Ink binder as well as preparation method and application thereof

An ink binder and oil-soluble technology, applied in the printing field, can solve problems such as gelation and unusable printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

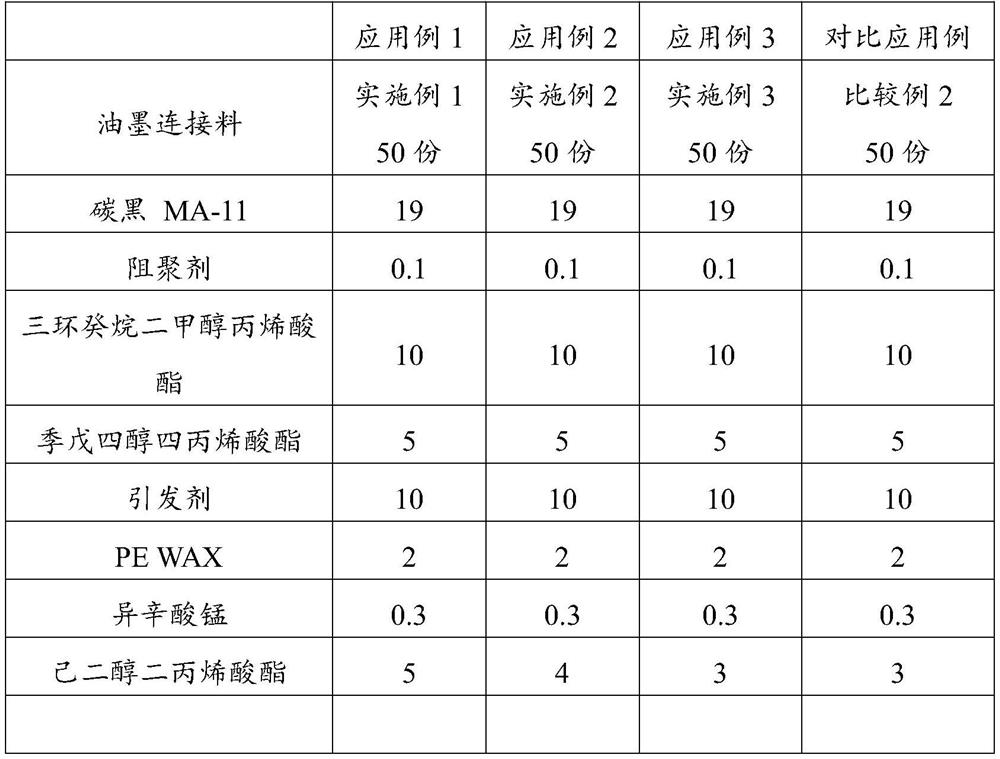

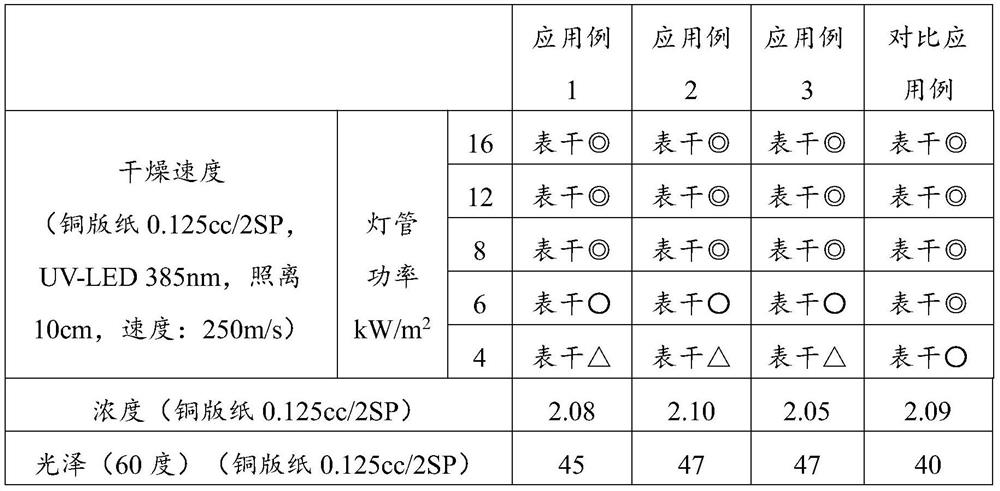

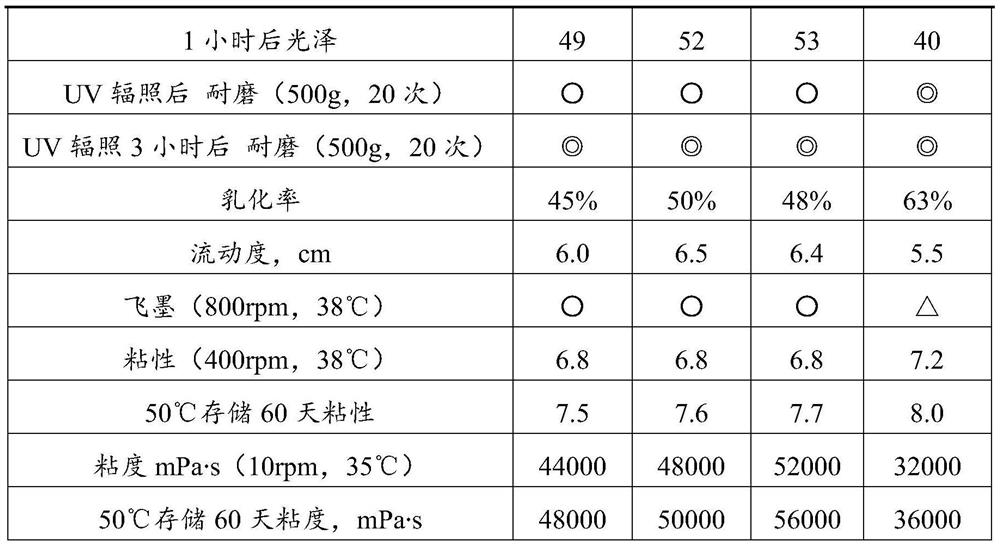

Examples

Embodiment 1

[0050] In a four-neck flask equipped with a stirrer and a thermometer, put 100 parts by weight of isophorone diisocyanate and 0.1 part by weight of TBHQ, heat it in a water bath to 60 ° C, and then slowly add 50 parts by weight of hydroxyethyl acrylate dropwise within 2 hours After the dropwise addition, keep warm for 1 hour. When the measured hydroxyl value is less than 10, lower the temperature to below 40°C to obtain a composite of hydroxyethyl acrylate and diisocyanate.

[0051] In parts by weight, 150 parts of rosin modified phenolic resin (HR-311 produced by Wuhualin, weight average molecular weight 50000, acid value 16) and rosin pentaerythritol ester (ARAKAWAPENCEL GA- 100A, softening point 103°C, acid value 18) 60 parts, C9 petroleum resin (GRAYVALLEY Wingtack Plus, softening point 100°C) 100 parts, linseed oil 200 parts, methyl soyate 50 parts, AF-6 mineral oil 40 parts, heating To 247°C, keep it warm for 1 hour, then lower the temperature to 120°C, add 0.1 part of a...

Embodiment 2

[0053]In parts by weight, 160 parts of rosin modified phenolic resin (HARIMAH532, weight average molecular weight 45000, acid value 21) components, C9 petroleum resin (GRAYVALLEY WingtackPlus, softening point 100) were dropped into a four-necked flask equipped with agitator and thermometer. ℃) 150 parts, 100 parts of