Single-layer plastic sheet object rheological control device without influencing flow velocity

A plastic sheet and control device technology, which is applied in the rheological field of plastic sheet objects, can solve the problems of flow velocity influence, plastic fluid transportation, and difficult flow velocity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

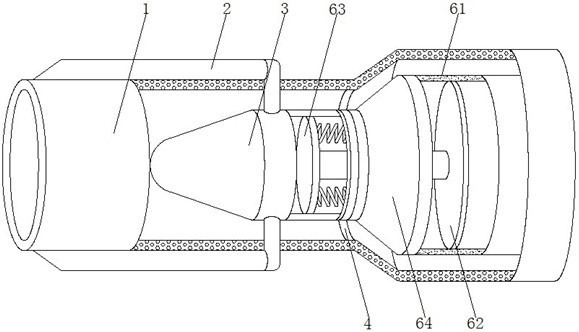

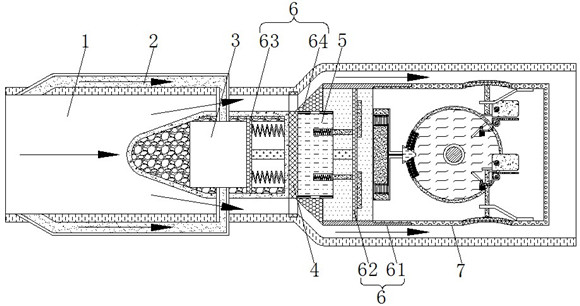

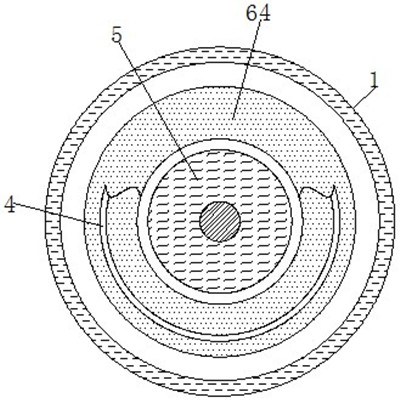

[0027] see Figure 1-5 , a rheological control device for a single-layer plastic sheet object that does not affect the flow rate, comprising a flow tube 1 for transporting plastic fluids, the surface of the flow tube 1 is opened with a side branch 2, and the side branch 2 is connected to the inside of the flow tube 1 The end away from the flow tube 1 communicates with the inside of the pressure chamber 3, and is used to make the pressure inside the pressure chamber 3 the same as the pressure inside the flow tube 1. The inside of the flow tube 1 is fixedly connected with the pressure chamber 3, and the pressure chamber 3 The surface is fixedly connected with the flow transfer plate 4 , and the surface of the flow transfer plate 4 is provided with an annular notch, which cooperates with the adjustment cone 64 to adjust the size of the flow channel inside the flow tube 1 .

[0028] The surface of the flow transfer plate 4 is fixedly connected with a sliding seat 5 for adjusting t...

Embodiment 2

[0031] see Figure 1-5 , a single-layer plastic sheet object rheological control device that does not affect the flow rate, including a flow tube 1 for transporting plastic fluid, the inside of the flow tube 1 is fixedly connected with a fixed ring 7, and the fixed ring 7 and the adjustment cylinder 61 There is a sliding connection between them, and the inside of the fixed ring 7 is provided with a temperature control mechanism 8, which is used to adjust the position of the resistance ring 11 according to the temperature inside the plastic fluid. The outer surface of the tube is located inside the flow tube 1, and is used to drive the power column 82 to move through thermal deformation.

[0032] The surface of the heat-sensitive metal sheet 81 is provided with a power column 82, and the lower end of the power column 82 is adapted to the side surface of the rotary block 83 to limit the rotation of the rotary block 83. The side of the power column 82 is provided with a rotary bl...

Embodiment 3

[0036] see Figure 1-5 , a rheological control device for a single-layer plastic sheet object that does not affect the flow rate, comprising a flow tube 1 for transporting plastic fluids, the surface of the flow tube 1 is opened with a side branch 2, and the side branch 2 is connected to the inside of the flow tube 1 The end away from the flow tube 1 communicates with the inside of the pressure chamber 3, and is used to make the pressure inside the pressure chamber 3 the same as the pressure inside the flow tube 1. The inside of the flow tube 1 is fixedly connected with the pressure chamber 3, and the pressure chamber 3 The surface of the flow transfer plate 4 is fixedly connected, and the surface of the flow transfer plate 4 is provided with an annular notch, which cooperates with the adjustment cone 64 to adjust the size of the flow channel inside the flow tube 1. The surface of the flow transfer plate 4 is fixedly connected with a sliding seat 5, used to adjust the movement o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com