Aluminum plate paint spraying assembly line

An assembly line, aluminum plate technology, applied in the direction of spraying device, can solve the problem of heavy labor of the staff, achieve the effect of improving spraying efficiency, reducing the process of turning over the aluminum plate, and reducing the blank space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

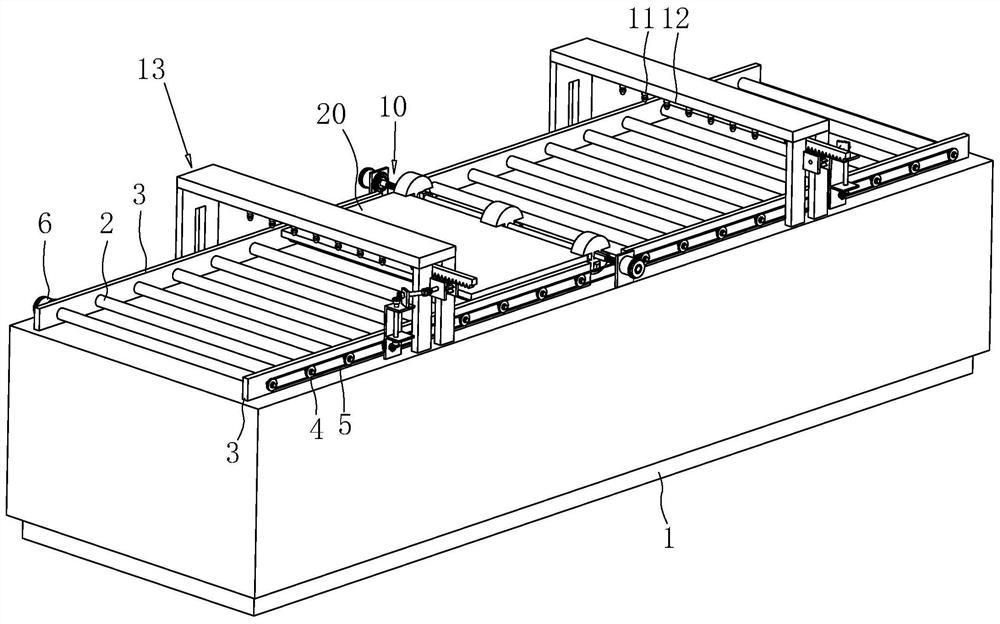

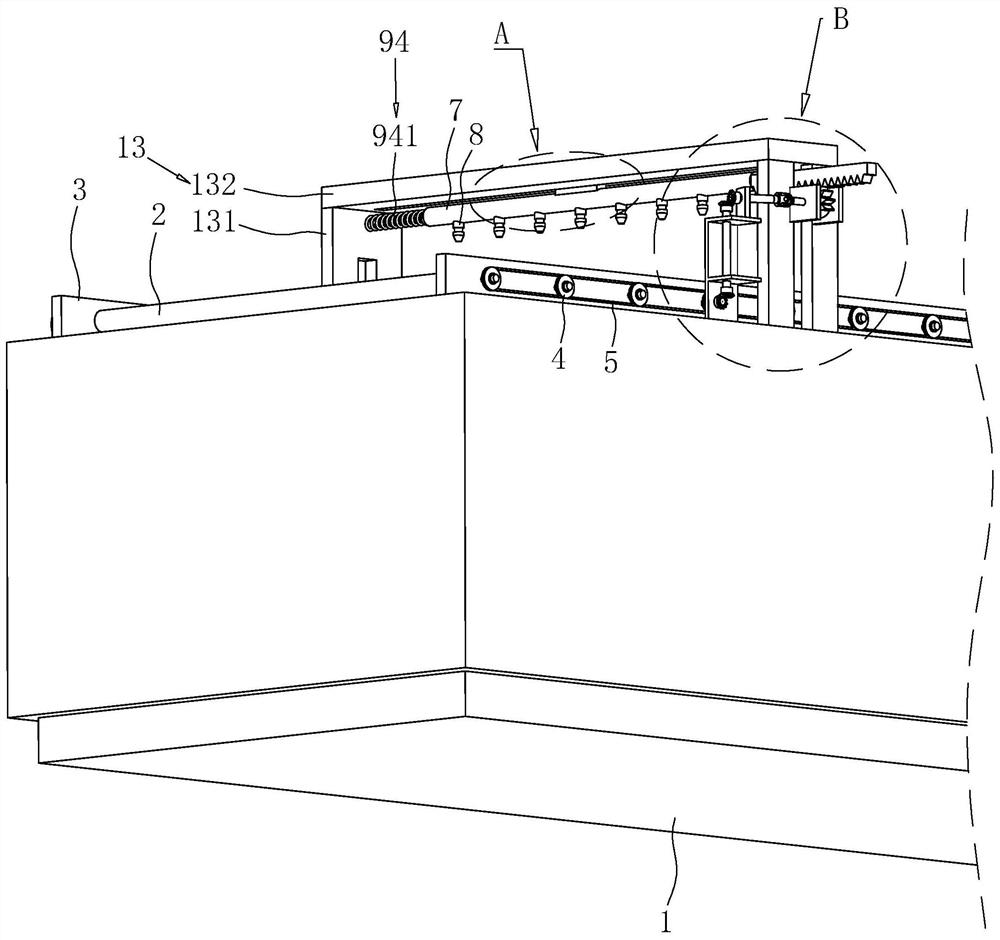

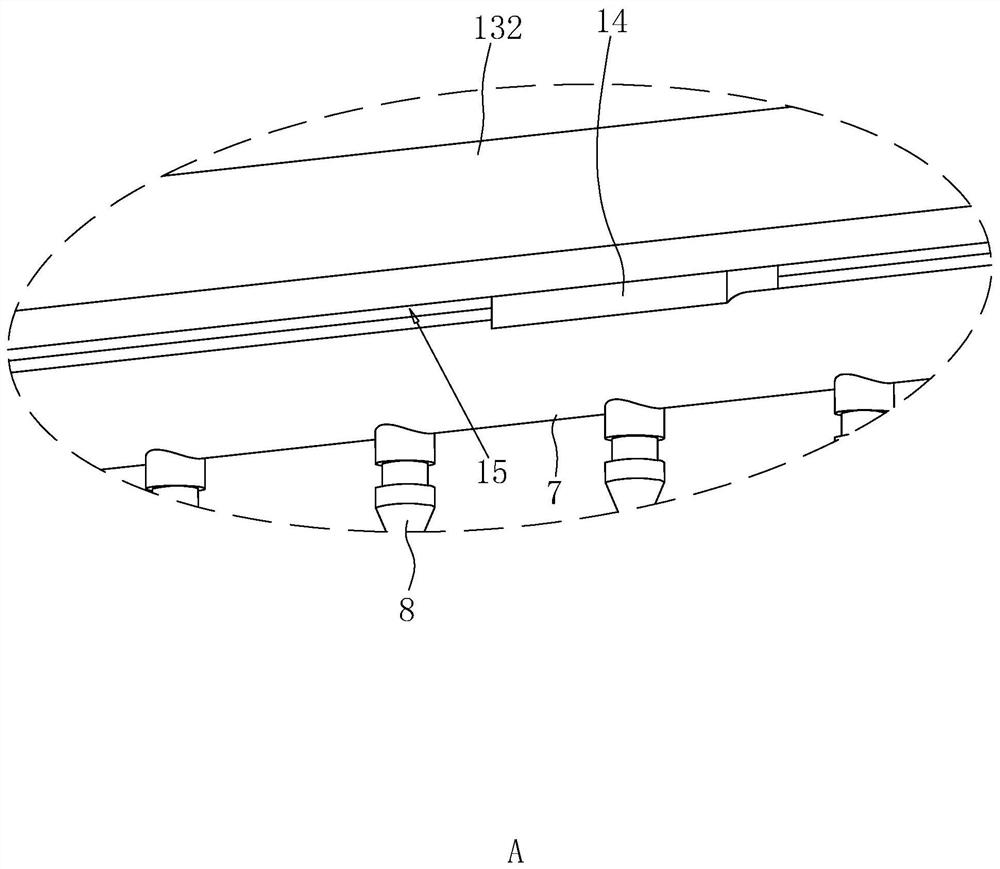

[0038] The following is attached Figure 1-8 The application is described in further detail.

[0039] The embodiment of the present application discloses an aluminum plate painting line. refer to figure 1 , the aluminum plate painting line includes a workbench 1 for spraying the aluminum plate 20. In the present embodiment, the workbench 1 is a cuboid. When the aluminum plate 20 is processed, the aluminum plate 20 is transmitted along the length direction of the workbench 1; the workbench 1 There are a plurality of conveying rollers 2 for conveying the aluminum plate 20 on the top, and the rotation axis of the conveying rollers 2 is perpendicular to the length direction of the workbench 1; in this embodiment, the workbench 1 is provided with two pieces for installing the conveying rollers The first mounting plate 3 of 2, both ends of the conveying roller 2 are rotated and installed on the first mounting plate 3; one end of the conveying roller 2 runs through the first mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com