soybean oil, 100 parts of linseed oil, 50 parts of isooctyl soyate, 40 parts of AF-6 mineral oil, heat to 247 ℃, keep warm for 1 hour, then cool down to 120 ℃, add antioxidant 0.1 part of TBHQ, 100 parts of polyester acrylic resin (SARTOMER CN293), 50 parts of pentaerythritol tetraacrylate (SARTOMER SR295NS), 150 parts of epoxy soybean oil modified acrylate (SARTOMER CN111), mixed and dissolved at 120°C for 30 minutes, Then drop 50 parts of ethyl isocyanate methacrylate (SHOWADENKO KarenzMOI) in 30 minutes, continue to insulate at 120 ℃ for 30 minutes after the dropwise addition, measure the content of isocyanate to be less than 0.1%, cool down to below 60 ℃, obtai...

Embodiment 3

[0055] In parts by weight, 150 parts of rosin modified phenolic resin (HR-309 produced by Wuhualin, weight average molecular weight 90000, acid value 16) and rosin pentaerythritol ester (ARAKAWAPENCEL GA-100A, softening point 103°C, acid value 18) 60 parts, poly-α-methylstyrene (GRAYVALLEY Cleartack W-100, softening point 100°C) 100 parts, linseed oil 240 parts, soyate isooctyl 50 parts, Heat to 233°C, keep it warm for 1 hour, then cool down to 120°C, add 0.1 part of antioxidant TBHQ, 100 parts of polyester acrylic resin (SARTOMER CN293), 50 parts of pentaerythritol tetraacrylate (SARTOMER SR295NS), epoxy soybean oil modified 150 parts of non-toxic acrylate (SARTOMER CN111), mix and dissolve at 120°C for 30 minutes, then add 50 parts of ethyl isocyanate acrylate (SHOWADENKO KarenzAOI) dropwise within 30 minutes, and continue to heat at 120°C for 30 minutes after the addition is completed. Minutes, the content of isocyanate is determined to be less than 0.1%, and the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com