Brush hair dyeing device for brush preparation

A dyeing device and bristle technology, which is applied in the direction of bristles, brushes, applications, etc., can solve the problems of low efficiency and manpower consumption, and achieve the effects of convenient operation, stable operation of the device, and avoiding the effect of fuel particles sinking to the bottom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

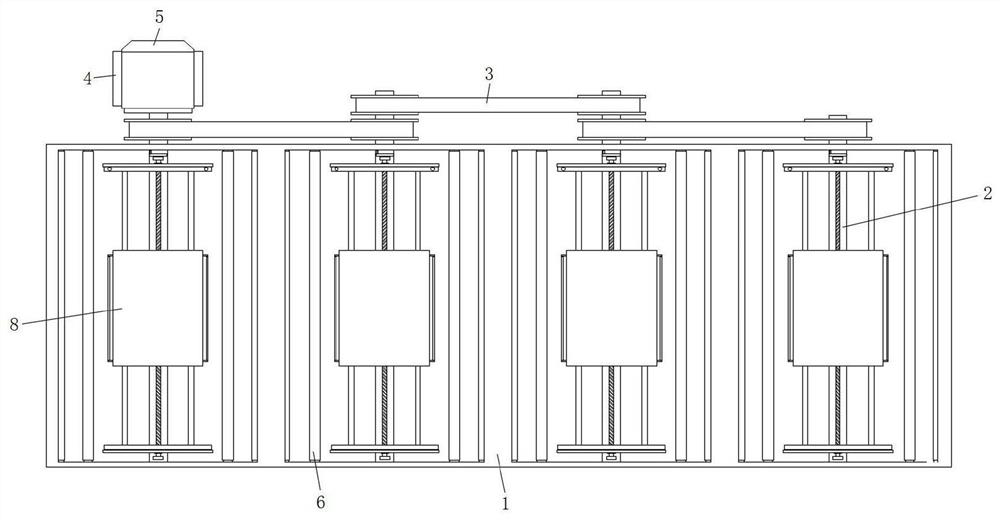

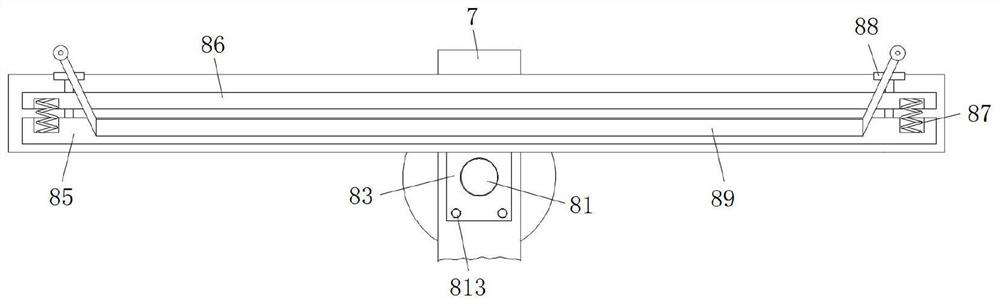

[0029] refer to Figure 1-4 , a bristle dyeing device for brush preparation, comprising a dyeing box 1, the inner wall of the front and rear ends of the upper side of the dyeing box 1 is rotatably connected with a turning rod 2, and the rear ends of two adjacent turning bars 2 are extended to the dyeing box 1 The outer side is connected with a conveyor belt 3 in rotation, and a fixing seat 4 is arranged on one side of the rear end of the dyeing box body 1. The top surface of the fixing seat 4 is fixed with a servo motor 5 through screws, and the output end of the servo motor 5 is fixed to one of the turning rods 2. Connection, the heating pipe 6 is also fixed on the front and rear sides of the bottom of the dyeing box body 1, the vertical plate 7 is fixed on the front and rear ends of the turning rod 2, and the bristle fixing assembly 8 is installed between the two vertical plates 7 on the upper and lower sides, and the bristle fixing assembly 8 Including screw one 81 and scre...

Embodiment 2

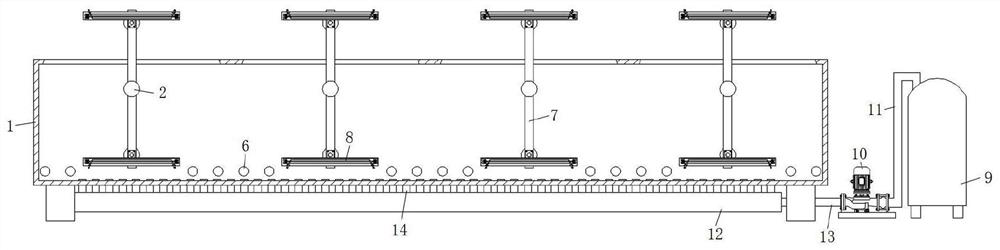

[0031] Such as figure 1 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the paint tumbling assembly includes a gas heater 9 and a booster pump 10, and an air guide tube is fixedly connected between the input end of the booster pump 10 and the output end of the gas heater 9 11. The side of the booster pump 10 close to the dyeing box 1 is also provided with a distributing pan 12, and a gas injection pipe 13 is connected between the side of the gas distributing pan 12 and the output end of the booster pump 10. The upper end of the gas distributing pan 12 is connected to the dyeing Air jet pipes 14 are connected through the casings 1 , and check valves are installed on the inner walls of the air jet pipes 14 .

[0032]Both the gas heater 9 and the booster pump 10 are fixed on the working surface by screws, both sides of the gas separator 12 are fixed on the support at the bottom of the dyeing box 1, and there are multiple gas injection pipes 14 arrange...

Embodiment 3

[0035] Such as figure 1 and 2 As shown, this embodiment is basically the same as Embodiment 1. Preferably, there are multiple overturning levers 2 that are evenly distributed in a row on the upper side of the dyeing box 1, and the upper part of the overturning lever 2 is on the top surface of the dyeing box 1. There are refueling holes on the top.

[0036] In this embodiment, there are multiple turning bars 2, so as to realize batch dyeing of bristles, thereby greatly improving the efficiency of bristle dyeing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com