Quartz tube straightening device and straightening method

A technology of quartz tube and tube alignment, which is applied in glass reshaping, glass manufacturing equipment, glass molding, etc. It can solve problems such as low efficiency, unstable quality, and long alignment time, and achieve simple operation and avoid excessive speed. Fast, guaranteed effect of moving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

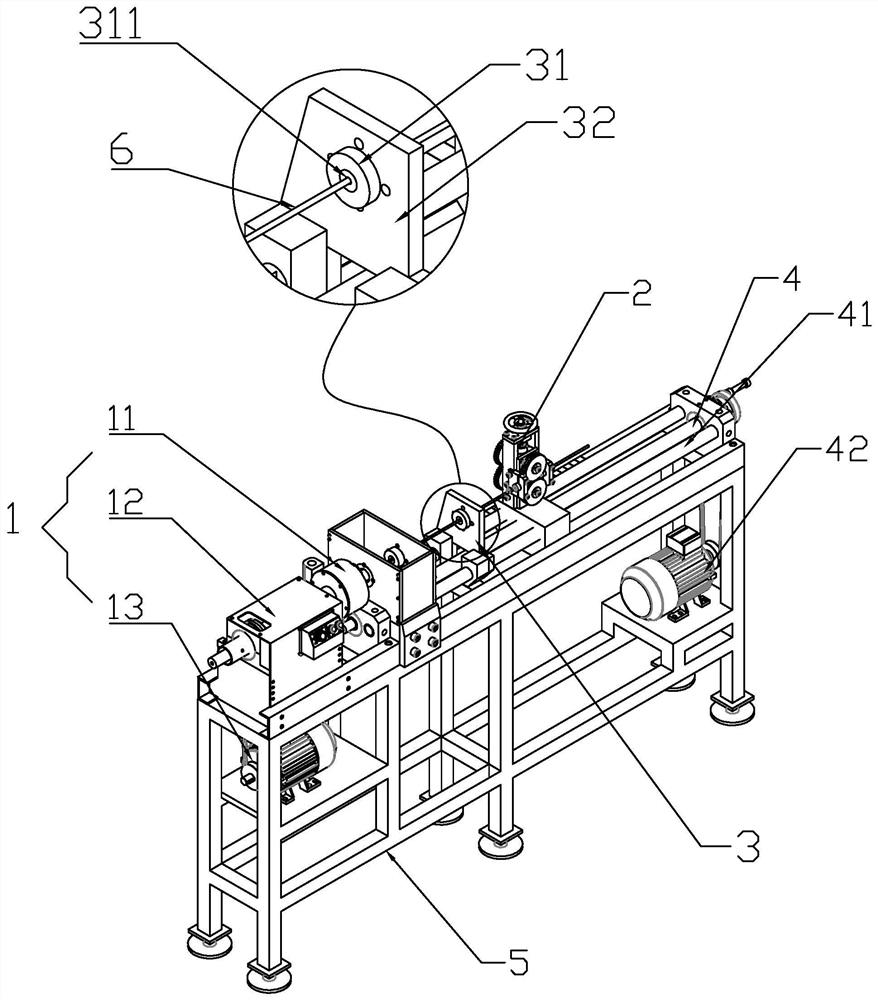

[0036] Such as figure 1 Shown, a kind of quartz tube straightening device comprises:

[0037] Workbench 5, height adjustment feet are provided at the bottom of workbench 5, and two horizontal guide columns 41 are arranged on the workbench 5 along the length direction;

[0038] The clamping mechanism 1 is arranged on one end of the workbench 5, and is used to clamp one end of the quartz tube and make it rotate along the axis. The clamping mechanism 1 includes a three-jaw chuck 11, a spindle box 12 and a first motor 13. The first motor 13 Drive the main shaft in the spindle box 12 to rotate, thereby driving the three-jaw chuck 11 to rotate, and the jaws of the chuck are made of graphite;

