Preparation method of continuous adhesion hydrogel, hydrogel obtained by preparation method and application of hydrogel

A hydrogel, persistent technology, applied in application, surgery, drug delivery, etc., can solve the problem of poor adhesion persistence and durability of hydrogel, limit the continuous application of hydrogel, unstable long-term adhesion and other problems, to achieve rapid high-strength adhesion and repeatable adhesion, improve underwater adhesion ability, and simple and rapid preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Dissolve 20 mg N, N'-methylenebisacrylamide in 1 mL deionized water to prepare a crosslinker solution; dissolve 0.4 g ammonium persulfate in 1 mL deionized water to prepare an initiator solution ;

[0035] (2) Dissolve 3 mL of acrylic acid, 0.3 g of chitosan, and 200 μL of cross-linking agent solution in 10 mL of deionized water, and stir well;

[0036] (3) 0.3 g of tannic acid was dissolved in the solution of step (2), and stirred thoroughly for 10 min to form a precursor solution of the hydrogel matrix;

[0037] (4) Place the precursor solution of the hydrogel matrix in a 50 °C water bath and incubate for 30 min with stirring, add 200 μL of the initiator solution drop by drop, stir quickly and then pour it into the mold, and let it stand at 60 °C to react and form a hydrogel Gel base.

[0038] The repeated adhesion behavior of the hydrogel matrix prepared in the present invention to pigskin was evaluated according to the ASTM F2258 tensile test. figure 1 It was...

Embodiment 2

[0040] (1) Dissolve 20 mg N, N'-methylenebisacrylamide in 1 mL deionized water to prepare a crosslinker solution; dissolve 0.4 g ammonium persulfate in 1 mL deionized water to prepare an initiator solution ;

[0041] (2) Dissolve 3 mL of acrylic acid, 0.3 g of chitosan, and 300 μL of cross-linking agent solution in 10 mL of deionized water, and stir well;

[0042] (3) 0.3 g of tannic acid was dissolved in the solution of step (2), and stirred thoroughly for 10 min to form a precursor solution of the hydrogel matrix;

[0043] (4) Place the precursor solution of the hydrogel matrix in a 50 °C water bath and incubate for 30 min with stirring, add 200 μL of the initiator solution drop by drop, stir quickly and then pour it into the mold, and let it stand at 60 °C to react and form a hydrogel Gel base.

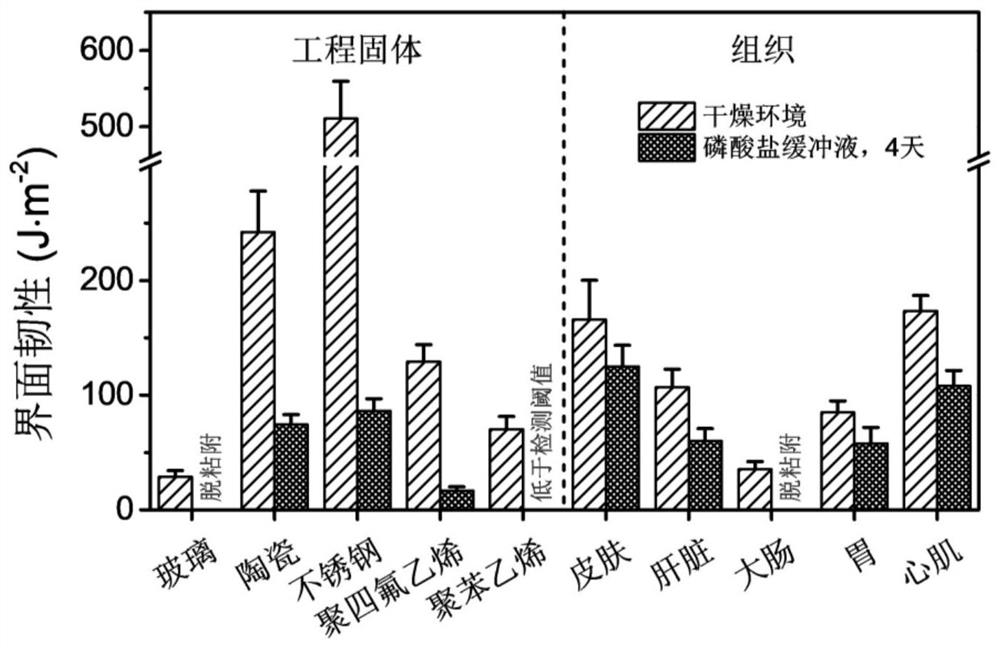

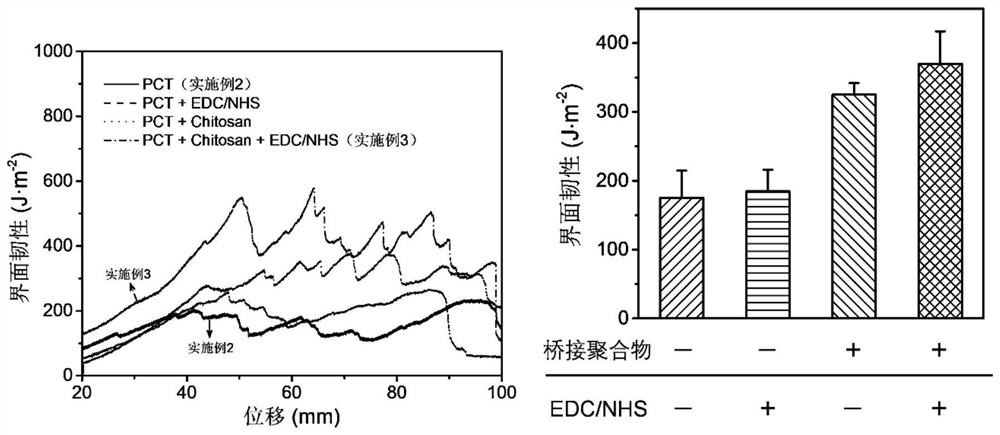

[0044] According to the 180-degree peeling test, the interfacial toughness of the hydrogel matrix prepared in Example 2 of the present invention adhered to different engineering ...

Embodiment 3

[0046] (1) Dissolve 20 mg N, N'-methylenebisacrylamide in 1 mL deionized water to prepare a crosslinker solution; dissolve 0.4 g ammonium persulfate in 1 mL deionized water to prepare an initiator solution ;

[0047] (2) Dissolve 3 mL of acrylic acid, 0.3 g of chitosan, and 300 μL of cross-linking agent solution in 10 mL of deionized water, and stir well;

[0048] (3) 0.3 g of tannic acid was dissolved in the solution of step (2), and stirred thoroughly for 10 min to form a precursor solution of the hydrogel matrix;

[0049] (4) Place the precursor solution of the hydrogel matrix in a 50 °C water bath and incubate for 30 min with stirring, add 200 μL of the initiator solution drop by drop, stir quickly and then pour it into the mold, and let it stand at 60 °C to react and form a hydrogel Gel matrix;

[0050] (5) Dissolve 1.9524 g of 4-morphineethanesulfonic acid (MES) in 100 mL of deionized water to make 0.1 mol / L MES buffer solution, and adjust the pH to 5 with 1 mol / L sodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com