Herbage bale drying system

A drying system and straw bale technology, which is applied in the field of straw drying system, can solve the problems of harvest failure, low water content of pasture, easy fall of flowers and leaves of pasture, etc., so as to avoid mildew, ensure system safety, Guarantee the effect of drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to make the embodiments, technical solutions and advantages of the present invention more obvious, the technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Obviously, the described embodiments are part of the embodiments of the present invention, not all of them. Example. Those skilled in the art should understand that these embodiments are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention.

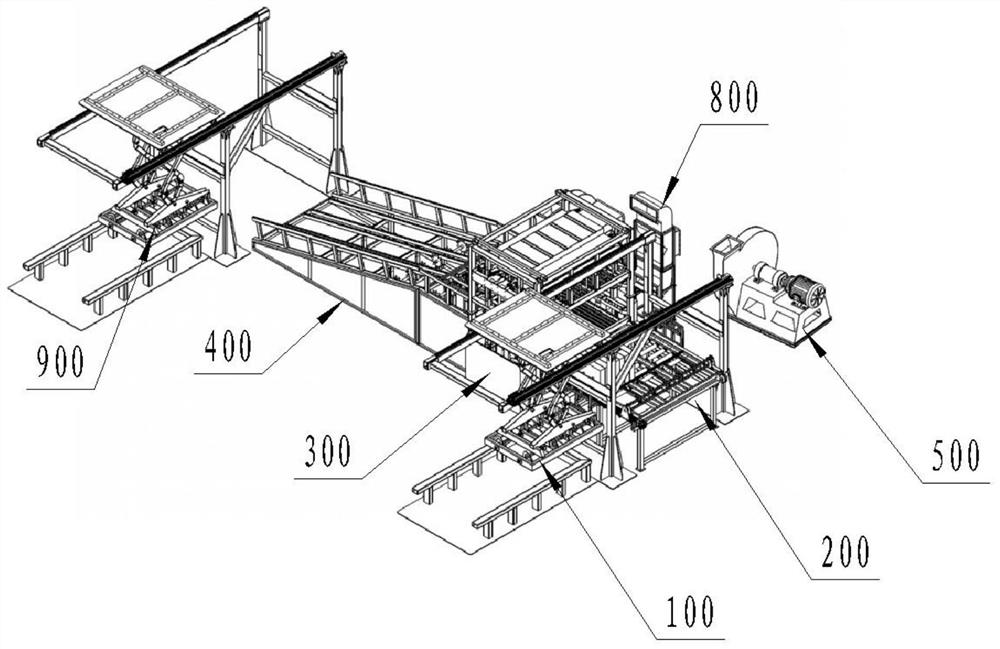

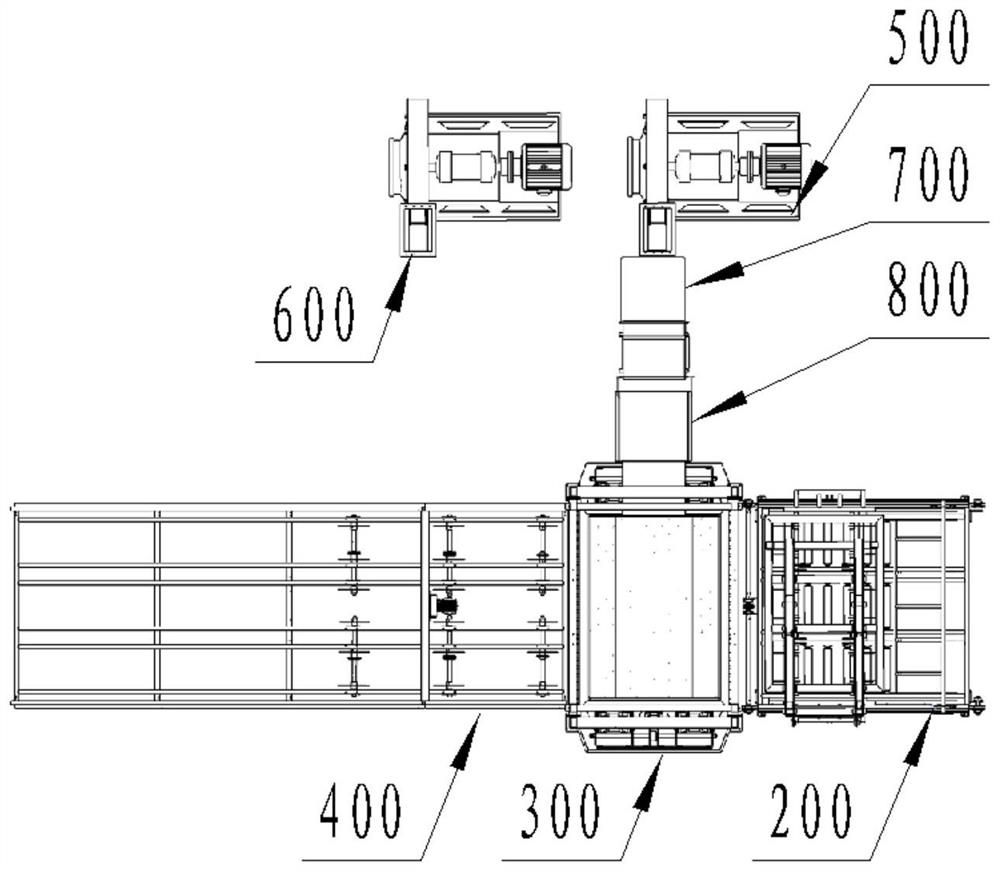

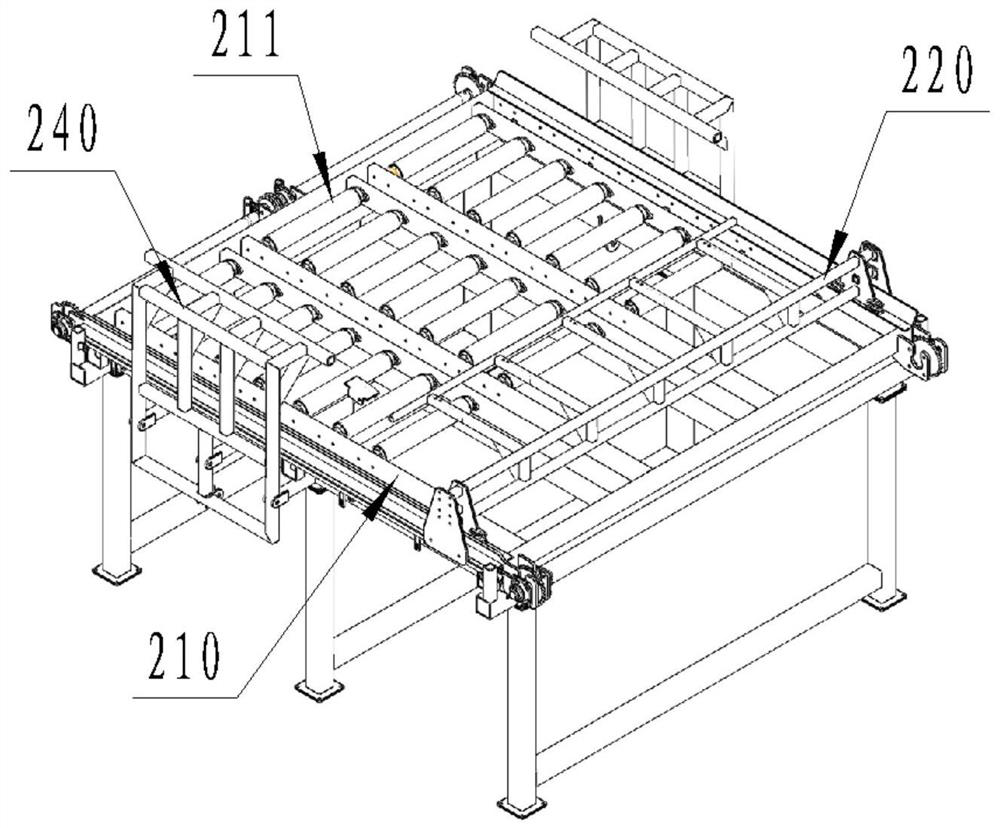

[0062] The first aspect of the present invention provides a bale drying system, including a bale feeding device, a bale drying device, a bale cooling device and a controller, the bale feeding device, the bale drying The device and the bale cooling device are respectively connected to the controller through a communication link; the output end of the bale feeding device is connected to the inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com