Magnetic coupler with electromagnetic slip damping

A technology of magnetic coupling and slip, applied in electric brake/clutch, permanent magnetic clutch/brake, asynchronous induction clutch/brake, etc., can solve the problem that magnetic coupling cannot satisfy soft start and high efficiency at the same time, Achieve the effect of light weight, high efficiency and high utilization rate of magnetic steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

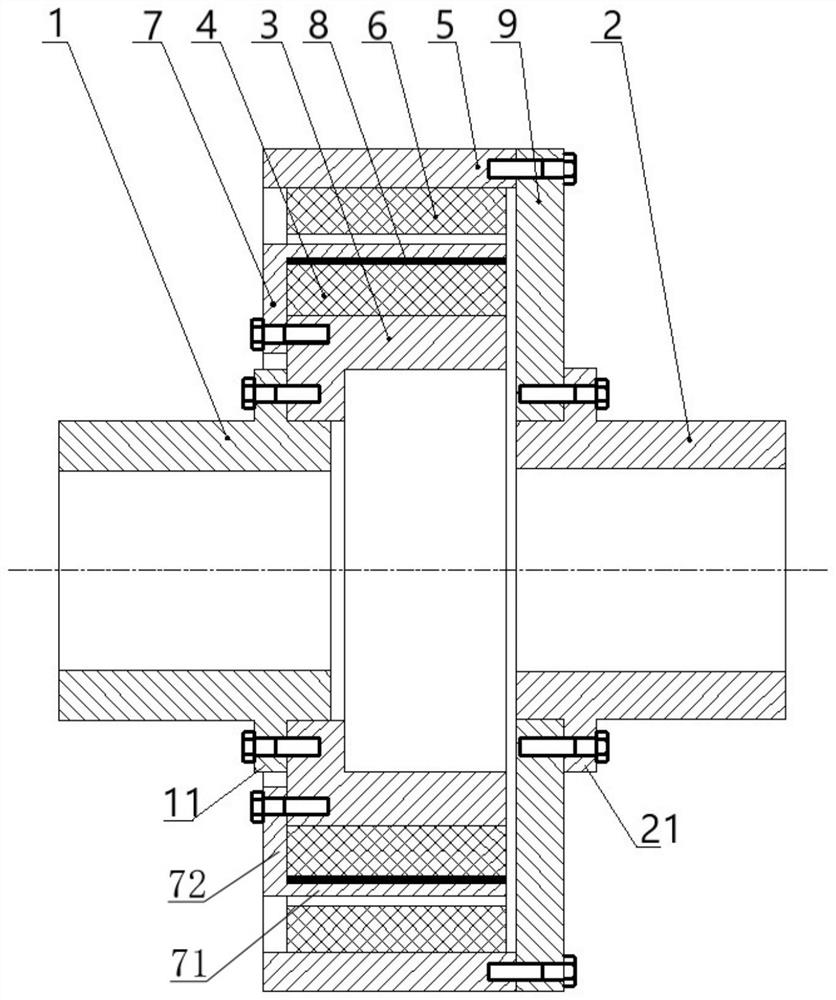

[0040] refer to figure 1 , a magnetic coupling with electromagnetic slip damping provided by the present invention, comprising:

[0041] The first connecting shaft 1 is suitable for connecting with the driving end;

[0042] The second connecting shaft 2 is adapted to be connected to the load end, the second connecting shaft 2 is coaxial with the first connecting shaft 1 and independently arranged;

