Automobile antenna support forming method

A molding method and technology for automotive antennas are applied in the field of stamping processing, which can solve the problems of complex structure and adverse effects of metal material flow, and achieve the effect of ensuring accuracy requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

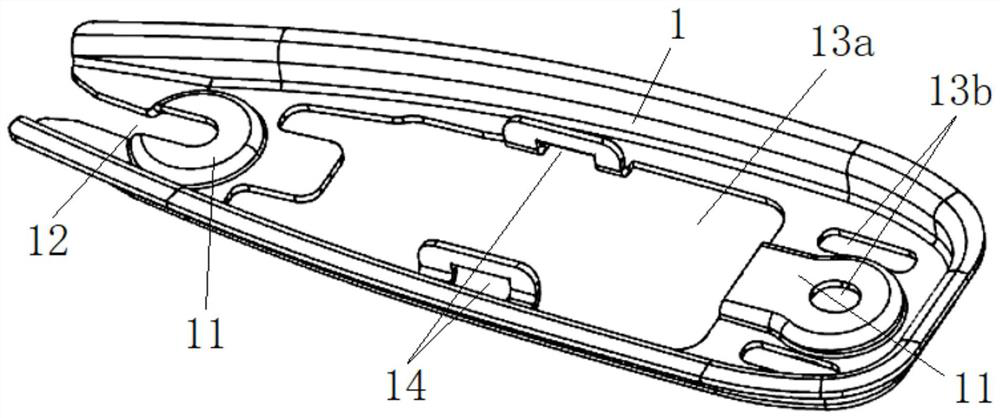

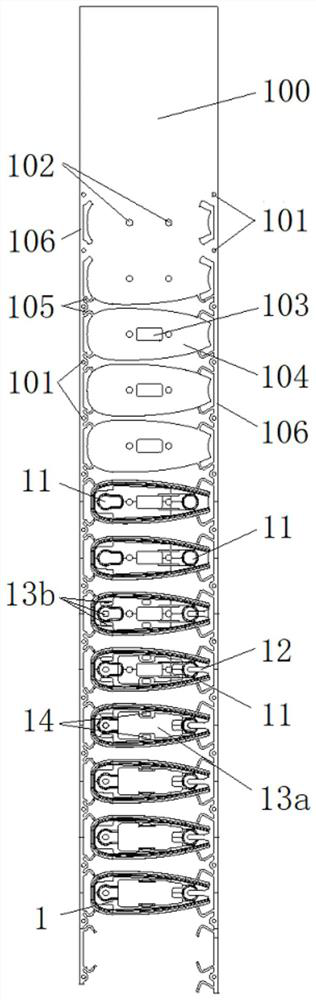

[0028] like figure 1 and figure 2 Shown, a kind of automobile antenna support molding method of the present invention, the step comprises:

[0029] ① Cut out outer positioning holes 101 on both sides of the metal strip 100 . The outer positioning hole 101 is used as a positioning reference on the continuous part 106 to allow each stamping of the continuous die to locate the outer position.

[0030] ② Cut out the outer contour of the core part 104 on the metal strip 100 with a reserved amount of deformation, and let the core part 104 be connected to the continuous parts 106 on both sides of the metal strip 100 by means of several connecting materials 105 .

[0031] ③ Punch out the deformation reserved hole 103 in the middle of the core part 104 . The scope of the deformation reserved hole 103 is inside the scope of the large through hole 13a, but smaller. The purpose of this is to allow the middle material to flow outwards during the convex hulling process but not exceed th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com