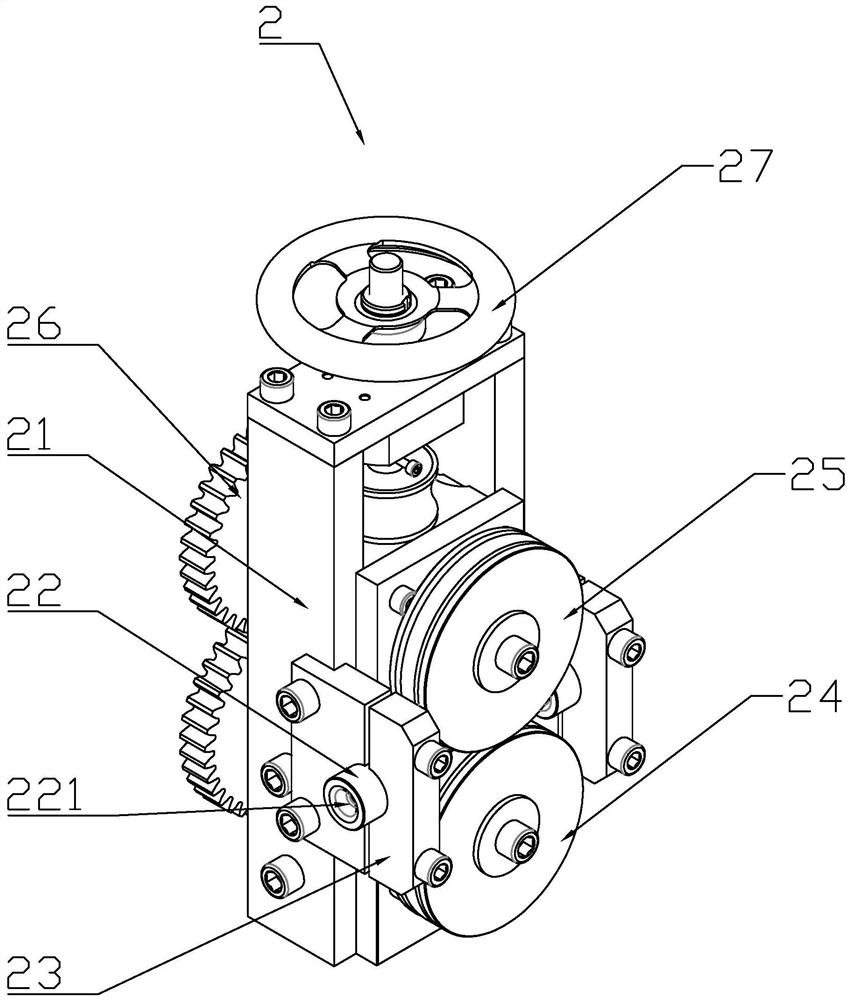

[0039] Lifting mechanism 2, the lifting mechanism 2 is slidingly arranged on the guide column 41, and is arranged on the end of the quartz tube away from the clamping mechanism 1, used to lift the quartz tube and ensure that the quartz tube extends in the axial direction, the lifting mechanis...

Embodiment 2

[0042] A quartz tube straightening device, its structure is roughly the same as that of Embodiment 1, the difference is that it also includes a servo screw drive mechanism for driving and controlling the moving speed of the straightening plate 31, and the two inner walls of the first straightening hole 311 There are two annular pressure sensors along the circumference respectively.

[0043] Compared with Embodiment 1, the straightening plate 31 is automatically controlled.

Embodiment 3

[0045] A method for straightening a quartz tube, comprising the steps of:

[0046] a1. Replace the first straightening piece 31 and the second straightening piece 22 with suitable ones according to the size of the quartz tube 6 (the aperture is slightly larger than the outer diameter of the quartz tube), clamp one end of the quartz tube on the three-jaw chuck 11, and put the straightening plate 31 Move to any end, and the other end of the quartz tube passes through the first alignment hole 311 and the second alignment hole 221 in turn, and then places it on the reference roller 24;

[0047] a2. Drive the first motor 42 according to the length of the quartz tube to adjust the position of the lifting mechanism 2 to ensure that the longest possible quartz tube can be straightened;

[0048] a3. Rotate the adjustment hand wheel 27 to adjust the height of the follower roller 25 to ensure that the quartz tube is not clamped by the upper and lower rollers, can pass through the space b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com