Aromatic co-polyimide gas separation membranes derived from 6fda-6fpda-type homo-polyimides

A technology of 6FDA and block copolymers, which is applied in gas treatment, gas fuel, separation methods, etc., and can solve problems such as inefficiency and impracticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Example 1 shows the synthesis of certain random and block copolymerized polyimides from 6FDA, 6FpDA and tetramethyl-p-phenylenediamine. Example 2 shows the synthesis of certain random copolyimides from 6FDA, 6FpDA and CARDO. Examples 3 to 5 tested the properties of these random and block copolymerized polyimides as membranes for aggressive natural gas separations. For example, Table 3 shows the high permeability and selectivity of the membranes to the non-methane components of the natural gas stream.

[0078] In order to illustrate embodiments of the present invention, the following examples are given, however, it should be understood that these examples are merely illustrative in nature and that embodiments of the present invention are not necessarily limited thereto.

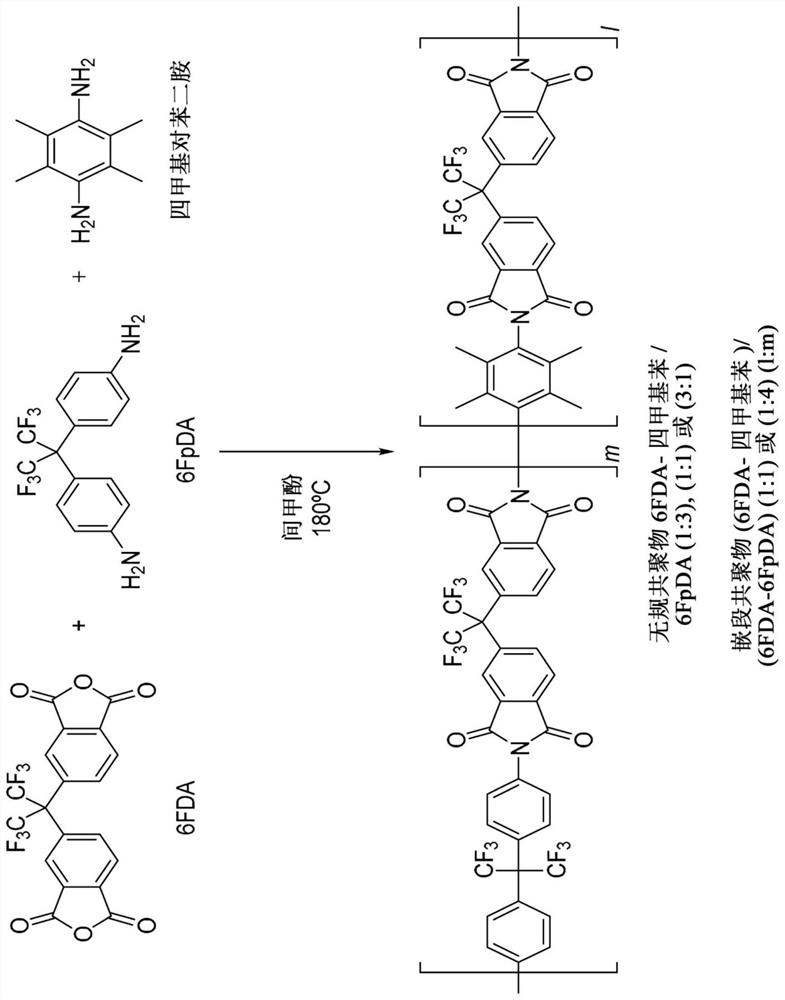

[0079] Example 1: Preparation of aromatic copolymerized polyimide random 6FDA-tetramethylbenzene / 6FpDA and block (6FDA-tetramethylbenzene) / (6FDA-6FpDA).

[0080] From 2,2'-bis-(3,4-dicarboxyphenyl)hex...

