A prefabricated steel mesh processing equipment

A processing equipment and steel mesh technology, applied to wire processing, wire mesh, household appliances, etc., can solve the problems of lack of horizontal steel and longitudinal steel fastening, lower quality of steel mesh, easy deformation, etc., to achieve simple structure , reduce the impact, improve the quality of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

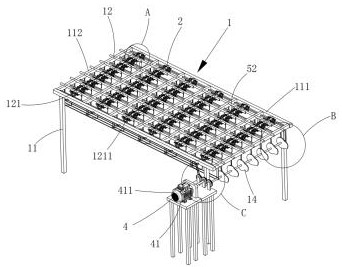

[0039] like figure 1 As shown, a prefabricated steel mesh processing equipment includes:

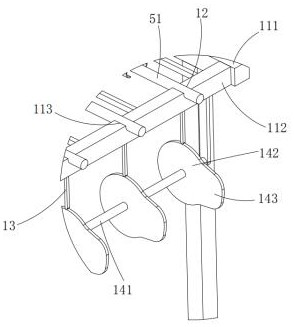

[0040] Welding platform 1, described welding platform 1 comprises installation frame 11, is arranged side by side on described installation frame 11 and is used for accepting several groups of receiving troughs 12 of long steel bar, corresponding elastic sliding is arranged in the pusher that is arranged in described receiving trough 12 A rod 13 and a drive assembly 14 that drives the push rod 13 to move;

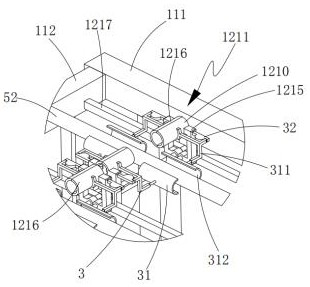

[0041]The positioning device 2, the short steel bar positioning assembly 2 is provided in one-to-one correspondence with the receiving trough 12, which includes several sets of positioning assemblies 121 arranged at intervals along the axial direction of the receiving chute 12; the positioning assembly 121 includes symmetrical The positioning mechanism 1211 arranged on both sides of the radial direction of the receiving trough 12, the power mechanism 1213 that is arranged in one-to-o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com