Internet of Things intelligent gas meter speed reducer output end movable sealing ring intelligent assembling system

A dynamic sealing ring and assembly system technology, which is applied to the device for coating liquid on the surface, metal processing, metal processing equipment, etc., can solve the inconvenience of applying silicone oil to the dynamic sealing ring, the stable handling of the dynamic sealing ring, and the inconvenience of the dynamic sealing ring Accurate installation and other issues to achieve the effect of improving assembly efficiency and assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

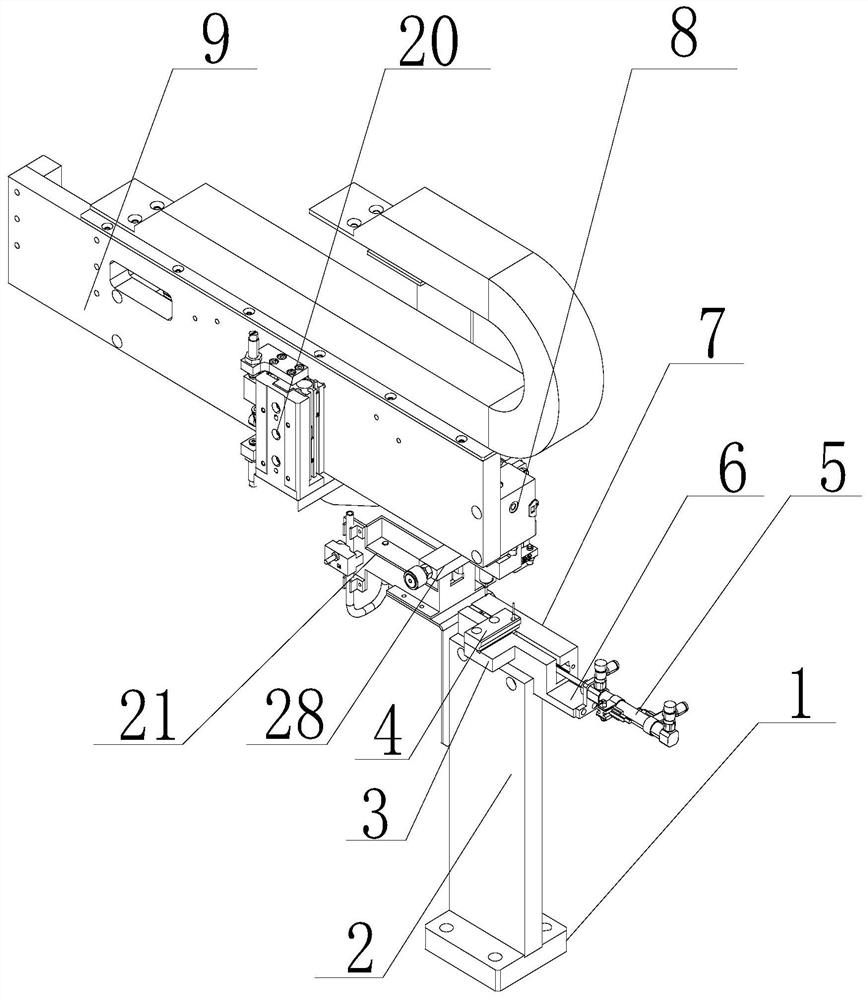

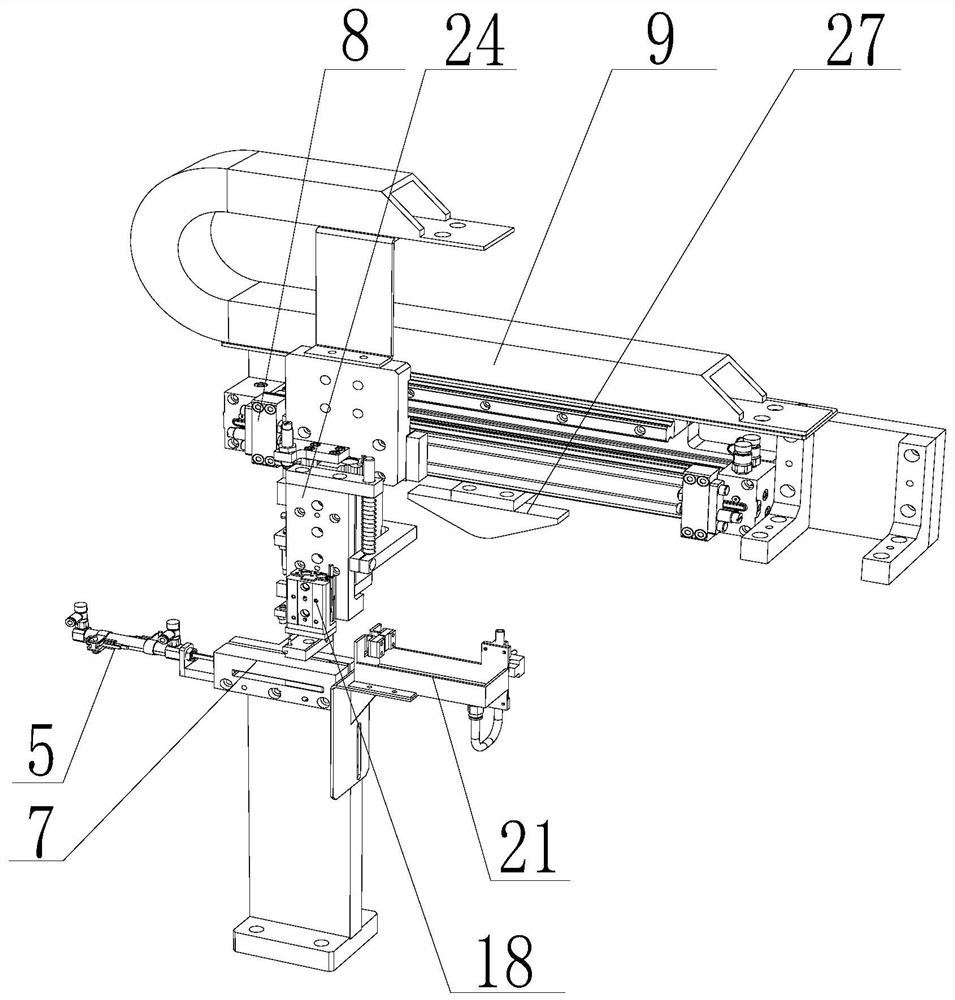

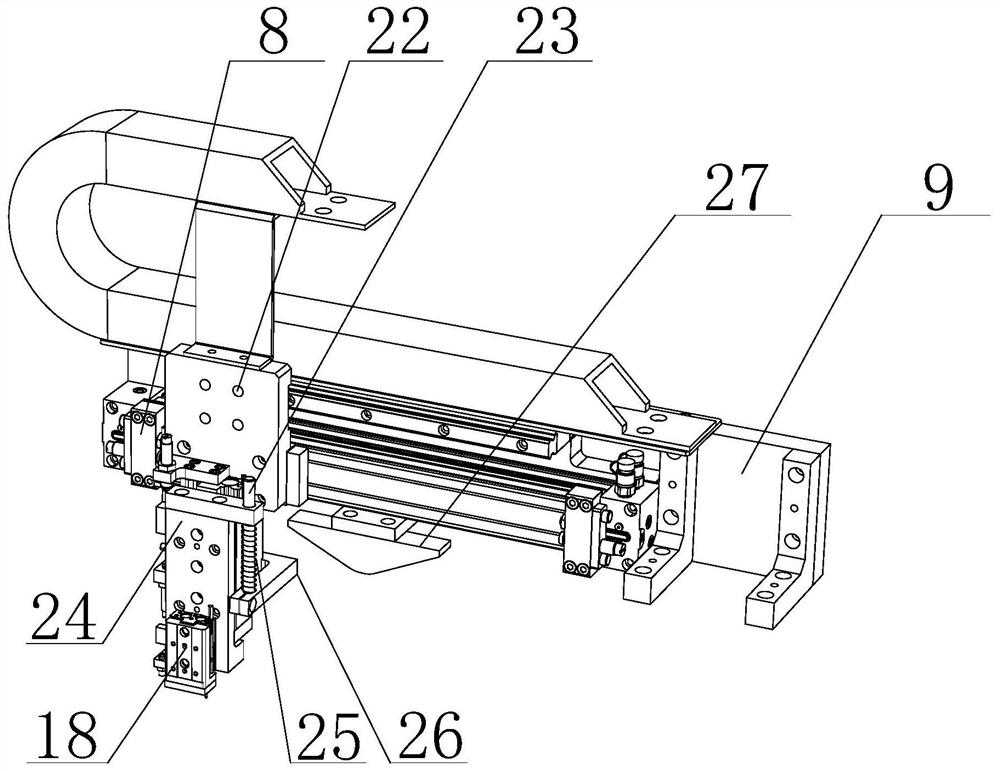

[0052] Such as Figure 1 to Figure 8 As shown, the present invention includes a management platform, a sensor network platform, and a distribution assembly for distributing materials at the feed inlet of the dynamic sealing ring, and an assembly assembly for assembling the dynamic sealing ring is provided on the output end of the distribution assembly , the bottom of the assembly assembly is also provided with a silicone oil pool 21; the assembly assembly includes a transfer mechanism 8, a silicone oil application mechanism, and a retrieving mechanism, and the retrieving mechanism can be used for dynamic sealing on the output end of the distribution assembly The transfer mechanism 8 can drive the retrieving mechanism to move between the output end of the distribution assembly and the assembly line, and when the retrieving mechanism moves back from the assembly line to the output end of the distribution assembly, the silicone oil smearing mechanism can Changing the motion traje...

Embodiment 2

