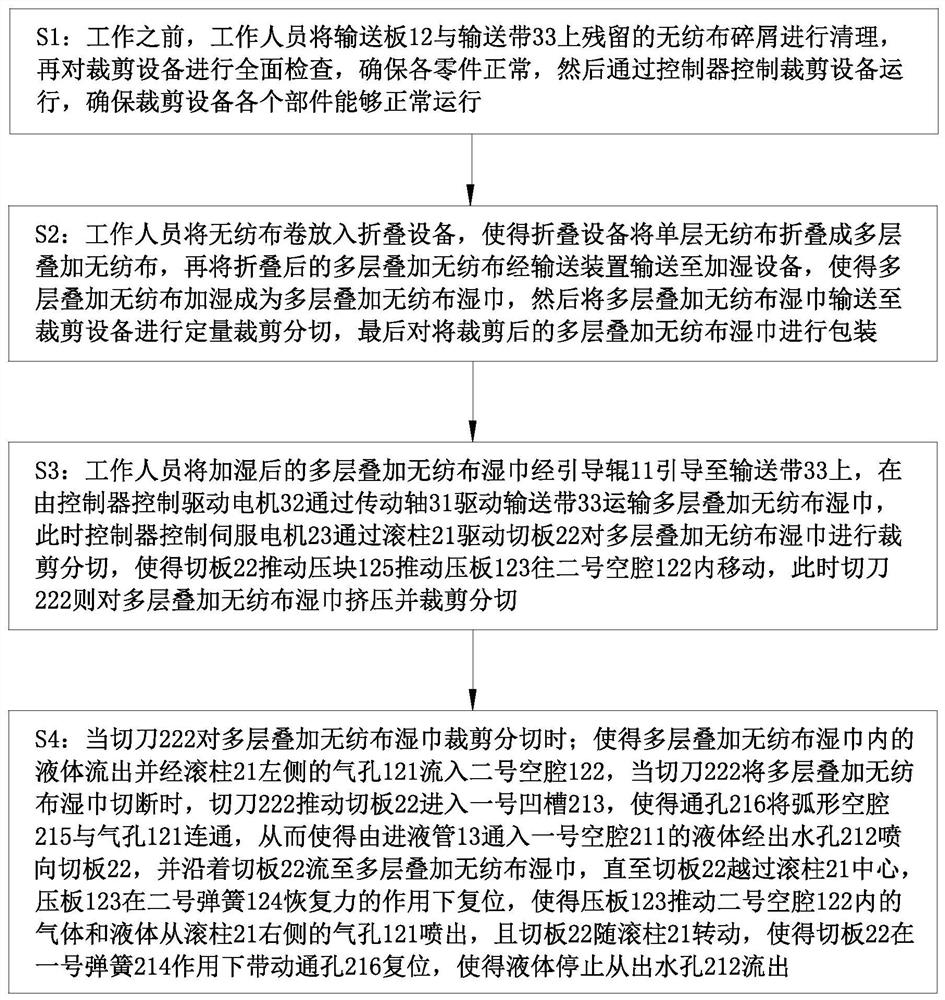

Quantitative cutting equipment and method applied to non-woven fabric wet tissues

A technology for non-woven fabrics and wet wipes is applied in the field of quantitative cutting equipment for non-woven wet wipes, which can solve the problems of low water content of wet wipes, easy drying of wet wipes, and incomplete consideration, so as to improve the use effect and avoid liquid waste. , the effect of improving the application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

