Four-side centering clamp and batch clamping system

A technology of dividing the fixture and dividing the slot, applied in the direction of clamping, positioning device, manufacturing tool, etc., can solve the time of clamping and calibration and the time of external clamping, the requirement of high technical level of workers, and the processing of machine tools. Problems such as low part efficiency, to reduce the clamping time, improve the processing efficiency, and shorten the time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

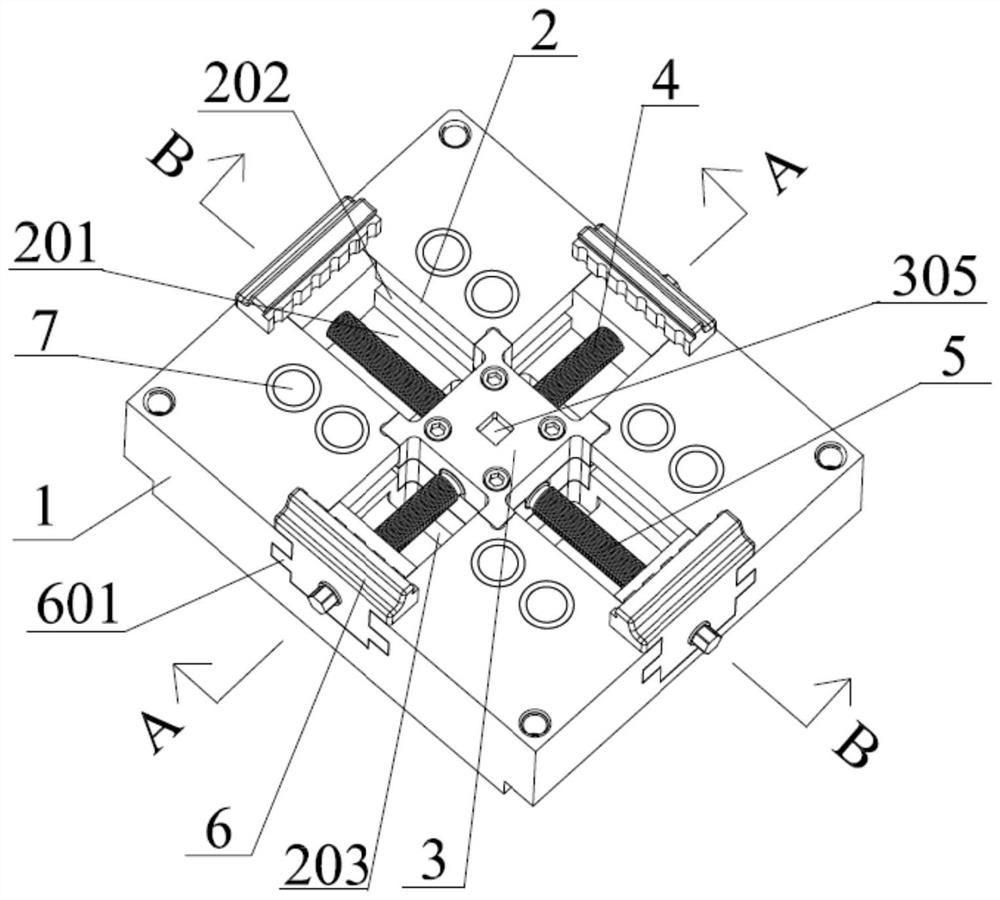

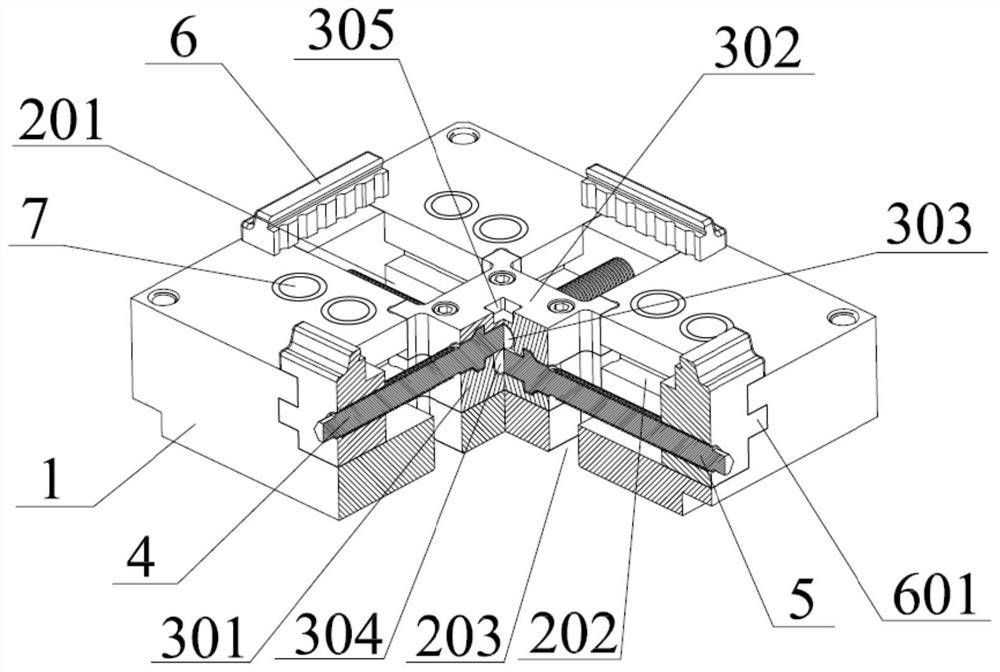

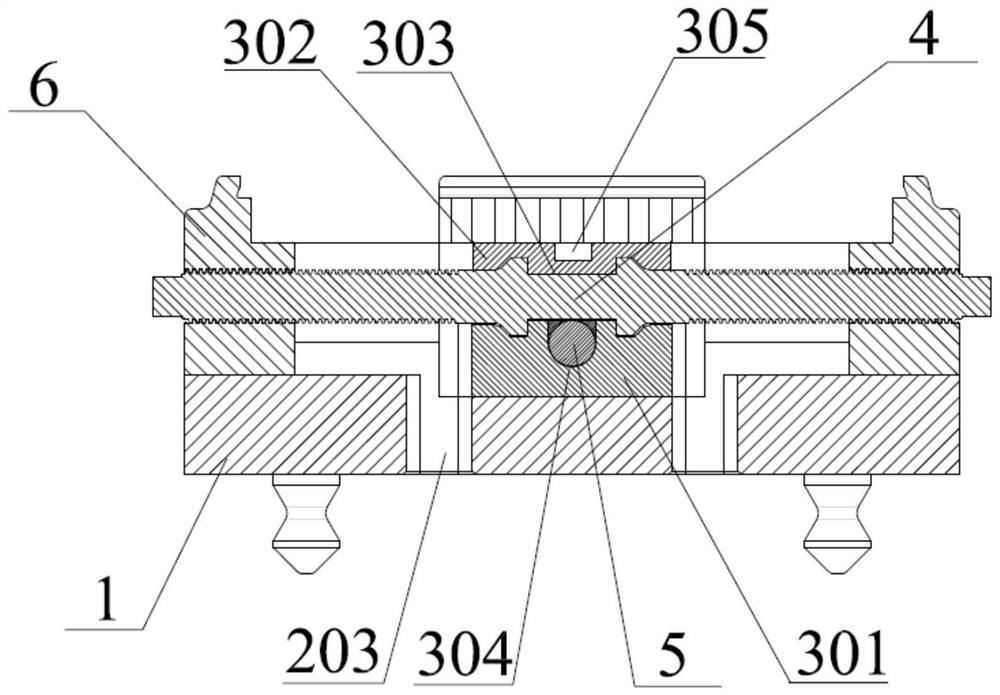

[0034] Such as Figure 1-Figure 4 As shown, a four-sided centering fixture includes a base 1, a cross groove 2 is provided on the base 1, a screw positioning block 3 is provided at the center of the cross groove 2, and the screw positioning block 3 is threaded with a first screw rod 4 and The second screw mandrel 5, the first screw mandrel 4 and the second screw mandrel 5 are arranged in a dislocation up and down, in the present embodiment the first screw mandrel 4 is placed above the second screw mandrel 5, certainly the first screw mandrel 4 Placed below the second screw mandrel 5, and the first screw mandrel 4 and the second screw mandrel 5 are placed in the cross groove 2 in a cross shape, and both ends of the first screw mandrel 4 and the second screw mandrel 5 are threadedly connected with Locking block 6, locking block 6 is slidingly connected with cross groove 2, the thread directions of both ends of the first screw rod 4 and the second screw rod 5 are opposite, one en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com