Drilling device with drill bit convenient to maintain

A drilling device and drill bit technology, applied in boring/drilling, maintenance and safety accessories, drilling/drilling equipment, etc., can solve the problems of labor consumption and low efficiency, save manufacturing costs, and have a wide range of cooling , to ensure the effect of the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

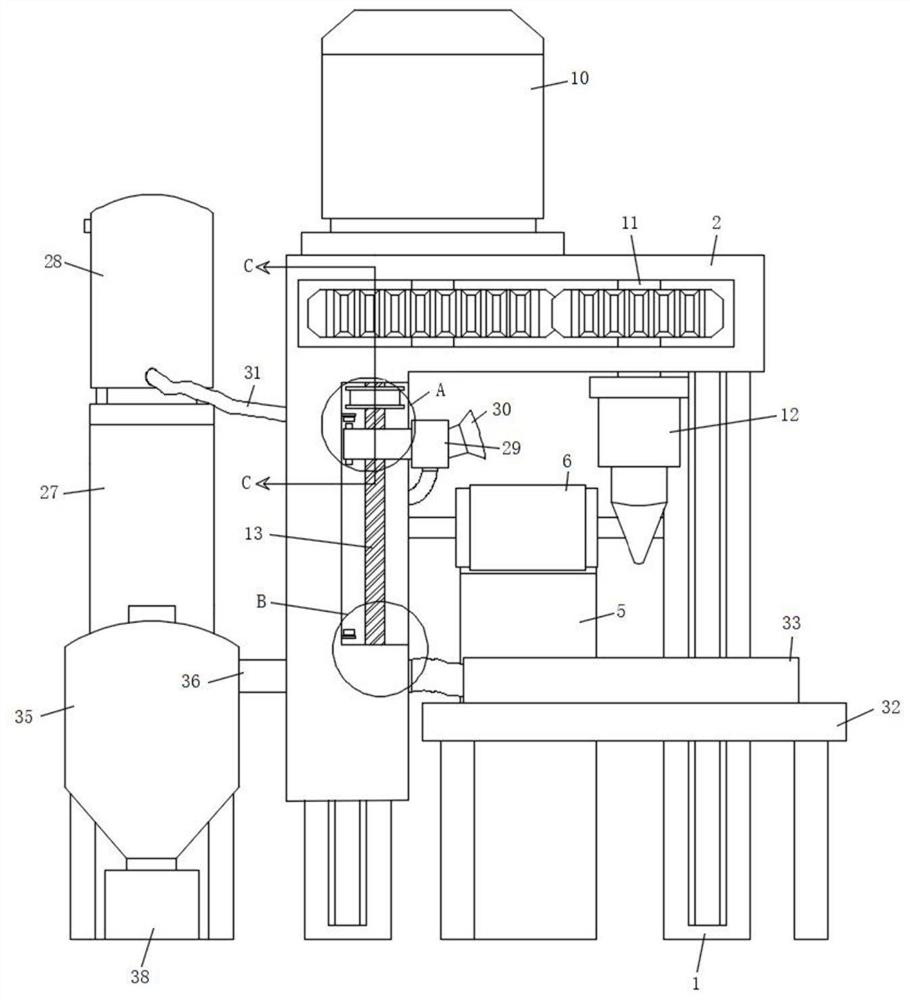

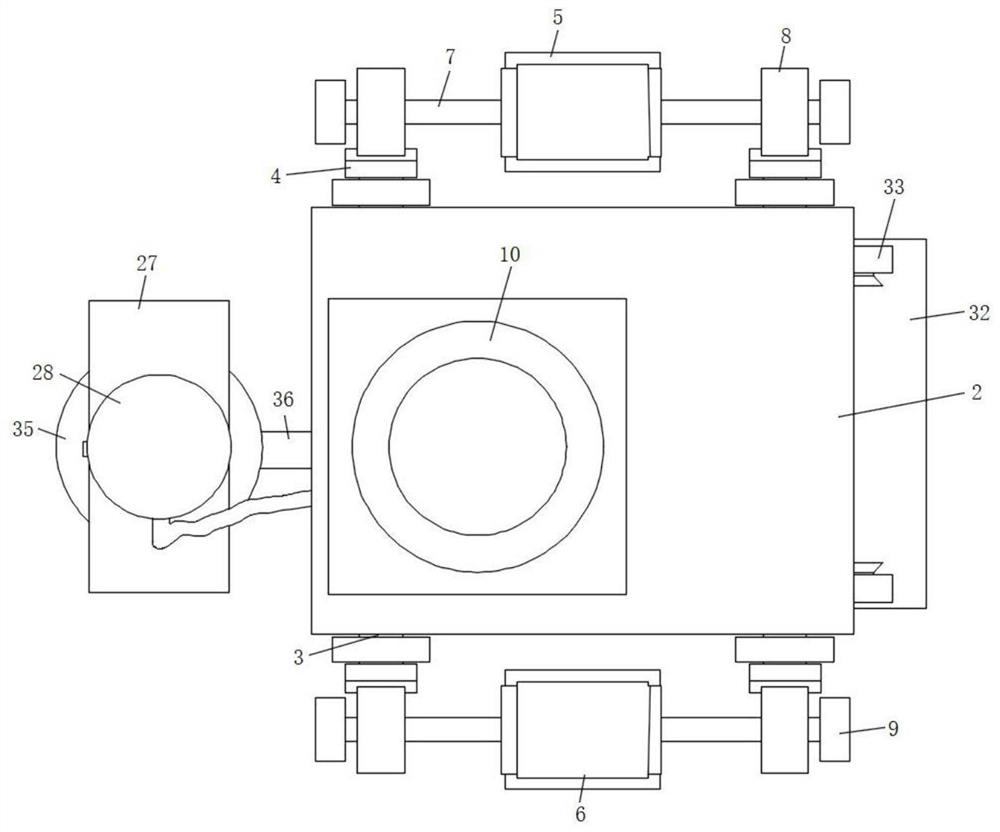

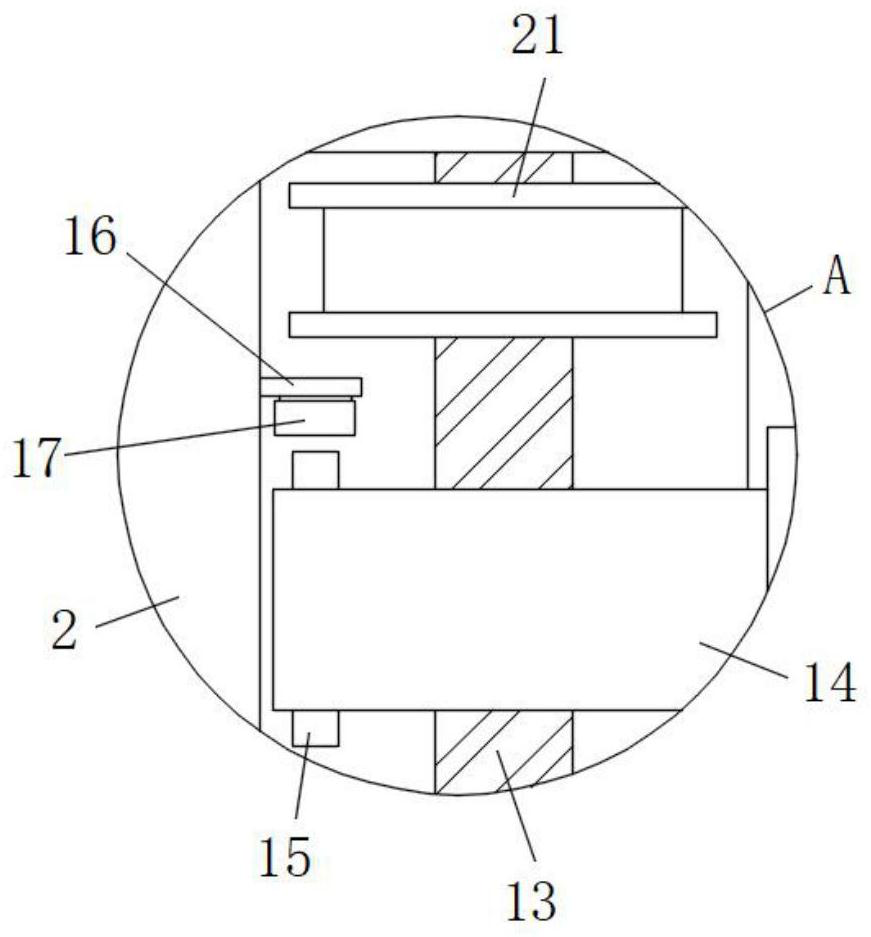

[0030] refer to Figure 1-6, a drilling device for easy maintenance of drill bits, including vertical rails 1, four vertical rails 1 are arranged and fixed on the working surface in a rectangular shape, mounting frames 2 are arranged between the vertical rails 1, and the front and rear ends of the vertical rails 1 are uniform There are slide rails running through, and the inner walls of the slide rails are slidably connected with a mounting block 3, one end of the mounting block 3 is fixedly connected with the mounting frame 2, and the other end of the mounting block 3 extends to the outside of the vertical rail 1 and is fixed with a rack 4 , the front and rear sides of the mounting frame 2 are provided with mounting bases 5, the top surface of the mounting base 5 is fixed with a double-axis motor 6, the output end of the double-axis motor 6 is fixed with a drive rod 7, and the outer wall of the drive rod 7 is fixed with screws There are driving gears 8, and the driving gears ...

