A processing method and processing device for new energy vehicle power supply accessories

A technology for new energy vehicles and processing devices, which is applied in metal processing equipment, maintenance and safety accessories, metal processing machinery parts, etc. The effect of deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

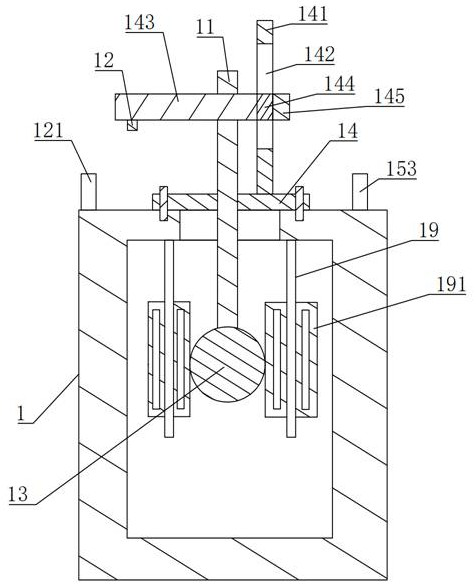

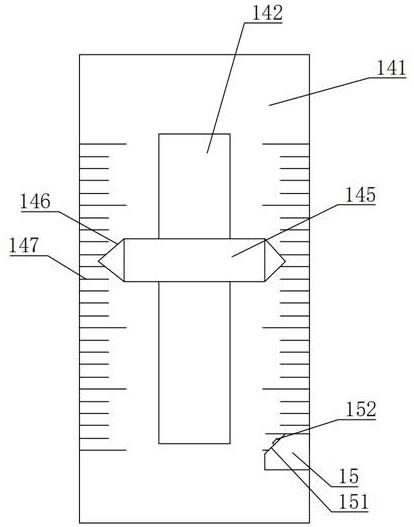

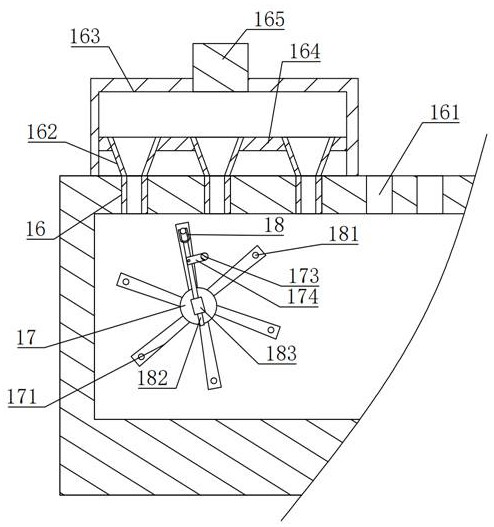

[0025] Embodiment 1: A kind of new energy vehicle power supply accessories processing device, such as figure 1 and figure 2 , including a liquid storage box 1 set on the machine tool and used to store cutting fluid. A detection rod 11 is vertically slidably connected to the wall of the upper end of the liquid storage box 1. One end of the detection rod 11 enters the liquid storage box 1, and the other end Located at the upper end of the liquid storage box 1, and the detection rod 11 is provided with a distance sensor 12 for measuring the distance from the distance sensor 12 to the upper end wall of the liquid storage box 1 at one end extending out of the outer wall of the upper end of the liquid storage box 1, and the outer wall of the upper end of the liquid storage box 1 is provided with There is an alarm light 121 controlled by the distance sensor 12, a floating ball 13 is provided on the side of the detection rod 11 located in the liquid storage box 1, and a limit piece i...

Embodiment 2

[0035] Embodiment 2: A processing method according to the above embodiment 1, including fixing the plate to be processed of the new energy vehicle power box body on the drilling machine through the fixture, and then starting the drilling machine, the cutting fluid is extracted from the liquid storage box 1 and It is poured on the position where the plate to be processed is processed. With the work of the drilling machine, the liquid level of the chip liquid in the liquid storage box 1 gradually decreases, and the floating ball 13 also decreases. When the distance collected by the distance sensor 12 is less than the preset value, the control The warning lamp 121 lights up.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com