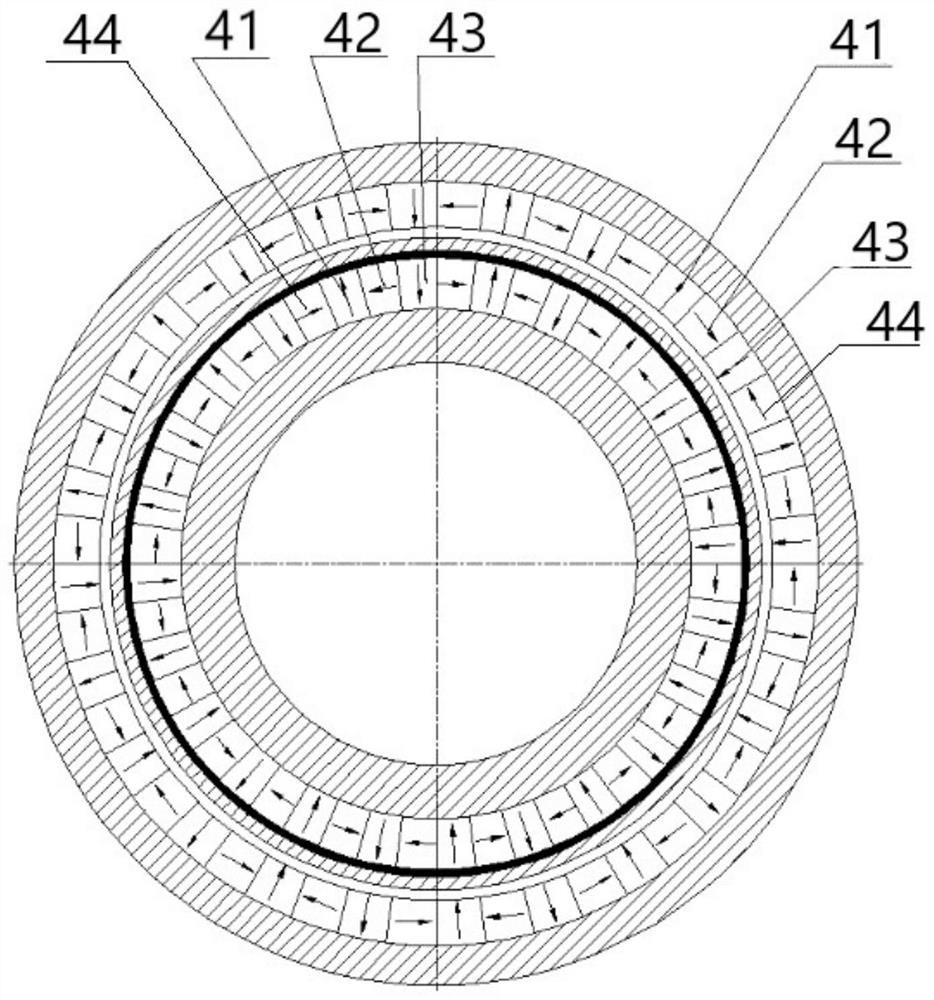

[0043] The inner permanent magnet carrier 3 is coaxially fixed on the first connecting shaft 1, and the inner permanent magnet 4 is fixed on the outer peripheral surface of the inner permanent magnet carrier 3;

[0044] The outer permanent magnet carrier 5 is coaxially fixed on the second connecting shaft 2. The outer permanent magnet carrier 5 is a cylindrical structure and is sleeved on the outside of the inner permanent magnet carrier 3. The inner wall of the outer permanent magnet carrier 5 is fixed with An outer permanent magnet 6, leaving a gap between the outer permanent m...

Embodiment 2

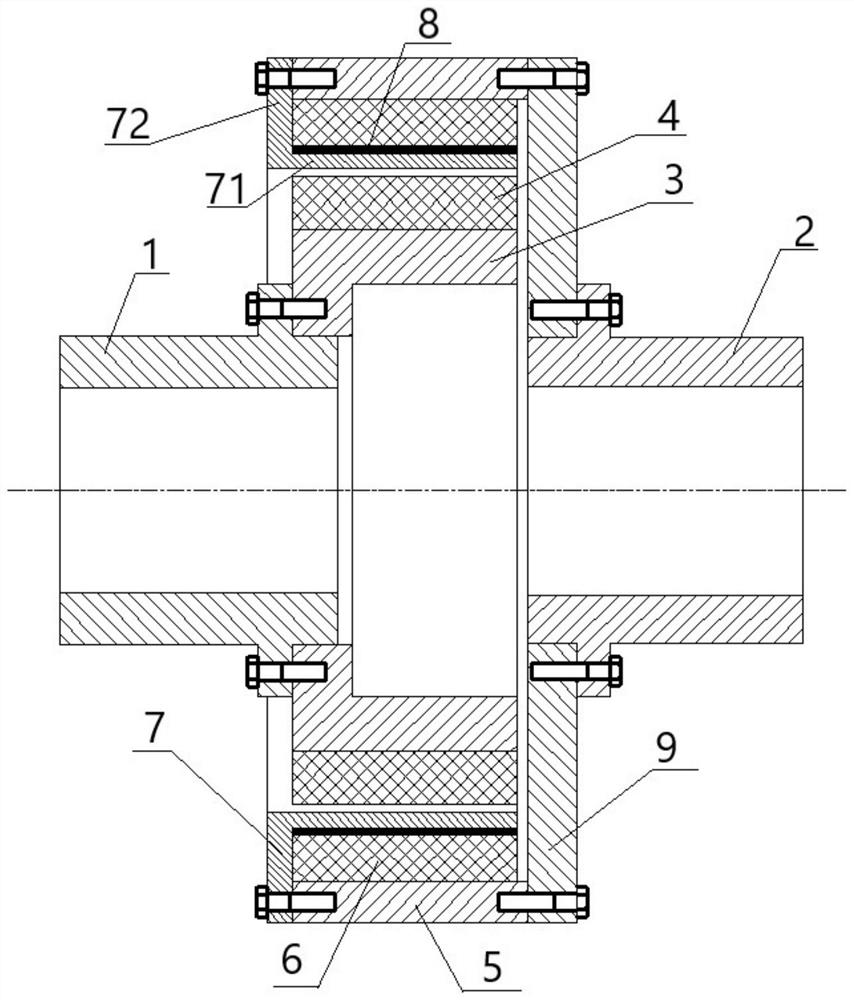

[0072] refer to figure 2 , a magnetic coupling with electromagnetic slip damping provided in this embodiment differs from Implementation 1 only in that:

[0073] In this embodiment, the conductor ring 7 is relatively fixed on the outer permanent magnet carrier 5 , and the heat insulating ring 8 is located between the conductor ring 7 and the outer permanent magnet 6 .

[0074] In other embodiments, the conductor ring 7 can also be fixed on the second connecting shaft 2 through a common connecting structure.

[0075] It is worth noting that no matter whether the conductor ring 7 is fixed relative to the inner permanent magnet 4 or relative to the outer permanent magnet 6, since the inner permanent magnet 4 and the outer permanent magnet 6 have relative rotation, the conductor ring 7 should be connected to another permanent magnet. Leave a gap between them to avoid interfering with the rotation. E.g figure 2 The middle conductor ring 7 is fixed on the outer permanent magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com