Embodiment 2

[0032] like figure 1 , 2 As shown in and 7, this embodiment is basically the same as Embodiment 1. Preferably, the impurity removal assembly includes an adsorption hollow frame 33, an adsorption bucket 34 is installed on the inner wall of the adsorption hollow frame 33, and a cyclone collector is also fixed on the inner wall of the lower side of the working frame 27. 35, between the input end of the cyclone collector 35 and the side wall of the adsorption hollow frame 33, a miscellaneous removal pipe 36 is connected through, and a pump body is installed on the miscellaneous removal pipe 36, and the bottom side of the cyclone collector 35 is connected with a miscellaneous dish 37 by threads .

[0033] A plurality of adsorption buckets 34 are provided and evenly distributed on the inner wall of the adsorption hollow frame 33 , and the impurity removal pipe 36 is slidably connected to the installation frame 2 .

[0034] In this embodiment, the adsorption of gas around the drill...

Embodiment 3

[0036] like figure 2 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the side of the drive gear 8 facing away from the mounting seat 5 is provided with a stabilizing seat 9, and one end of the driving rod 7 is rotatably connected to the side wall of the stabilizing seat 9.

[0037] In this embodiment, one end of the driving rod 7 is rotatably connected with a stable seat 9, so that the device rotates more smoothly when the driving rod 7 is driven.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com