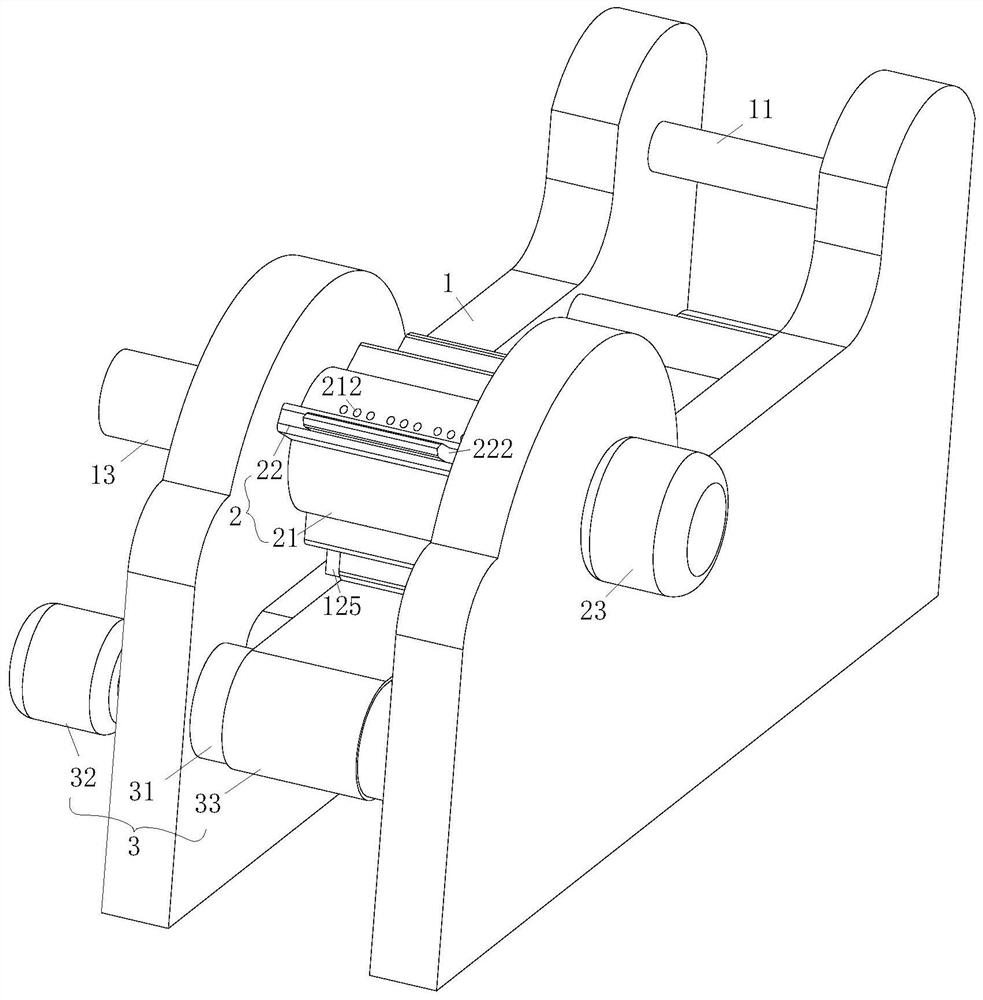

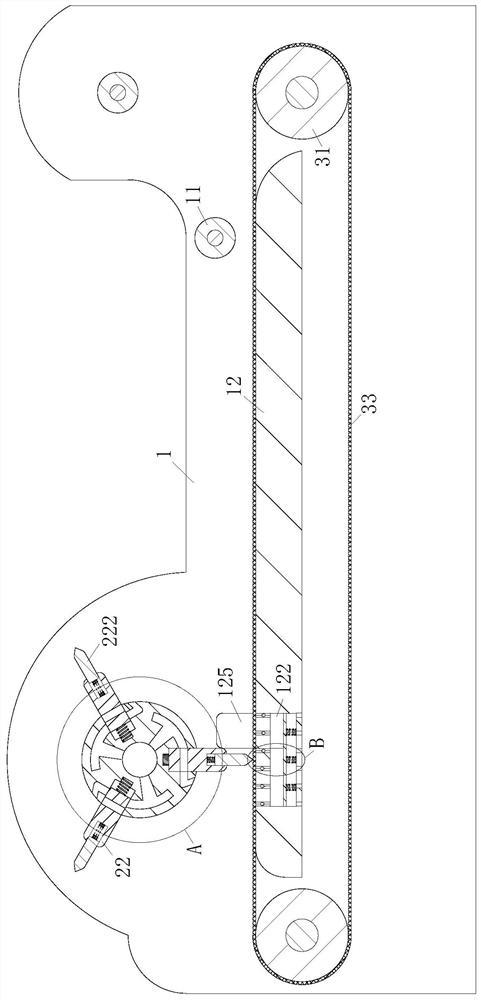

[0035] As an embodiment of the present invention, the outer wall of the roller 21 is provided with a No. 1 groove 213; the cutting plate 22 is slidingly and sealingly connected in the No. The first spring 214 is fixed between them; the roller 21 is provided with an arc-shaped cavity 215; the arc-shaped cavity 215 is used to connect the first groove 213 with the first cavity 211; the water outlet The hole 212 communicates with the No. 1 groove 213; the side wall of the cutting plate 22 is provided with a through hole 216; during work, when the roller 21 drives the cutting plate 22 to cut the non-woven wet tissue, the cutting plate 22 and the multiple The layered non-woven fabric wet wipes contact, and the non-woven fabric wet wipes are cut off. At this time, the cutting plate 22 contacts the conveyor belt 33, so that the conveyor belt 33 blocks the cutting plate 22 under the support of the conveying plate 12, so that the cutting plate 22 is in contact with the conveyor belt 33. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com