[0056] On the basis of Example 1, the material distribution assembly includes a support element, a material distribution unit and a feed track 3, the material distribution unit is installed on the top of the support unit, and one end of the feed track 3 vibrates with the dynamic sealing ring The disc is connected, and the other end communicates with the distribution unit.

[0057] The dynamic sealing ring in this technical solution uses the vibration of the vibrating plate to transport the dynamic sealing ring in the vibrating plate to the material distribution assembly. The dynamic sealing ring vibrating out of the disk enters the feeding track 3, and then is automatically transported to the material distribution unit for material distribution processing of the dynamic sealing ring.

[0058] Described supporting unit comprises base 1 and the supporting leg 2 that is positioned at the top of base 1, and the top of described supporting leg 2 is connected with the bottom of dist...

Embodiment 3

[0067] On the basis of embodiment 2, the bottom of the silicone oil pool 21 is provided with an L-shaped support plate 36, and one side of the support plate 36 is connected with the bottom of the silicone oil pool 21, and the other side is connected with the side wall of the support leg 2.

[0068] In order to ensure that the silicone oil pool 21 for storing silicone oil can be stably arranged under the assembly assembly, the support plate 36 on the silicone oil pool 21 is connected to the support leg 2; both sides of the silicone oil pool 21 are provided with convex edges, and the convex edges are fixed by bolts On the support plate 36, the silicone oil pool 21 is stably fixed under the assembly assembly.

[0069] The top of the silicone oil pool 21 is provided with two cross-sections that are U-shaped or other first fixing plates 32 such as Z-shaped, I-shaped or integral block structure, etc., wherein the first fixing plate 32 can also be I-shaped, Both the first fixed plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com