A wrench multi-group grinding machine for hardware production and preparation

A grinding machine and wrench technology, which is applied in the direction of metal processing equipment, grinding machines, abrasive belt grinding machines, etc., can solve the problems of low grinding efficiency of grinding machines, and achieve the effects of improving grinding efficiency, increasing grinding area, and reducing blank areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

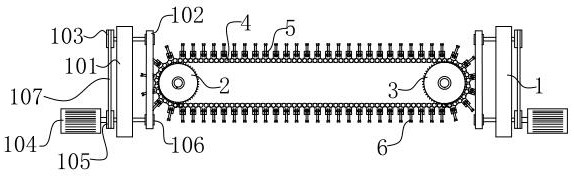

[0039] see figure 1 as well as Figure 7-10 , is a structural schematic diagram of a multi-group grinding machine with wrenches for hardware production and preparation, the grinding machine includes: a chain 4 and a grinding device 1, the chain 4 is set as a closed structure, and the inner ring of the chain 4 is provided with a first drive sprocket 2 and The second driving sprocket 3, wherein, any driving sprocket in the first driving sprocket 2 or the second driving sprocket 3 is a driving wheel, the driving chain 4 rotates, and the outer ring of the chain 4 is provided with a wrench evenly distributed to fix Platform 5, a chain sleeve 508 is respectively provided on both sides of the side wall of each wrench fixing platform 5, and the chain sleeve 508 and the wrench fixing platform are arranged as an integral structure, and the end surface of the chain sleeve 508 is provided with a through hole structure. Chain sleeve 508 is installed on the bearing pin of each chain 4, to ...

Embodiment 2

[0047] see Figure 1-10 , is a structural schematic diagram of a wrench multi-group grinding machine for hardware production and preparation. This embodiment has the same content as the above-mentioned embodiment 1, and the same will not be described in this embodiment. The specific differences are:

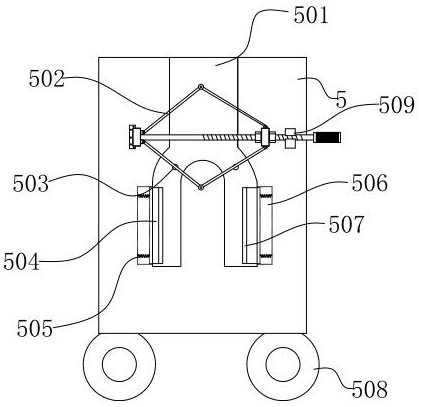

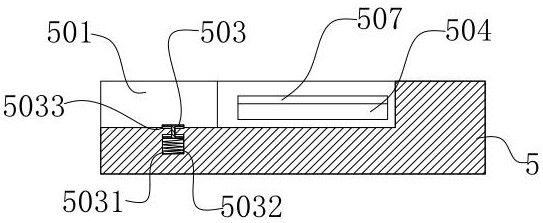

[0048] The wrench fixed table 5 is made as a square block structure, and the top surface of the wrench fixed table 5 is provided with a positioning groove 501, and a side edge of the positioning groove 501 is equipped with a deck 509, and the top surface of the wrench fixed table 5 is located at both sides of the positioning groove 501 Locking device 502 is installed, and the profile of locating groove 501 is made as the same with the profile of wrench 6 ends, and the bottom surface of locating groove 501 is equipped with spring head 503, and the both sides of locating groove 501 are respectively provided with a groove 506, groove 506 is set as a square groove, and a clamping blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com