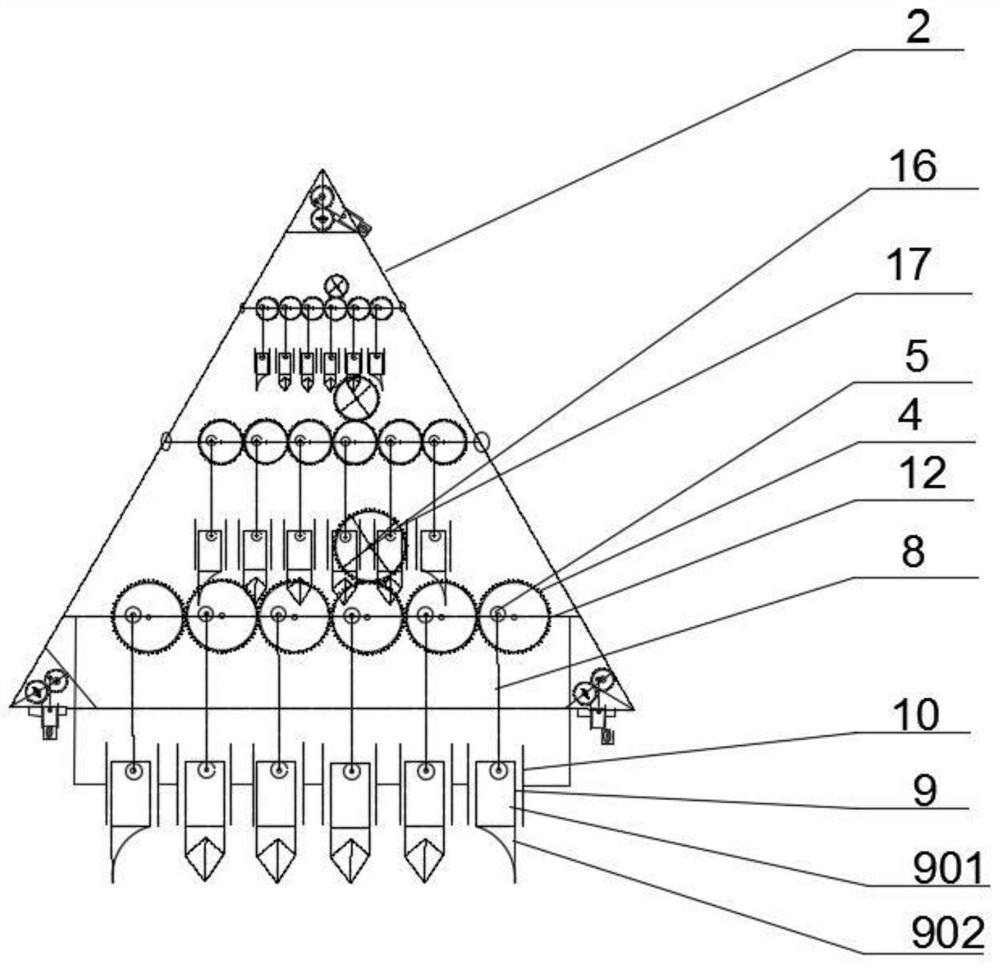

[0042] Such as figure 2 , image 3 As shown, this embodiment is a hammering device for road markings, including a hammering module. The hammering module includes a reciprocating linear motion mechanism and a plurality of hammer heads 9 connected with the reciprocating linear motion mechanism. The reciprocating linear motion mechanism is used for The vertical reciprocating movement of the hammer head 9 is controlled to repeatedly hammer the road marking pattern. The hammering module is installed in a frame consistent with the road marking pattern, and the movement direction of the hammering module is perpendicular to the frame plane. The frame is provided with frame connectors 18, and the frame connectors 18 are used to install the frame on the mobile vehicle.

[0043] The reciprocating linear motion mechanism comprises a driven gear 4, a driving gear 17 and a first drive motor 16 for driving the driving gear 17. The number of the driven gears 4 is multiple and is respectivel...

Embodiment 2

[0063] The main structure of the second embodiment is the same as that of the first embodiment, the difference is that the second embodiment also includes an identification module and a controller, and the identification module is an image acquisition device (the accompanying drawing is a display) for marking road marking patterns (such as Figure 17 shown) to collect and transmit the collected image signal to the controller, the controller recognizes the corresponding marking line according to the image, and controls the hammering module to hammer the pavement marking pattern according to the recognition result to form the recognized marking line Groove with consistent line pattern.

[0064] Embodiment 2 is suitable for redrawing marking lines on road surfaces on which marking lines have already been drawn.

[0065] A method for using a hammering device for pavement markings, the specific method includes the following steps:

[0066] First, the assembled hammering device is ...

Embodiment 3

[0073] Such as Figure 5 As shown, the main structure of the third embodiment is the same as that of the first embodiment or the second embodiment, and the difference is that edge gears 26 are respectively arranged on both sides of the driven gear 4 of the reciprocating linear motion mechanism of the third embodiment, and the eccentricity of the edge gear 26 The shaft is connected with edge hammer 27 for hammering the curb, the connection mode between edge gear 26 and edge hammer 27 is consistent with the connection mode between driven gear 4 and its corresponding hammer 9, each edge gear 26 is equipped with respectively An edge driving gear 19 and an edge driving motor 20 for driving the edge driving gear 19, the edge driving gear 19 meshes with the edge gear 26, the edge driving motor 20 drives the edge driving gear 19 to rotate so as to drive the edge gear 26 to rotate, and finally controls the edge The hammer head 27 hammers the ground repeatedly, the shape of the working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com