Electric-melted pipeline press-fitting process, press-fitting tool and press-fitting tool manufacturing process

A technology of press-fitting tools and electric fusion pipe fittings, which is applied in the field of installation technology, can solve the problems of heavy pipe weight, failure to meet leak-proof requirements, and difficult assembly, and achieve high assembly efficiency, simple press-fitting devices, and high-quality welds. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

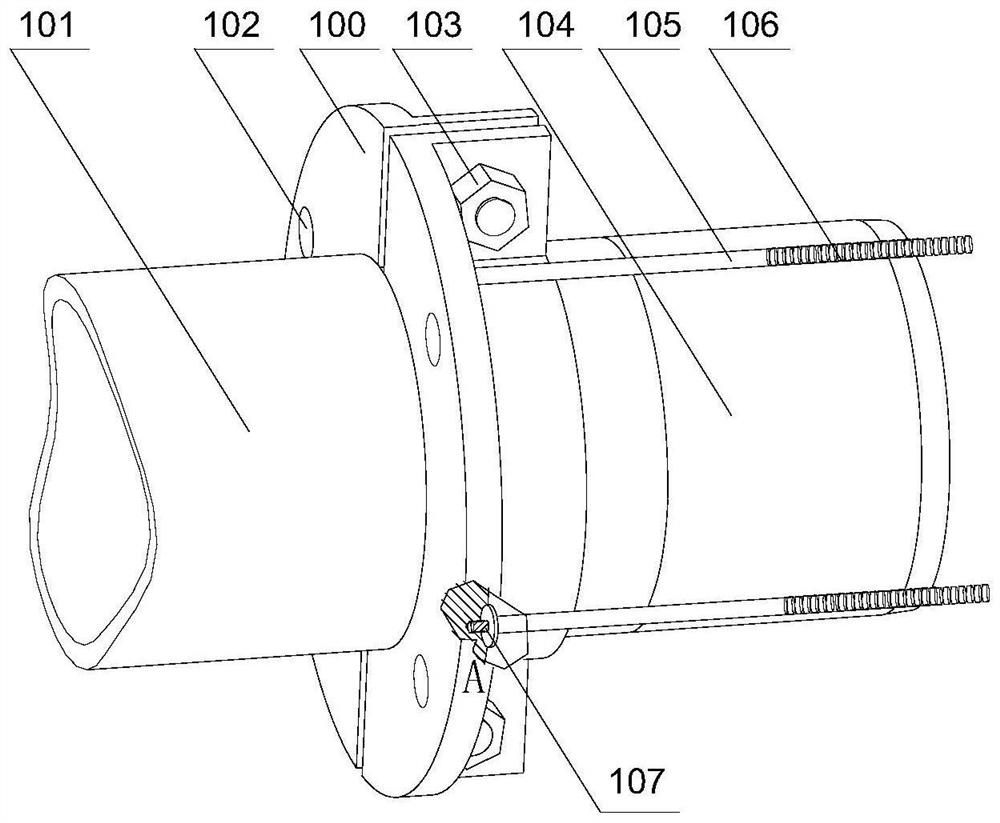

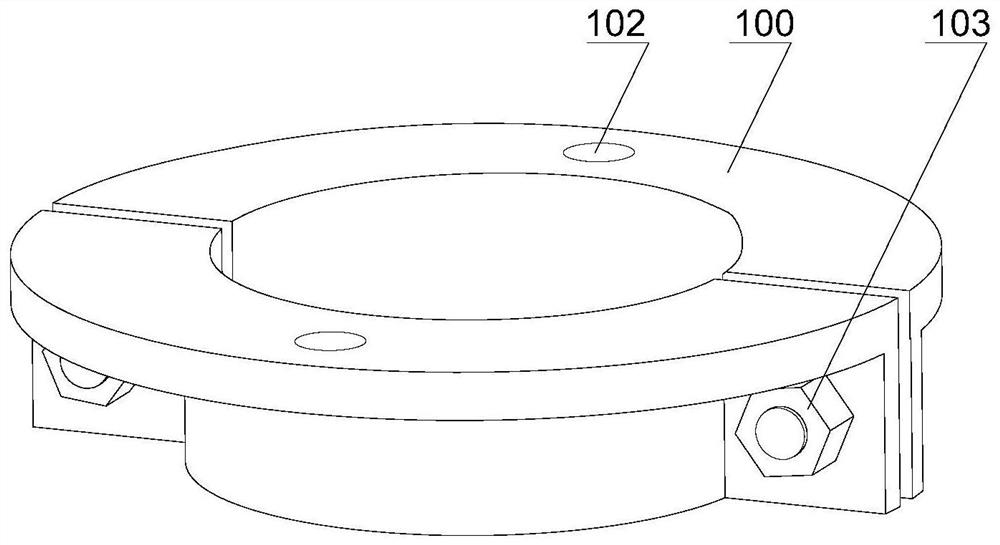

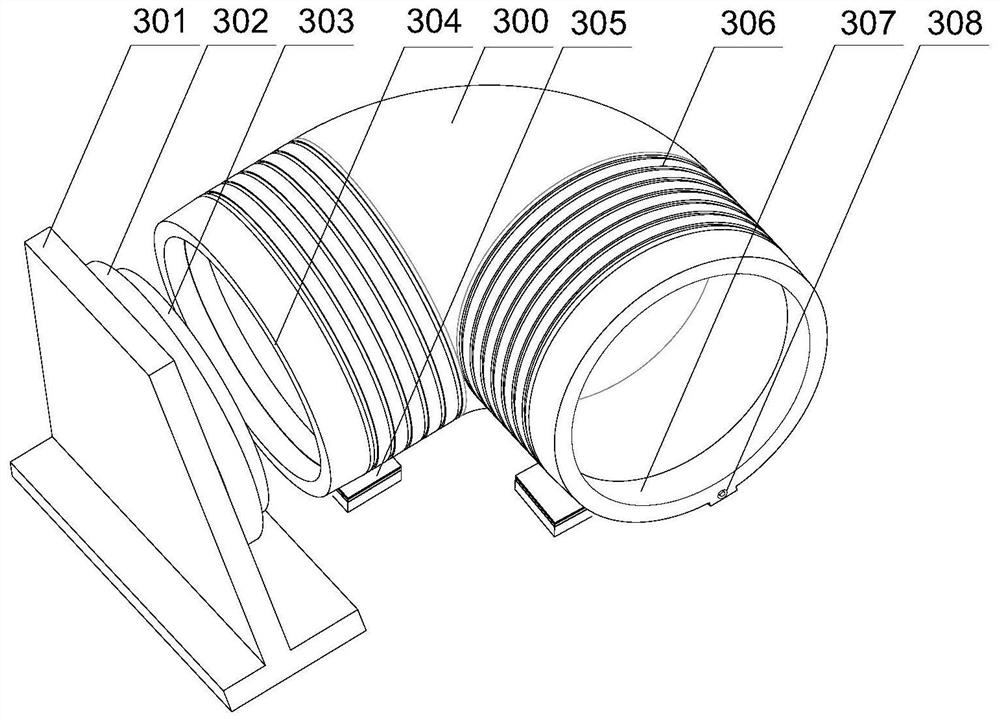

[0081] Prior to this, in order to deepen the understanding of the present invention, this embodiment first further elaborates on the way of installing pipelines in the prior art: the pipeline to be connected is inserted into the socket of the pipe fitting for preliminary plug-in connection, and then connected through The electric plug on the pipe fitting is energized and heated so that the inner surface of the pipe fitting at the socket and the outer surface of the pipe, that is, the plastic near the two-phase contact surface, melts, then the power is turned off, cooled, and then welded together to complete the welding.

[0082] It should be added that: as known to those skilled in the art, when an injection molding machine is produced, the molten plastic begins to cool in a closed container such as a mold under relatively high pressure and gradually solidifies from the surface of the product to the inside of the product. During this process, when the molten plastic in the inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com