Embodiment 2

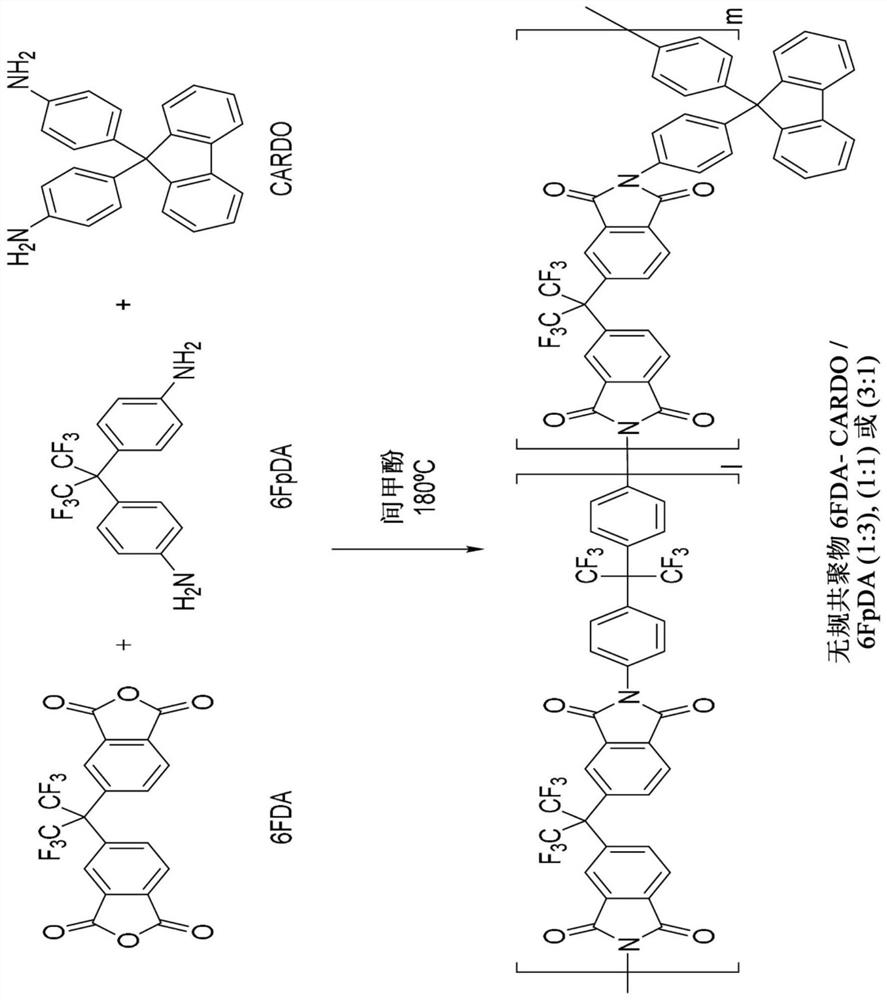

[0086] Example 2: Preparation of aromatic random copolymerized polyimide 6FDA-CARDO / 6FpDA.

[0087] From 2,2'-bis-(3,4-dicarboxyphenyl)hexafluoropropane dianhydride (6FDA) (also known as 4,4'-(hexafluoroisopropylidene)diphthalic anhydride) according to the following procedure (obtained from Alfa Aesar); 9,9-bis(4-aminophenyl)fluorene (CARDO) (obtained from TCIA America); and 4,4'-(hexafluoroisopropylidene)diphenylamine (6FpDA) (obtained from obtained from TCI America) for the synthesis of a series of random aromatic 6FDA-CARDO / 6FpDA copolyimides (see for example figure 2 ). Solvents used included methanol (obtained from ThermoFisher Scientific) and m-cresol (obtained from Alfa Aesar). All chemicals and solvents used in the studies were used without further purification.

[0088] The random copolymer polyimide 6FDA-CARDO / 6FpDA (1:1) (mmol CARDO:mmol 6FpDA) (VI) was synthesized as follows: In a 100 mL three-necked round bottom flask equipped with nitrogen inlet and mechanica...

Embodiment 3

[0104] Embodiment 3: CO 2 / CH 4 、He / CH 4 and N 2 / CH 4 Evaluation of pure gas separation performance.

[0105] Measured and calculated through a series of copolyimide 6FDA-Tetramethylbenzene / 6FpDA and 6FDA-CARDO / 6FpDA membranes including He, CO at up to 300 psig upstream pressure and 35°C 2 、CH 4 and N 2 Permeability coefficients for pure gases, and including He / CH 4 , N 2 / CH 4 and CO 2 / CH 4 Ideal selectivity for gas pairs. The results for the two copolymers are shown in Tables 3 to 4 and Tables 7 to 8, respectively. The depicted permeability properties for all permeated gases are the average of at least two or more measurements, and the error of the permeability coefficient is less than ±5% of the indicated value.

[0106] For random copolymerized polyimides, the content of 6FpDA in the copolymers was varied from 25% to 75% (3:1 to 1:3) to study the effect of segmental part changes on the transport properties of the copolymers. As can be observed in Tables 3 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| permeability | aaaaa | aaaaa |

| permeability | aaaaa | aaaaa |

| permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com