Stratum simulation device and crack plugging instrument

A technology for simulating devices and formations, applied in the field of drilling fluid plugging test, which can solve problems such as difficult operation, inability to comprehensively evaluate plugging formula, formation loss channels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

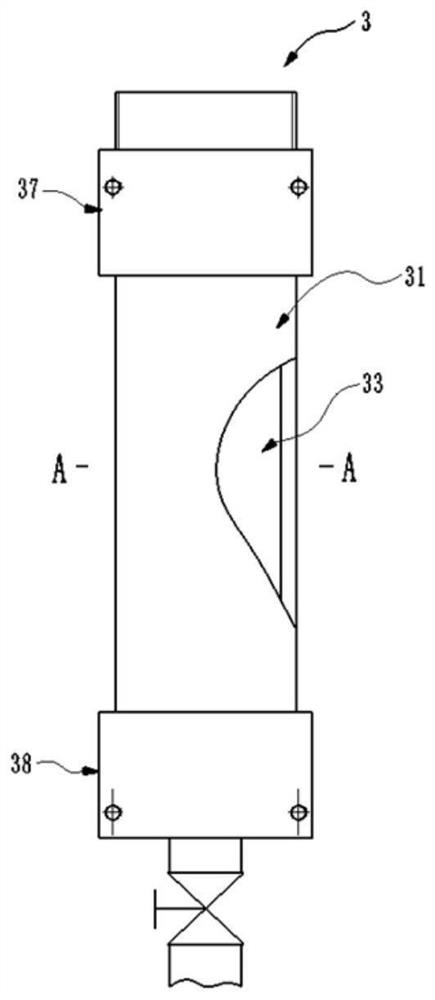

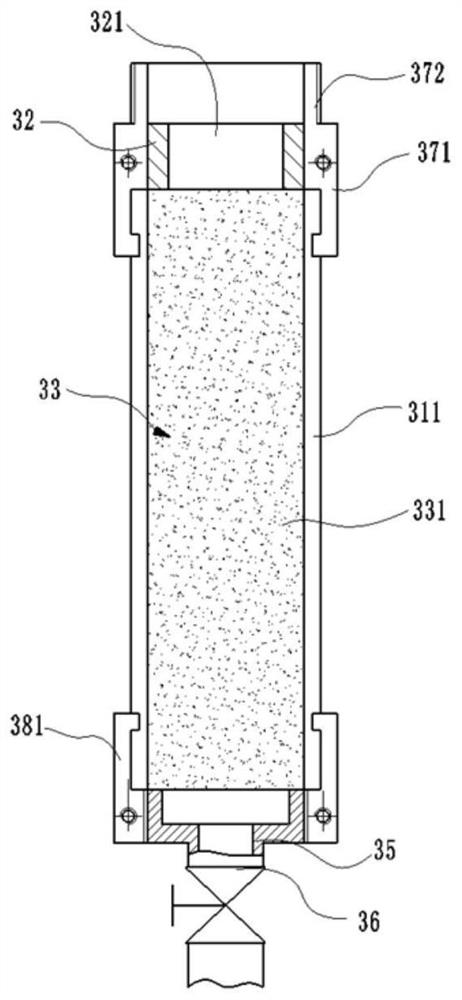

[0035] refer to Figure 1 - Figure 2 As shown, a forma simulation device includes a slit plate base 31, a hole plate 32, a slit plate body 33, and a clamp assembly.

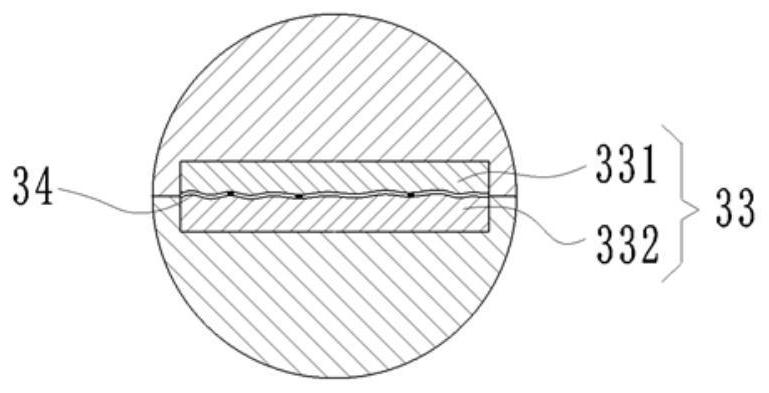

[0036] refer to Figure 1 - Figure 2 As shown, the slit plate body 33 includes two plates 332, and the first slit plate 331 and the second slit plate 332, the slit plate body 33, and the first slit plate 331, and the second slit plate 332 are two plates constituting the crack 34. A gap is formed between the dock plate 332, which is a crack 34, in order to make the crack 34 more true, the first slit plate 331 is provided with a plurality of bumps, the second sewing plate 332 towards one side of the second slit plate 332. A plurality of grooves are provided on one side of the first slit 331, and the plurality of protrusions can be adapted to each other; the grooves and projections are formed by three-dimensional laser etching. Figure 5 The degraded texture of etching according to the true crack form is formed, which form...

Embodiment 2

[0053] refer to Figure 8 As shown, a crack shower, which includes a wellbore simulation device 1, a carrier power test device 2, a data acquisition and processing apparatus, a formation simulation device 3 in the above-described embodiment; wherein the pressure relief capability test device 2 is connected. To the inner cavity of the wellbore simulation device 1, the working fluid is added to the wellbore simulation device 1 and provide an alternate pressure for the wellbore simulation device 1; the wellbore simulation device 1 is used to accommodate the plug-in material and simulate the environment in the loophole to establish a leak process. The outlet end of the wellbore simulation apparatus 1 is connected to the formation simulation device 3, and the wellbore simulation device 1 will push the plug material through the pressing capacity test device 2 to the leak passage of the formation simulation device 3; data acquisition and processing device and The wellbore simulation appar...

Embodiment 3

[0064] After the wellbore simulation apparatus 1 and the formation dielectric device 3 in the above Example 2, the retrofitability test device 4 can be connected at the liquid tube 35 of the formation simulation device 3, and the return capacity test device 4 includes a circulating mud pump 42 and The buffer container 41, the circulating mud pump 42 and the buffer container 41 are connected to the yards 35 of the formation simulation apparatus 3 connected to the formation, and construct the return capacity test device.

[0065] The return capacity testing process is to connect the liquid tube 35 of the formation simulation device 3 to the retrofitability test device 4, and inverted the mud or clean water through the circulating mud pump 42, into the formation simulation device 3, by metering formation simulation device 3 into liquid The amount of liquid at the end calculates the return to the plug material, thus testing the retrofitability of the formation simulation module 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com